Hot work tool steel and steel product using the same

A technology for thermal processing and tool steel, applied in the field of thermal processing tool steel and steel products made from it, can solve the problems of Si machinability deterioration, hardness or impact value reduction, Cr impact value reduction, etc., to reduce production Effects of cost, excellent thermal conductivity, and long mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0157] In order to prepare the respective inventive steel materials in Example B described below, Examples 1 to 5 were carried out to study the preferred contents of Si, Mn, Cr, Mo and V.

Embodiment 1

[0158] (Example 1: Research on Si content)

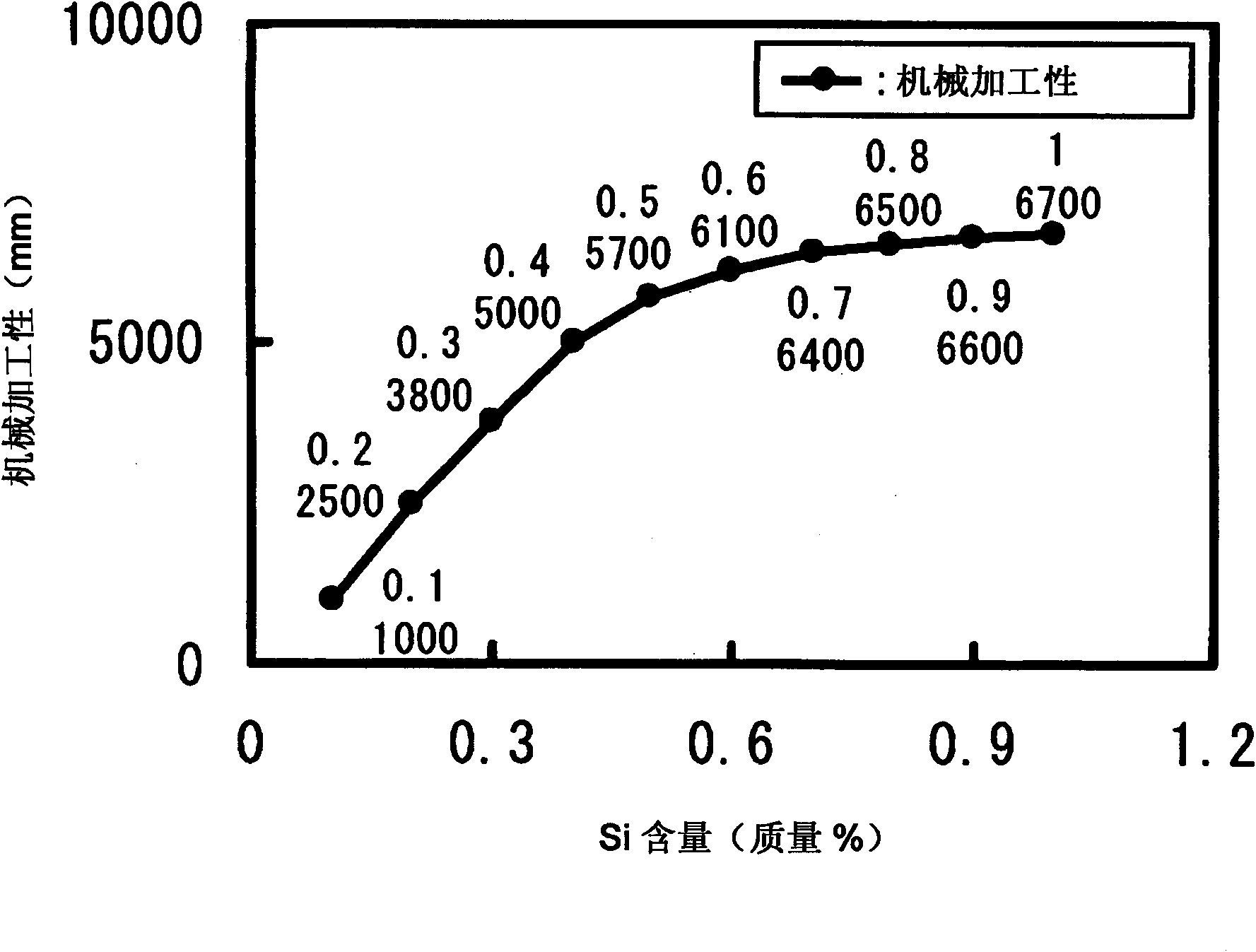

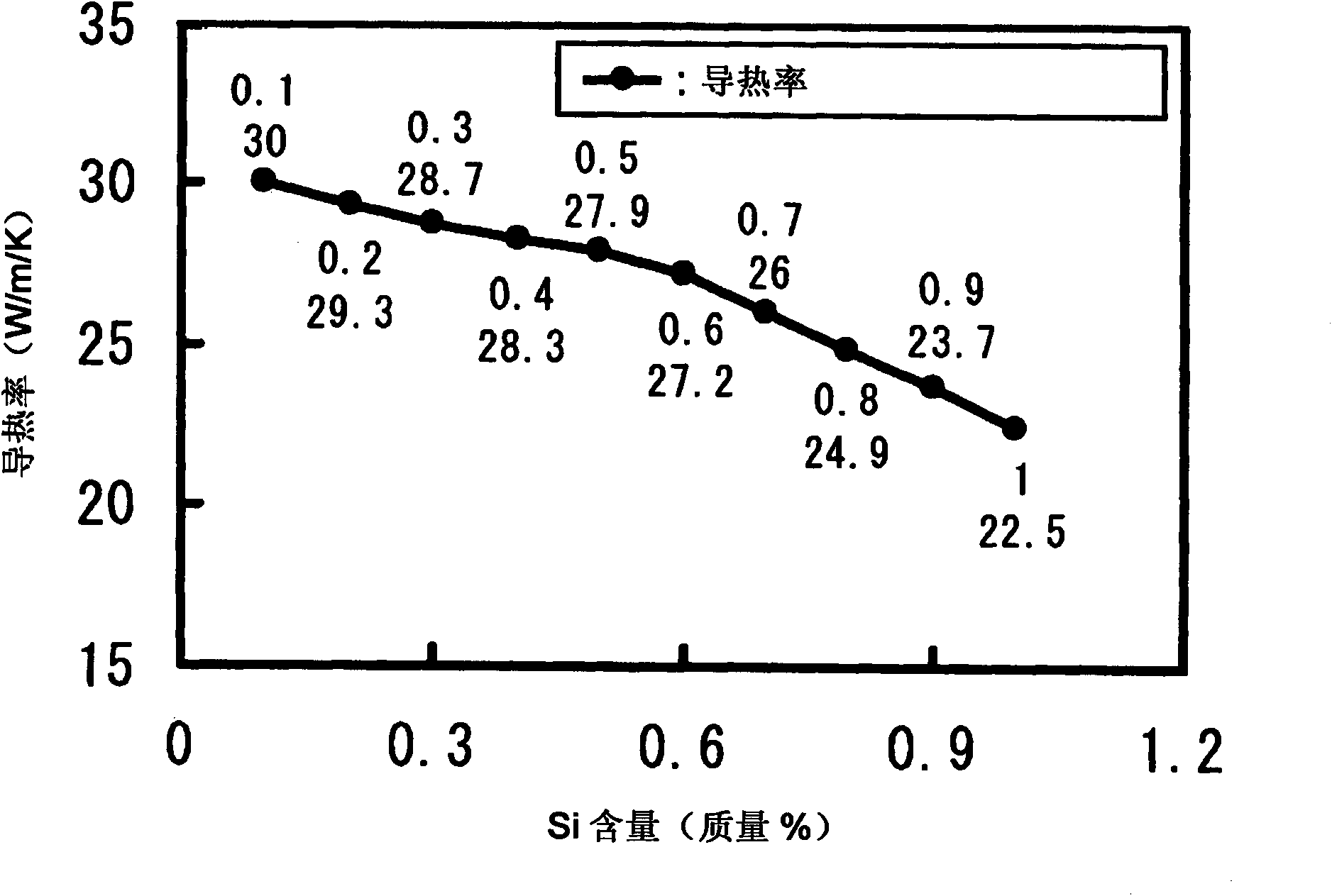

[0159] Study the preferred content of Si, and refer to figure 1 and 2 Make the following instructions.

[0160] figure 1 It shows that when cutting a steel material composed of 0.35 mass % of C, 0.82 mass % of Mn, 5.73 mass % of Cr, 1.21 mass % of Mo, 0.62 mass % of V and x mass % of Si, relative to Si Quantity, the distance cut by a cutting tool until the end of its life. exist figure 1 , with regard to the numerical values on the respective plot points, the numerical values on the upper side represent the x value (mass %), and the numerical values on the lower side represent the cut distance (mm). The sample used for evaluation of machinability was a 55mm×55mm×200mm square bar (which was manufactured according to the same procedure as in Example B and softened to a hardness of 90 to 97HRB by spheroidizing annealing), and the cutting tool The time when the maximum amount of wear on the end clearance surface reaches 300 ...

