Dedicated base of fault simulation comprehensive experiment table for machine driven system

A technology for mechanical transmission system and fault simulation, which is applied in the testing of machine gear/transmission mechanism, mechanical bearing testing, and testing of machine/structural components, etc. It can solve problems such as insufficient functions, complicated operation, and bulky appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

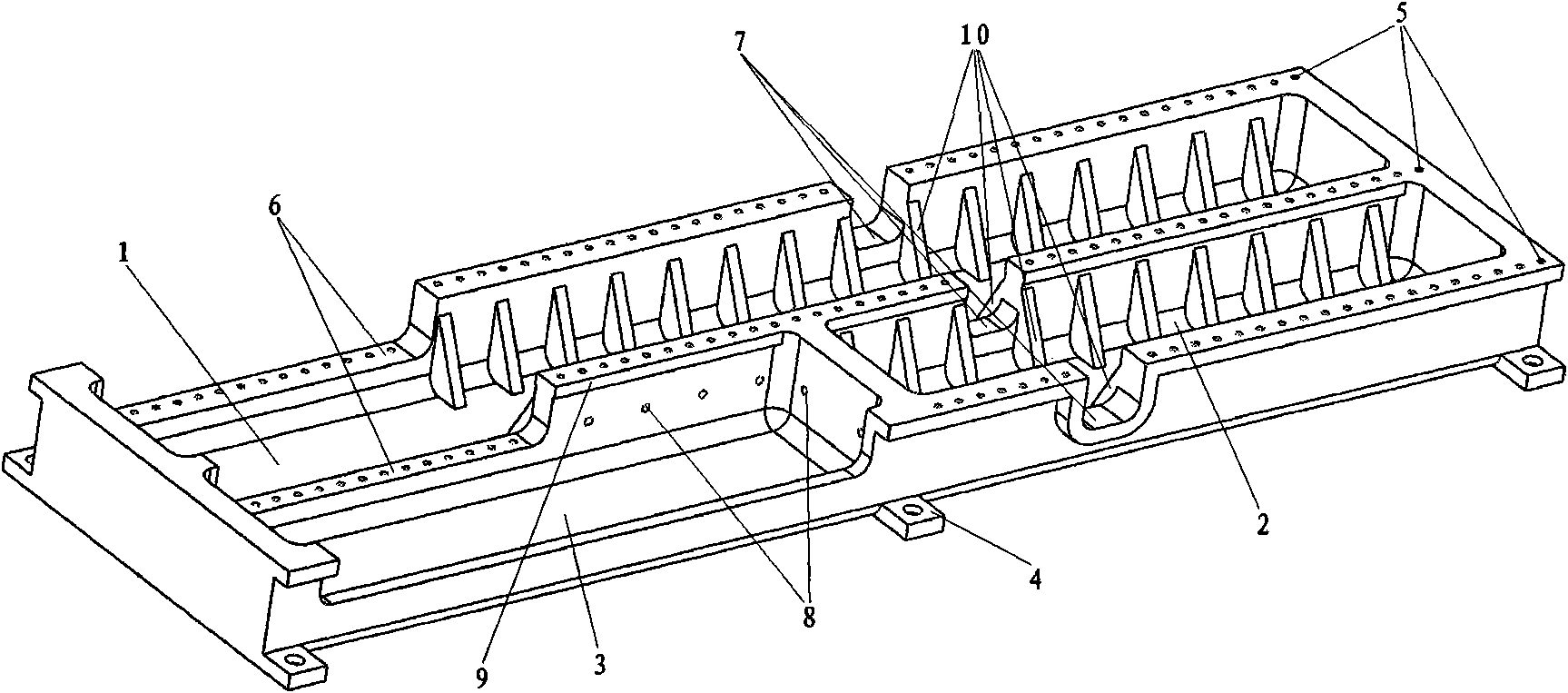

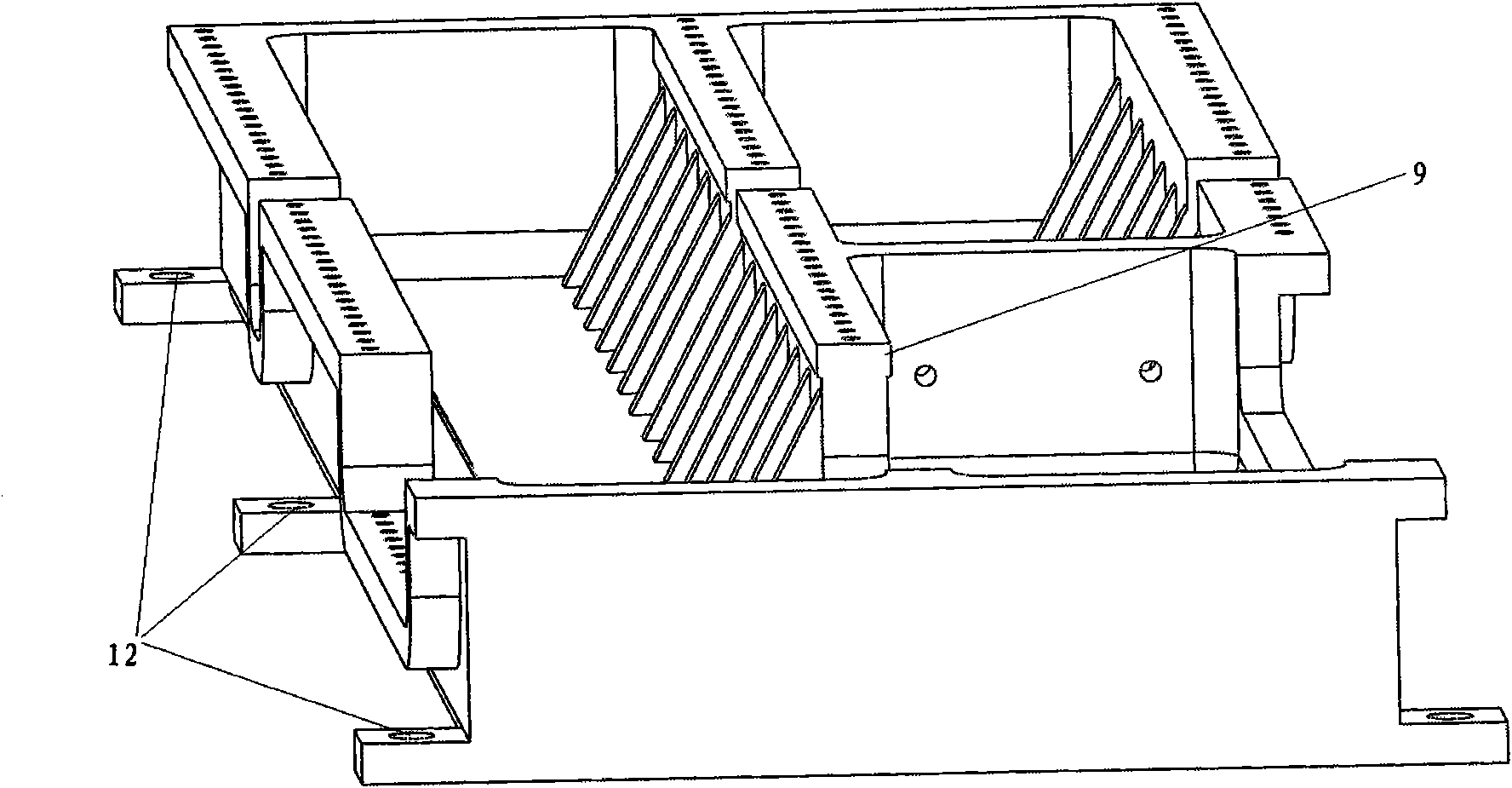

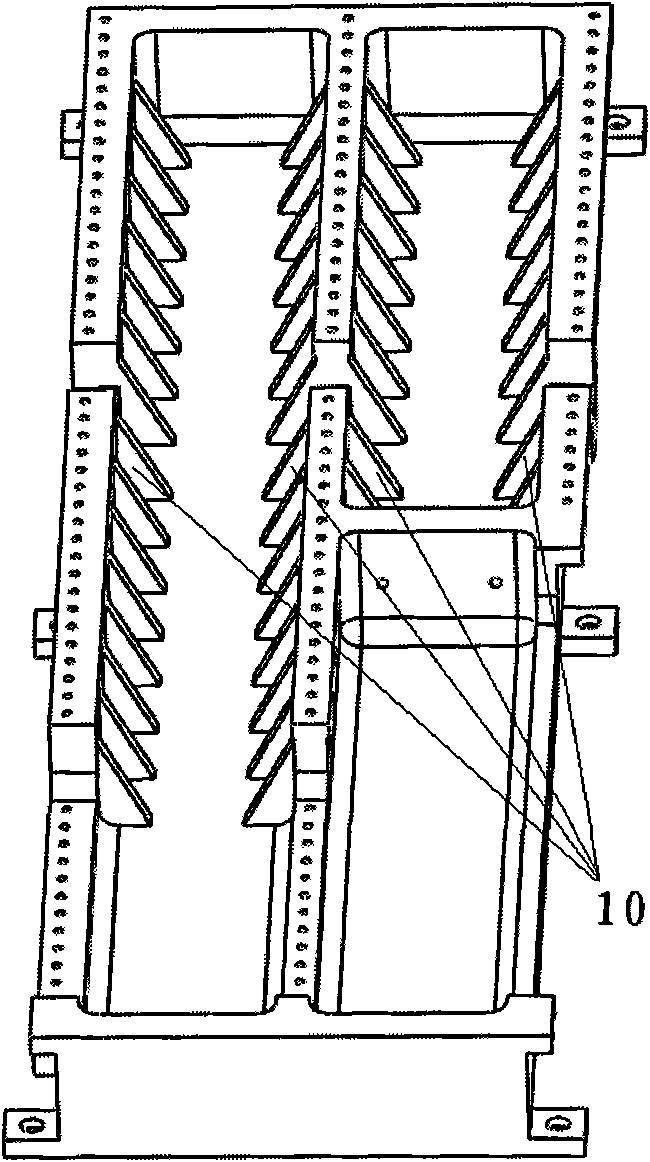

[0019] Such as figure 1 The shown special base of a mechanical transmission system failure simulation comprehensive test bench is composed of a first guide slot 1 , a second guide slot 2 , a power distribution slot 3 and a foot 4 . The first guide groove 1 is used for installing the motor, shaft coupling, shaft, bearing housing, counterweight plate and pinion. The second guide groove 2 is used to install the bull gear, the bearing seat, the shaft coupling and the brake. The power distribution slot 3 is used for installing motor controllers, brake controllers, and data cable adapters. A counterbore 12 is respectively designed on the legs 4 for fixing the base and the foundation by bolts, and the counterbore can make the test bench beautiful and simple after complete assembly. The bottom of the base is a sun-shaped bottom surface 11 . A boss 9 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com