Microwave continuous freeze-drying system

A technology of freeze-drying and microwave, which is applied in the direction of drying, drying machine, progressive drying machine, etc., can solve the problems of high cost, high utilization rate of vacuum water catcher, long freeze-drying cycle, etc., and achieve high utilization rate, The effect of eliminating the breakdown phenomenon of microwave vacuum electric field and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

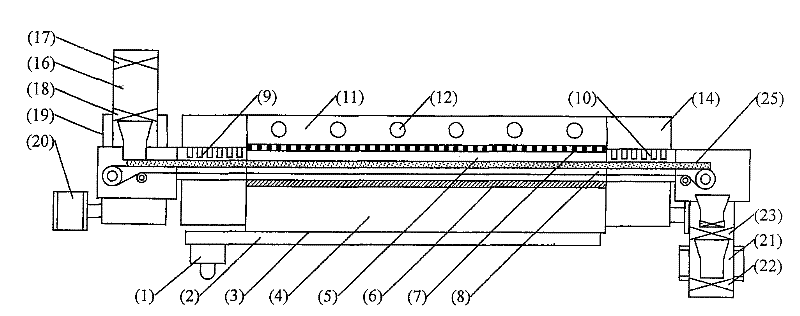

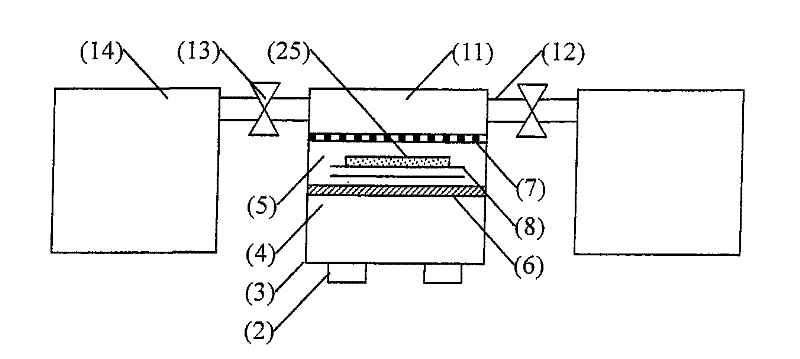

[0047] A microwave continuous freeze-drying system, comprising a microwave vacuum freeze-drying device, a vacuum water catcher, a vacuum feeding device, and a vacuum discharging device, wherein the microwave vacuum freeze-drying device includes a microwave generator 1, a microwave antenna 2, an atmospheric pressure microwave Cavity 4, vacuum microwave cavity 5, vacuum partition 6, porous air-permeable microwave shielding plate 7, low-loss conveyor belt 8, front-end vacuum microwave suppressor 9, rear-end vacuum microwave suppressor 10, characterized in that: freeze-dried in microwave vacuum The device is provided with a composite freeze-drying chamber 3 composed of an atmospheric microwave chamber 4 and a vacuum microwave chamber 5, and is separated by a microwave-permeable vacuum partition 6 between the atmospheric pressure microwave chamber 4 and the vacuum microwave chamber 5. The vacuum microwave cavity 5 is connected to the steam channel 11 of the vacuum water catcher, and...

Embodiment 2

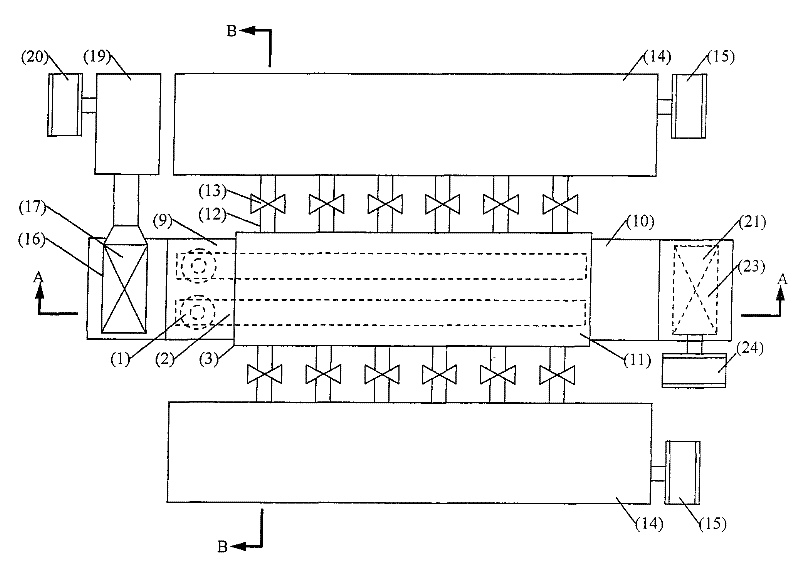

[0060] Such as figure 1 , 2 , 3 form a set of microwave continuous freeze-drying system. It consists of a vacuum feeding device for vertical feeding, a microwave vacuum freeze-drying device, a vacuum discharging device, and a vacuum water-catching device.

[0061] The specific design of each part of this embodiment is as follows:

[0062] 1. Microwave generator 1 adopts four 915MHz, 75kW microwave sources, with a total power of 300kW;

[0063] 2. Microwave energy is fed into the atmospheric pressure microwave cavity 4 by the microwave antenna 2;

[0064] 3. The distance between the atmospheric pressure microwave cavity 4 and the vacuum partition 6 is 500 mm to make the microwave field more uniform;

[0065] 4. The low-loss conveyor belt 8 is made of PTFE-coated glass fiber belt, which can avoid the falling of materials and is suitable for processing small or granular materials;

[0066] 5. The steam channel 11 of the vacuum water catcher is located above the vacuum microw...

Embodiment 3

[0081] Such as figure 1 , 2 , 3, but change the vacuum feeding device to such as Figure 7 , 8 shown. The system consists of a vacuum feeding device for horizontal feeding, a microwave vacuum freeze-drying device, a vacuum discharging device, and a vacuum water trapping device.

[0082] The specific design of each part of this embodiment is as follows:

[0083] 1. Microwave generator 1 uses two 2450MHz, 30kW microwave sources, with a total power of 60kW;

[0084] 2. The distance between the atmospheric pressure microwave cavity 4 and the vacuum partition 6 is 200mm to make the microwave field more uniform;

[0085] 3. The cold trap 14 of the vacuum water catching device has a water catching capacity greater than or equal to 120kg / h

[0086] 4. The horizontal feeding vacuum chamber is adopted, which can conveniently input large bulk materials;

[0087] 5. Others are the same as in Example 1.

[0088] The system formed in this embodiment can be used to process a cube-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com