Embodiment 2

[0166] (Example 2: Research on Mn content)

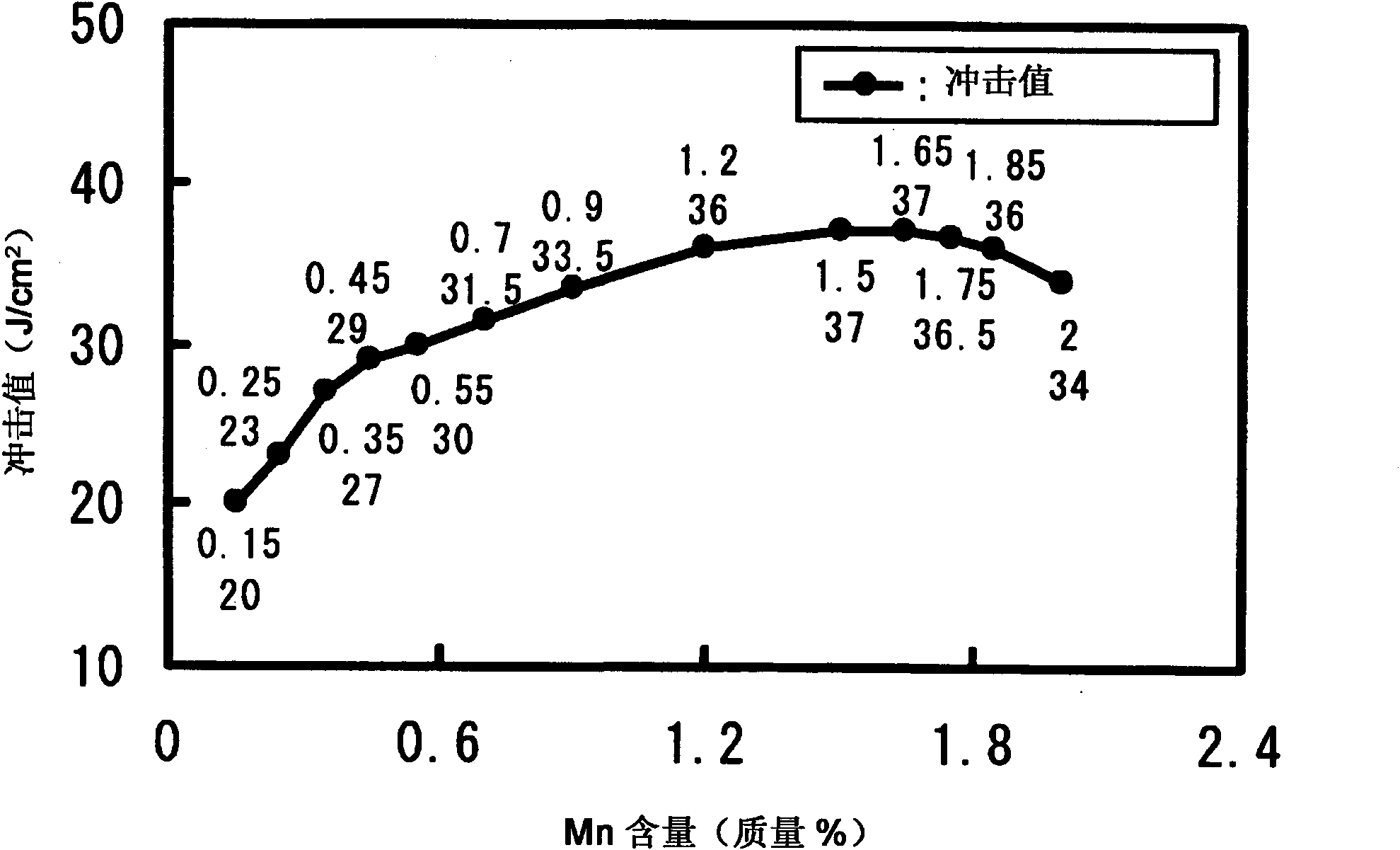

[0167] Study the preferred content of Mn, and refer to image 3 and Figure 4 Make the following instructions.

[0168] image 3 The impact value at room temperature is plotted against the content of Mn for a steel consisting of 0.32 mass % C, 0.42 mass % Si, 5.03 mass % Cr, 1.22 mass % Mo, 0.60 mass % Consists of V and x mass % of Mn. exist image 3 , with regard to the numerical values on the respective plot points, the numerical values on the upper side represent the x value (mass %), and the numerical values on the lower side represent the impact value (J / cm 2 ). The sample used to evaluate the impact value was a square bar of 11 mm × 11 mm × 55 mm (which was manufactured according to the same procedure as in Example B, and was softened to a hardness of 90 to 97 HRB by spheroidizing annealing), which was tested at 1,030 ℃, and then processed to a hardness of 49HRC by rapid cooling and tempering. JIS No. 3 impact te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com