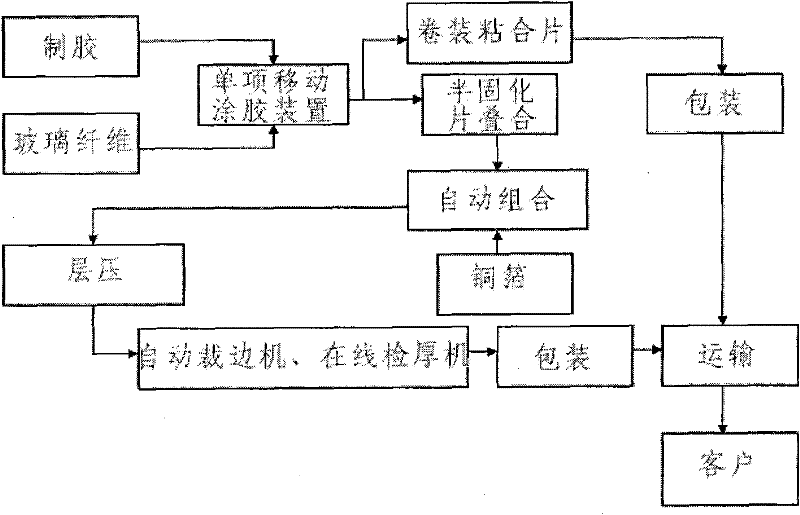

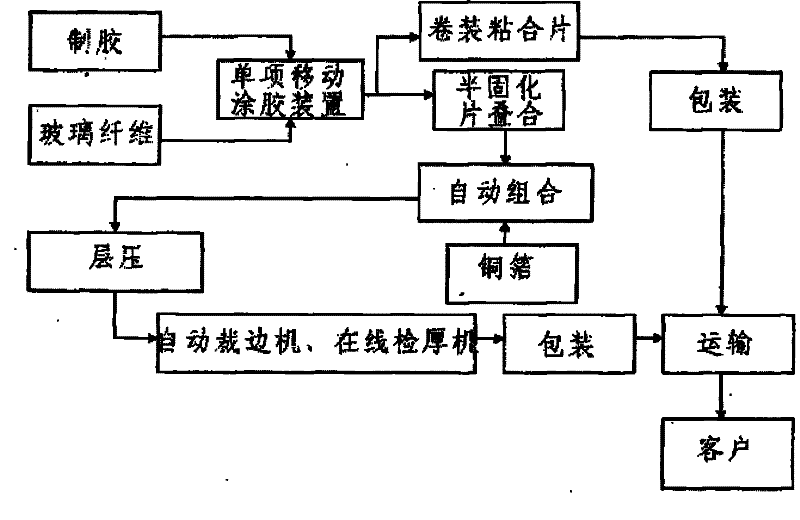

Material and production process for producing copper-clad plate

A production process and technology of copper clad laminates, applied in the field of materials and production processes for the production of copper clad laminates, to achieve the effect of eliminating air bubbles and uniform resin flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

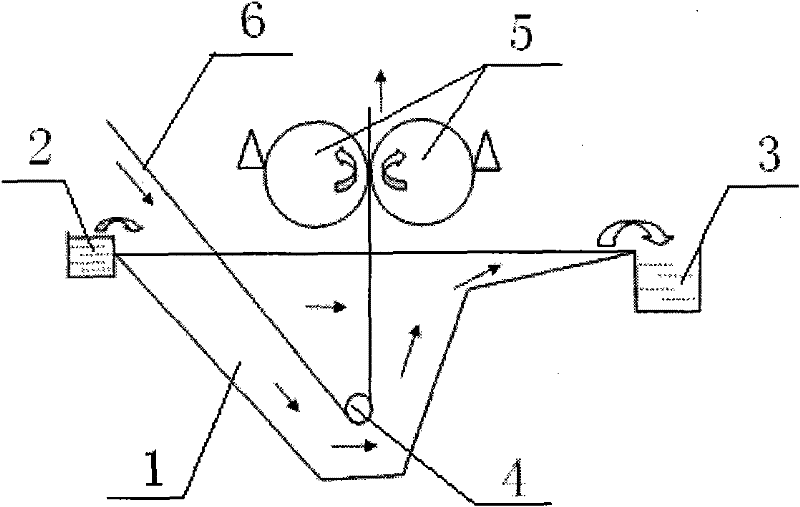

Method used

Image

Examples

Embodiment 1

[0029] The present invention is a material for producing copper clad laminates, the material includes glass fiber cloth, epoxy resin and copper foil, the epoxy resin is phosphorus / nitrogen epoxy resin, and inorganic resistive The flame retardant includes aluminum hydroxide powder and silicon powder in the inorganic flame retardant; among them, the glass fiber cloth is woven from untwisted open fiber glass fiber.

Embodiment 2

[0031] On the basis of Example 1, in order to ensure the quality of the copper clad laminate and make it have better flexibility, a preferred embodiment of the present invention is to control the particle size of aluminum hydroxide powder and silicon powder to 3000 mesh, Promptly select a kind of superfine aluminum hydroxide powder and supersoft silicon powder for use, all the other are identical with the technical scheme of embodiment 1.

Embodiment 3

[0033] On the basis of Example 2, because aluminum hydroxide has the advantages of good thermal stability, non-toxicity, no corrosive gas, less smoke generation, etc., and it is rich in resources and cheap in price, the preferred embodiment of the present invention also has the following advantages: , the weight percentage content of the inorganic flame retardant in the epoxy resin is 25%, the weight percentage content of the aluminum hydroxide powder in the inorganic flame retardant is 75%, and all the other technical schemes are identical with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com