Method for preparing capillary inner wall coating

A capillary and coating technology, which is applied in the field of preparation of capillary inner wall coating, can solve the problems of capillary blockage, complicated preparation, and many influencing factors, and achieves the effects of high reusability, simple preparation method and good coating stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

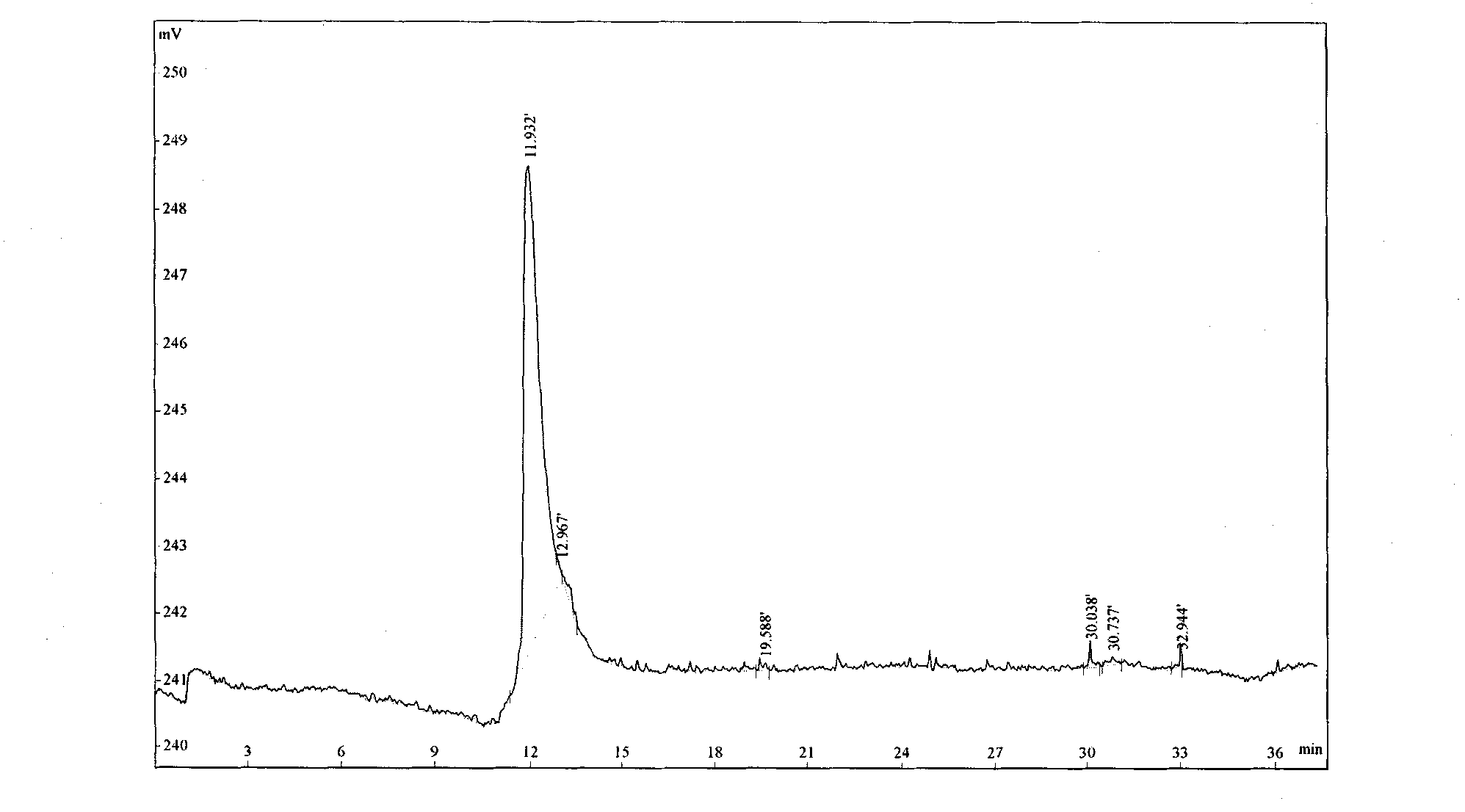

[0016] Example 1: Take an unused quartz capillary with an inner diameter of 50um, an outer diameter of 360um, and a length of 70cm. The capillary was cleaned with 50 mM citric acid solution for 2 minutes; then, a 3% polyethylene glycol 2000 coating buffer solution was slowly injected into the aforementioned capillary; until three drops flowed out from the other end of the capillary, the preparation of the coating was completed. The test effect will be better if the coated capillary filled with coating buffer is left for 12 hours. Carry out the experimental test of electrophoresis separation lactoferrin below:

[0017] (1) Experimental conditions:

[0018] Materials: the prepared capillary of Example 1, three samples of lactoferrin;

[0019] Electrophoresis operating conditions: PH value: 2.2; voltage: 16KV; current: 12uA; wavelength: 214nm

[0020] (2) Data processing table obtained from the experiment

[0021] Injection sequence number

example 2

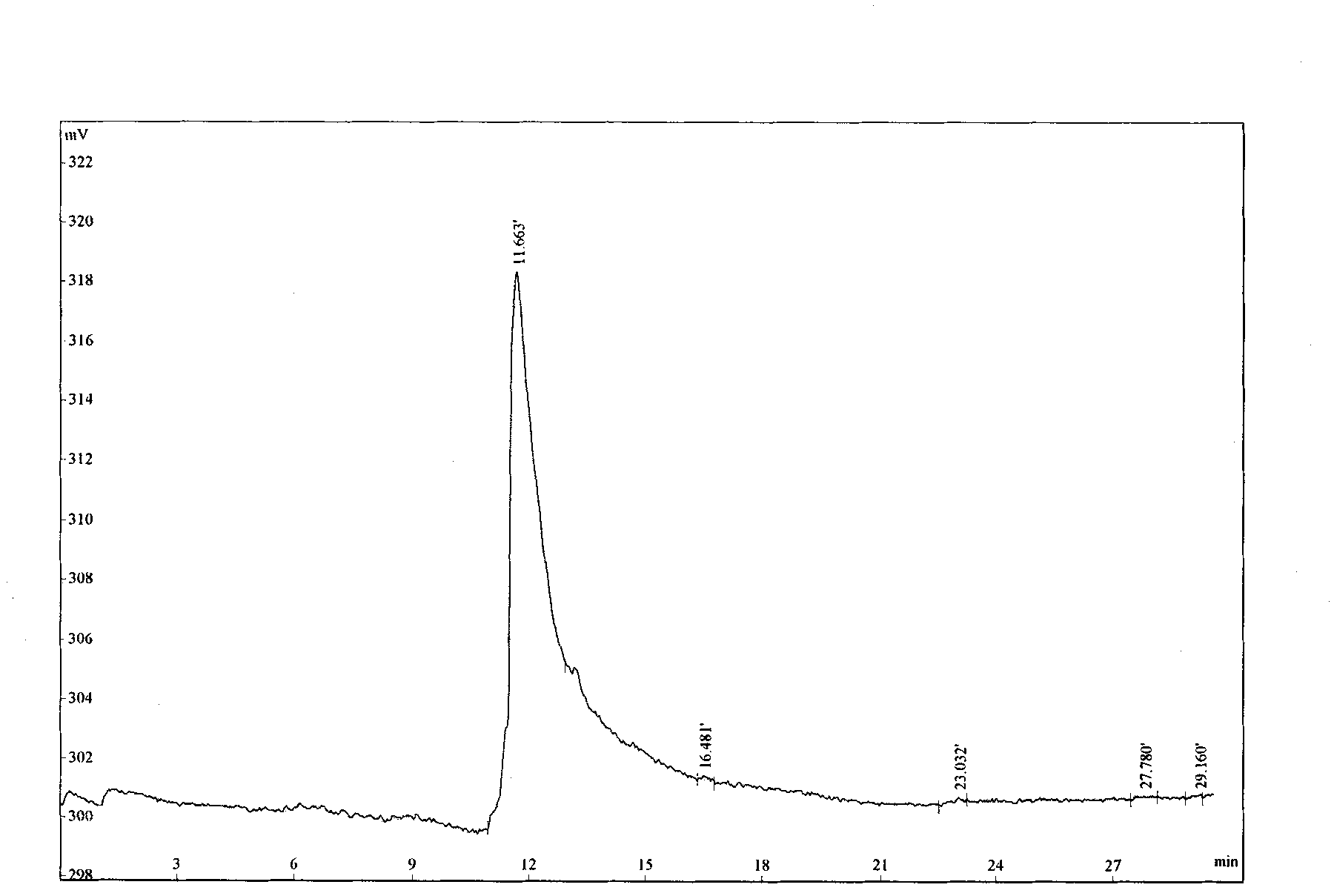

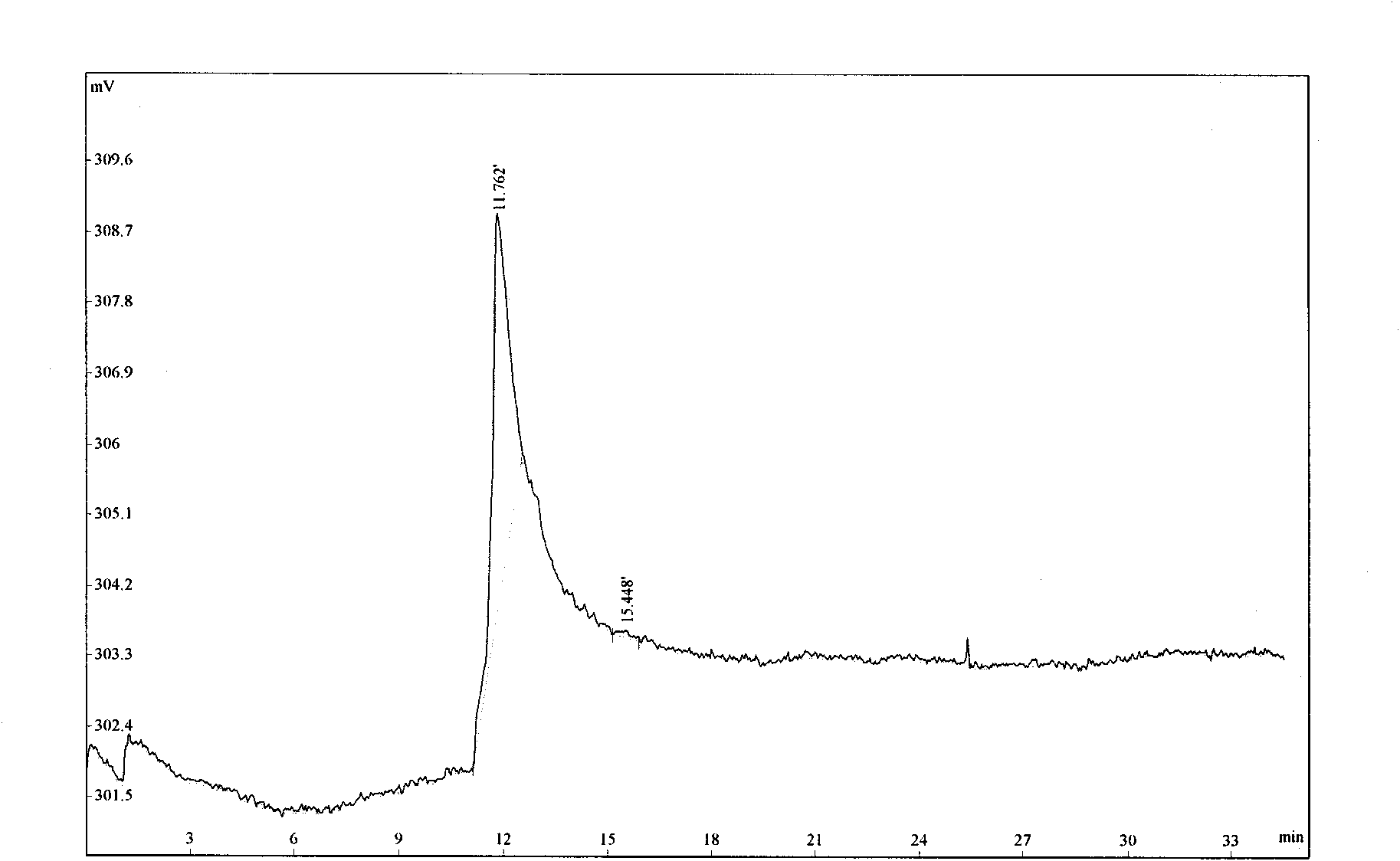

[0022] Example 2: Take an unused quartz capillary with an inner diameter of 50um, an outer diameter of 360um, and a length of 70cm. The effective length is 60cm (the length from the injection port to the detection window). Use a buffer solution with a pH of 2.2 and a concentration of Wash the capillary with 50mM citric acid solution for 2 minutes; take a few grams of polyethylene glycol 2000, dissolve it in 50mM citric acid solution at pH=2.2, and make a coating buffer solution with a concentration of polyethylene glycol 2000 of 3%. ; Dissolve the lactoferrin sample to be detected in the coating buffer; slowly inject the coating buffer containing the lactoferrin sample into the capillary; put the capillary filled with the protein sample and the coating buffer at a voltage of 16KV, Current: 12uA, wavelength: 214nm electrophoresis operating conditions, while completing the separation of protein samples, the preparation of the coating is completed. Three samples were taken and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com