Purification technology of rokitamycin

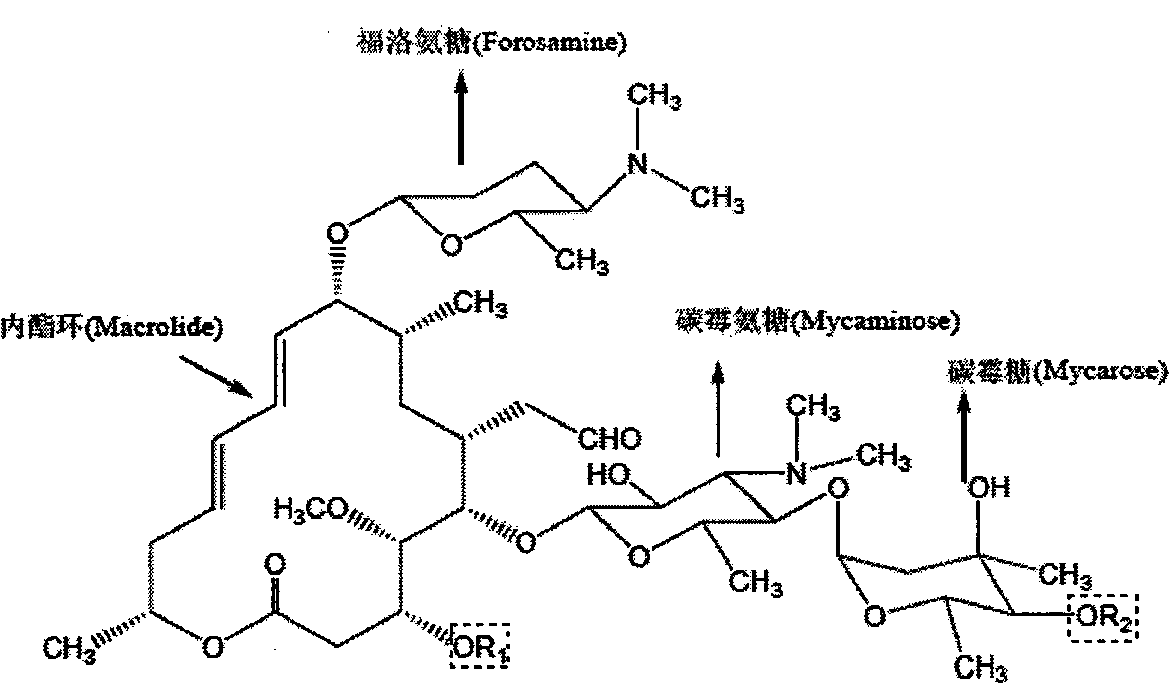

A karimycin and process technology, applied in the field of purification process for extracting karimycin, can solve the problem of less research on component purification, and achieve the effects of simple operation, improved quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

