Waste heat utilizing device for internal combustion engine

An internal combustion engine and radiator technology, which is applied to steam engine devices, internal combustion piston engines, and mufflers, etc., can solve the problems of poor heat exchange performance of radiators, increased ventilation resistance, and reduced radiator ventilation, and achieve improved energy recovery. Efficiency, the effect of reducing ventilation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, one embodiment of the present invention will be described first, starting with the first embodiment, using the drawings.

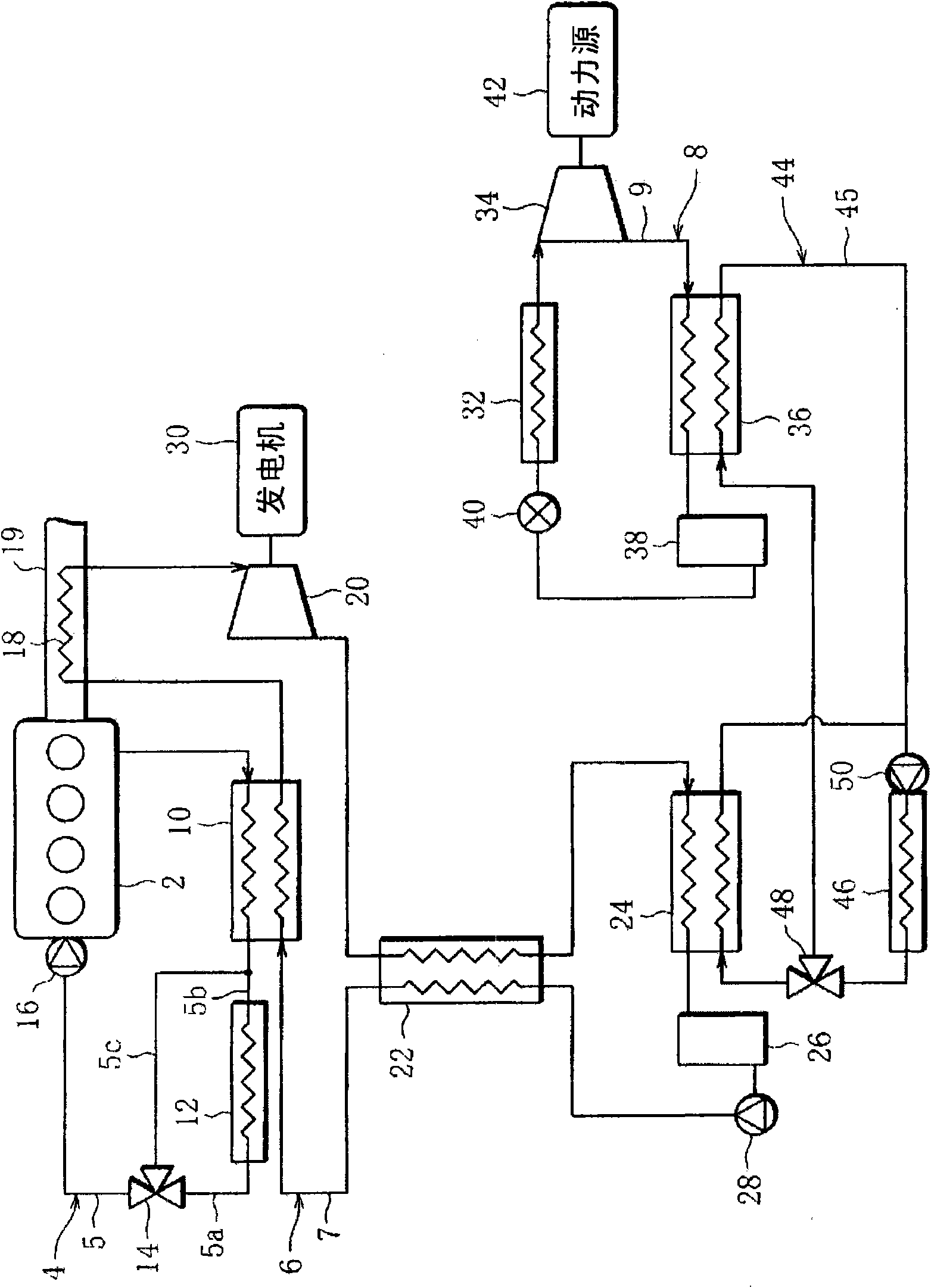

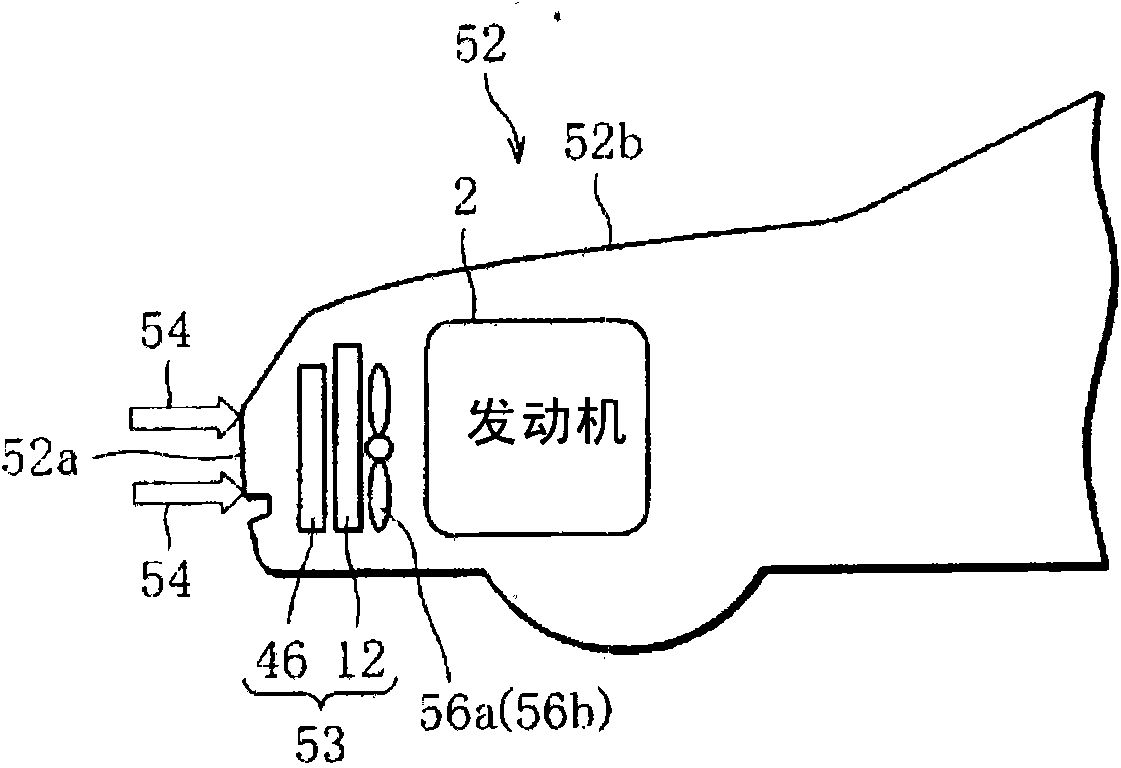

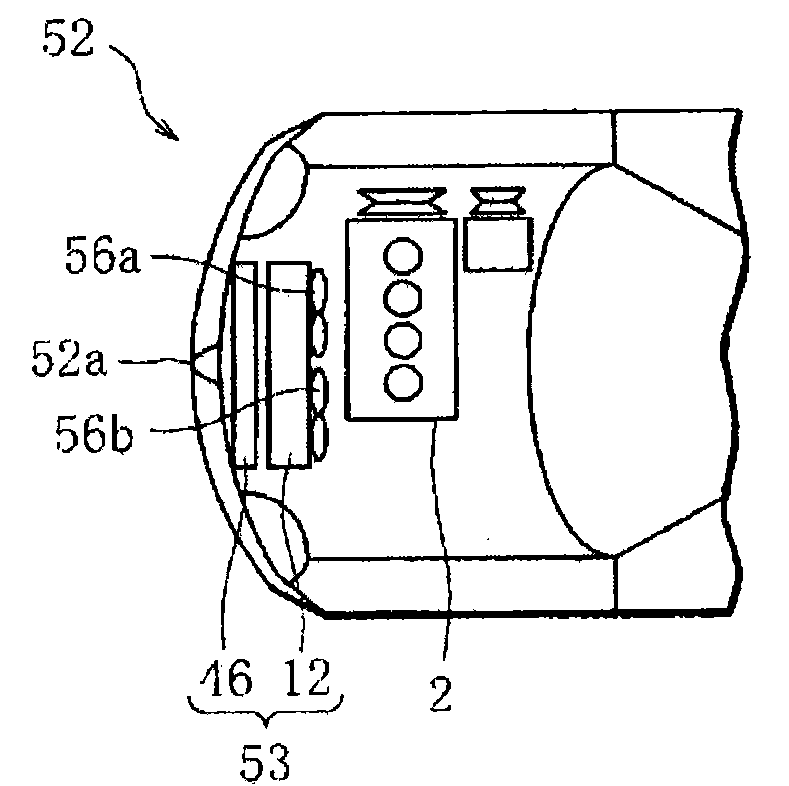

[0037] figure 1 It is a schematic diagram schematically showing the configuration of the waste heat utilization device of the internal combustion engine according to the present embodiment. The waste heat utilization device is installed in the vehicle, including: cooling water circuit 4, which cools the engine 2 of the vehicle; Rankine cycle circuit (Rankine cycle) 6 (hereinafter referred to as RC circuit), and the RC circuit 6 waste heat of the engine 2 is recovered; and an air-conditioning cycle (refrigeration cycle) 8 (hereinafter referred to as an AC circuit) for air-conditioning a vehicle interior (not shown).

[0038] In the cooling water circuit 4 , an evaporator 10 , a radiator 12 , a thermostat 14 , and a water pump 16 are connected sequentially from the cooling water flow direction to the cooling water circulation path 5 exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com