Method for preparing 5182 big flat ingot with high performance by short flow process

A large slab, high-performance technology, applied in the field of smelting and casting of new non-ferrous metal materials, can solve the problems of high melt temperature of aluminum liquid, coarse slab grains, difficulty in Na removal technology, etc., and achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

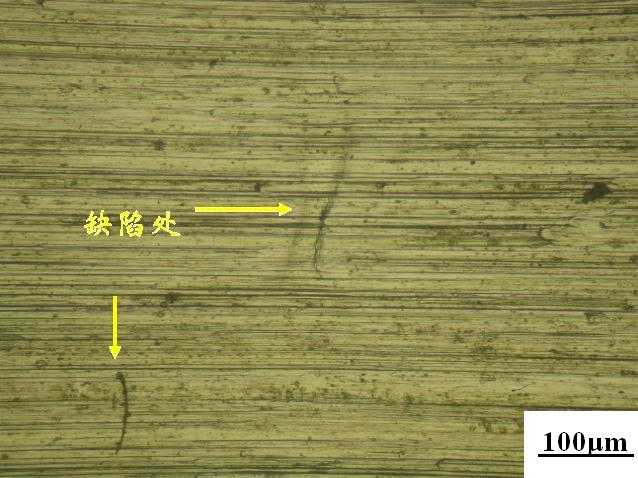

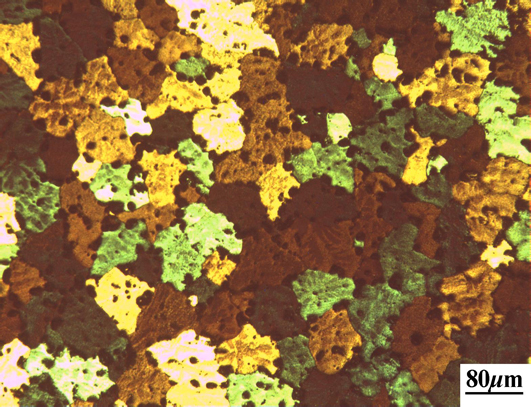

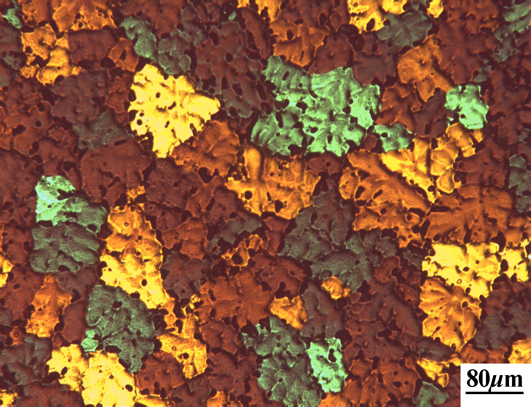

[0030] Example 1: The weighted contents of Fe and Si elements in electrolytic aluminum liquid and electrolytic remelted aluminum ingot are: 0.12% and 0.07%, respectively. The chemical composition of ingredients is: Mg4.9%; Mn0.36%; Fe0.17%; Cu0.05%; Si0.03%; Cr0.04%; Left and right control, Zn0.02%; electrolytic aluminum liquid ratio 40%, 5052 first-class waste 15%, Fe, Si, Mn and Cu are added in the form of master alloys, the amount added depends on the chemical composition of the ingredients, and the balance is electrolytic remelting Aluminum ingots. Feeding sequence: first add primary scrap, then electrolytically remelted aluminum ingots, Al-Cu master alloy, Al-Mn master alloy, Al-Si (add half first) and Al-Fe (add half first) master alloys, electrolytic Aluminum liquid; the rest of the intermediate alloy is added after the chemical on-line analysis in front of the furnace during the refining process, and Mg is added during the on-line refining process. Due to the low pro...

Embodiment 2

[0040] Example 2: The weighted contents of Fe and Si elements in electrolytic aluminum liquid and electrolytic remelted aluminum ingot are: 0.11% and 0.08%, respectively. The chemical composition of ingredients is: Mg5.0%; Mn0.35%; Fe0.19%; Cu0.05%; Si0.05%; Cr0.04%; Left and right control, Zn0.02%; electrolytic aluminum liquid ratio 68%, 5052 first-class waste 8%, Fe, Si, Mn and Cu are added in the form of master alloys, the amount added depends on the chemical composition of the ingredients, and the balance is electrolytic remelting Aluminum ingots. Feeding sequence: first add primary scrap, then electrolytically remelted aluminum ingots, Al-Cu master alloy, Al-Mn master alloy, Al-Si (add half first) and Al-Fe (add half first) master alloys, electrolytic Aluminum liquid; the remaining part of the intermediate alloy is added after the chemical online analysis in front of the furnace during the refining process, and the intermediate electrolytic aluminum liquid; Mg is added ...

Embodiment 3

[0046] Example 3: The weighted contents of Fe and Si elements in electrolytic aluminum liquid and electrolytic remelted aluminum ingot are: 0.12% and 0.09%, respectively. The chemical composition of ingredients is: Mg4.8%; Mn0.34%; Fe0.19%; Cu0.05%; Si0.03%; Cr0.04%; Left and right control, Zn0.02%; the proportion of electrolytic aluminum liquid is 49.5%, 5052 first-class waste is 12%, Fe, Si, Mn and Cu are added in the form of master alloys, the addition amount depends on the chemical composition of the ingredients, and the balance is electrolytic remelting Aluminum ingots. Feeding sequence: first add primary scrap, then electrolytically remelted aluminum ingots, Al-Cu master alloy, Al-Mn master alloy, Al-Si (add half first) and Al-Fe (add half first) master alloys, electrolytic Aluminum liquid; the remaining part of the intermediate alloy is added after the chemical online analysis in front of the furnace during the refining process, and the intermediate electrolytic alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com