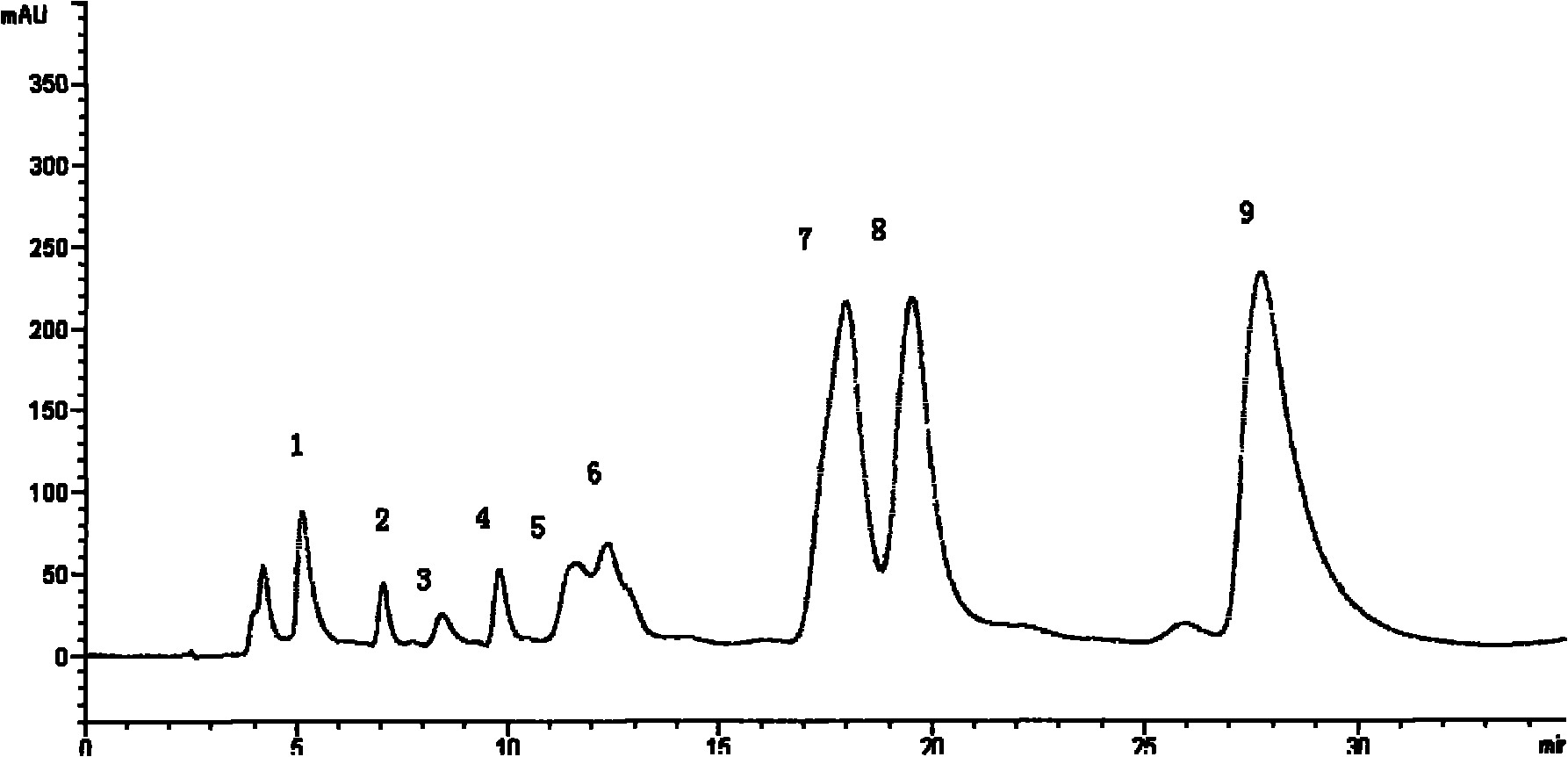

Embodiment 1

[0030] Add 150 g of polyaluminum chloride to 25 L of carrimycin fermentation broth (titer 796u / ml), filter with plate and frame, and obtain 37.5 L of filtrate. Add 1.46 L of butyl acetate to the filtrate, while stirring, add 6 mol / L NaOH solution to adjust the pH to 8.5, continue to stir for 30 min and then let stand, add NaCl and separate to obtain 1.13 L of ester phase extract. Sequentially use 280mL water, NaH with a mass concentration of 1% 2 PO 4 solution and water to wash the butyl ester extract. Add 310 mL of pure water to the butyl ester extract with a volume of 1.07 L after washing, add 3 mol / L hydrochloric acid solution to adjust the pH to 2.1 while stirring, continue stirring for 30 min, then stand still and separate layers to obtain 325 ml of aqueous phase extract. Add 2mol / L NaOH solution to adjust the pH to neutral, pass N 2 Blow for 5h. Add 2mol / L NaOH solution to the obtained 300ml aqueous phase extract to adjust the pH to 10.0, let stand, filter with sucti...

Embodiment 2

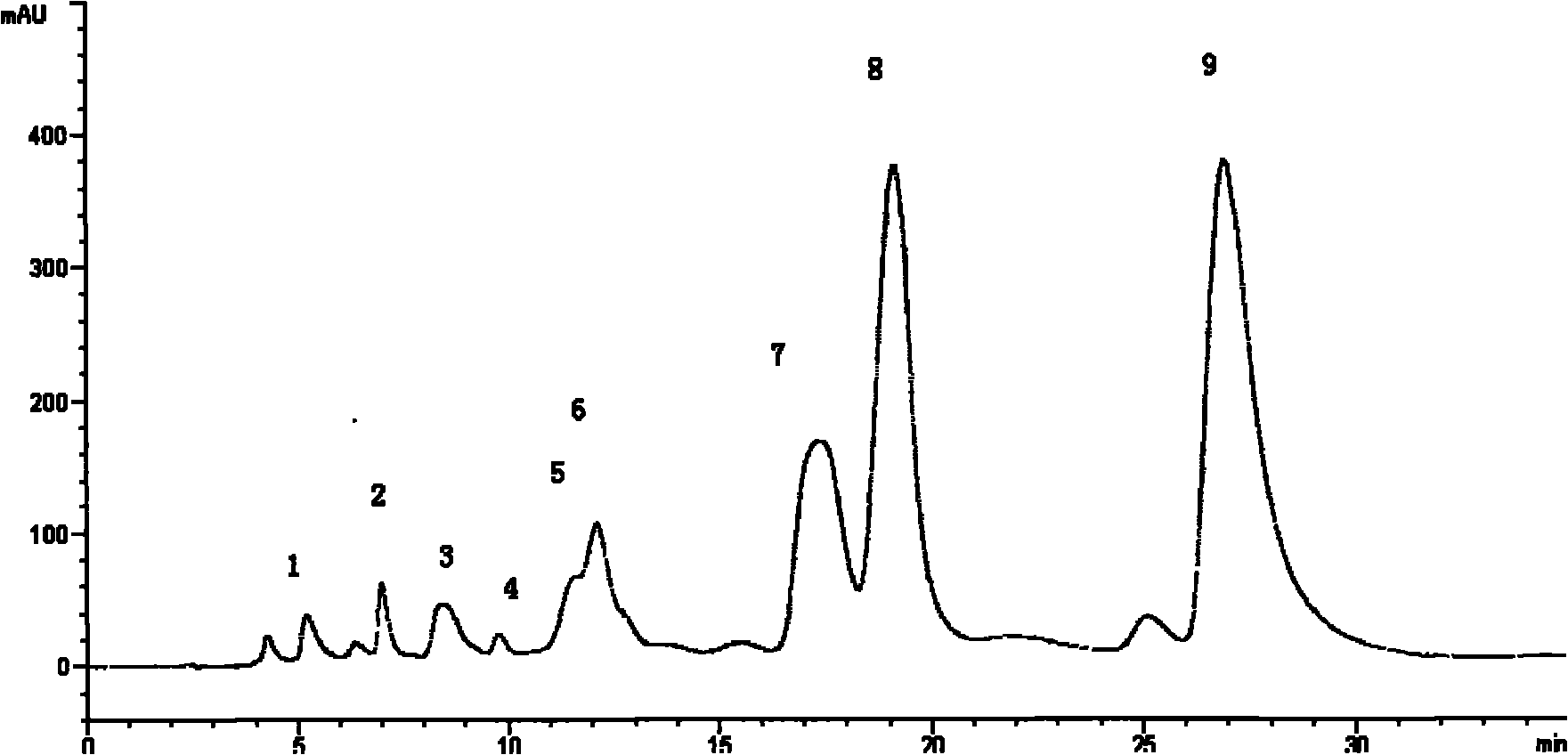

[0033] Add 125g of polyaluminum chloride to 25L of carrimycin fermentation broth (titer 1470u / ml), and filter with a plate frame to obtain 40L of filtrate. Add 3.5 L of butyl acetate to the filtrate, while stirring, add 6 mol / L NaOH solution to adjust the pH to 8.2, continue stirring for 30 min, then let stand, and obtain 2.98 L of ester phase extract by layering. Wash the ester phase extract once with 745ml water, then use 745ml mass concentration of 0.7% NaH 2 PO 4 The solution washes the ester phase extract twice. Adding mass concentration is 0.7% NaH in the extraction solution that volume is 2.86L after washing 2 PO 4 Solution 1L, while stirring, add 3mol / L hydrochloric acid solution to adjust the pH to 2.2, continue to stir for 30min, then stand still and separate layers to obtain 1.04L aqueous phase extract. Add 2mol / L NaOH solution to adjust the pH to neutral, pass N 2 Blow for 5h. Add 2mol / L NaOH solution to the obtained 1.18L extract to adjust the pH to 9.8, let...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com