Isolated high-power factor flyback type primary-side constant-current control device of LED driver

A technology of LED driver and high power factor, which is applied in the direction of lighting device, lamp circuit layout, light source, etc., can solve the problems of optocoupler aging, large number of circuit components, etc., and achieve circuit reliability, reduce electromagnetic interference, and reduce the number of components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

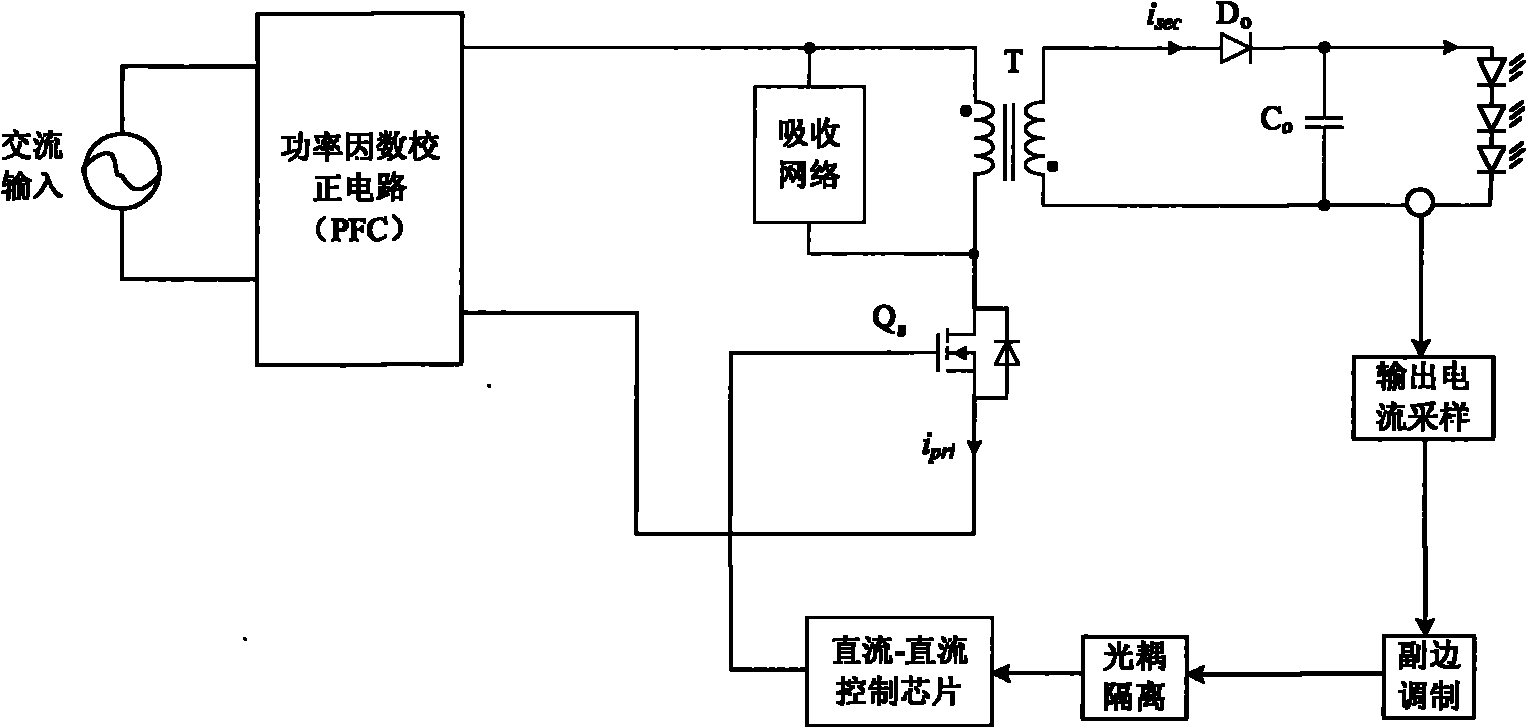

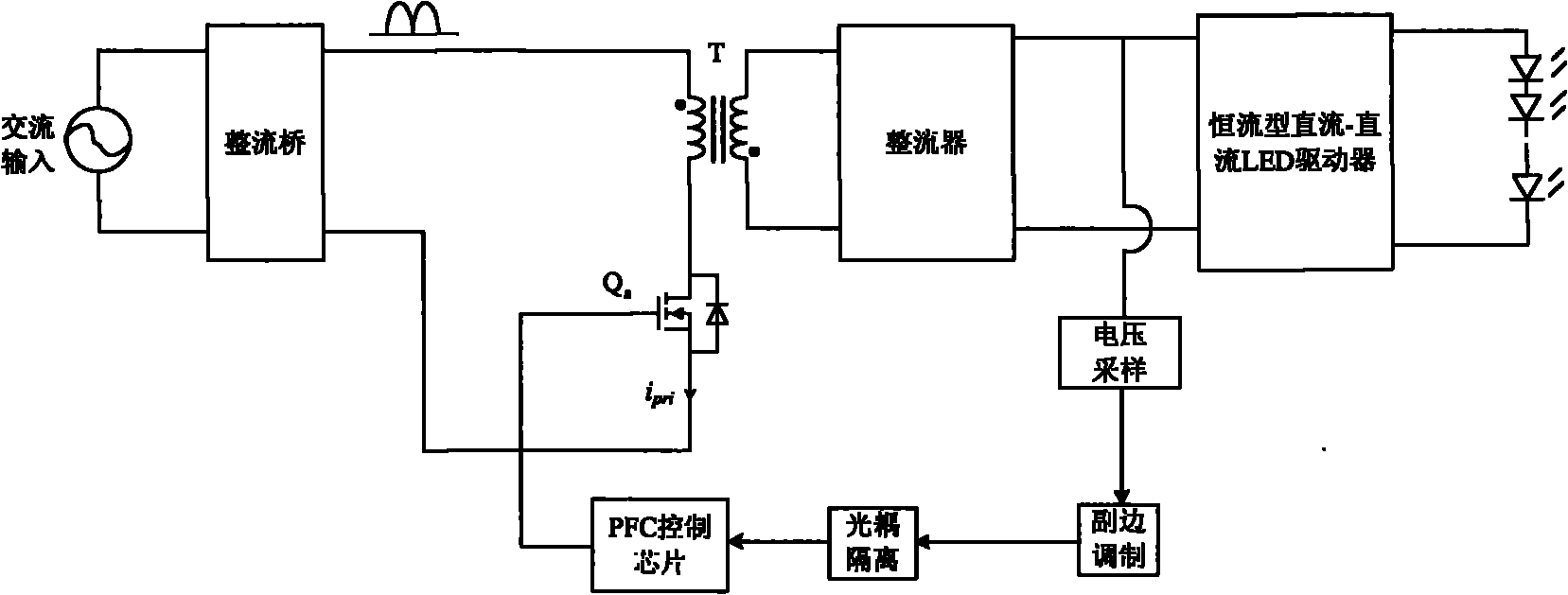

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

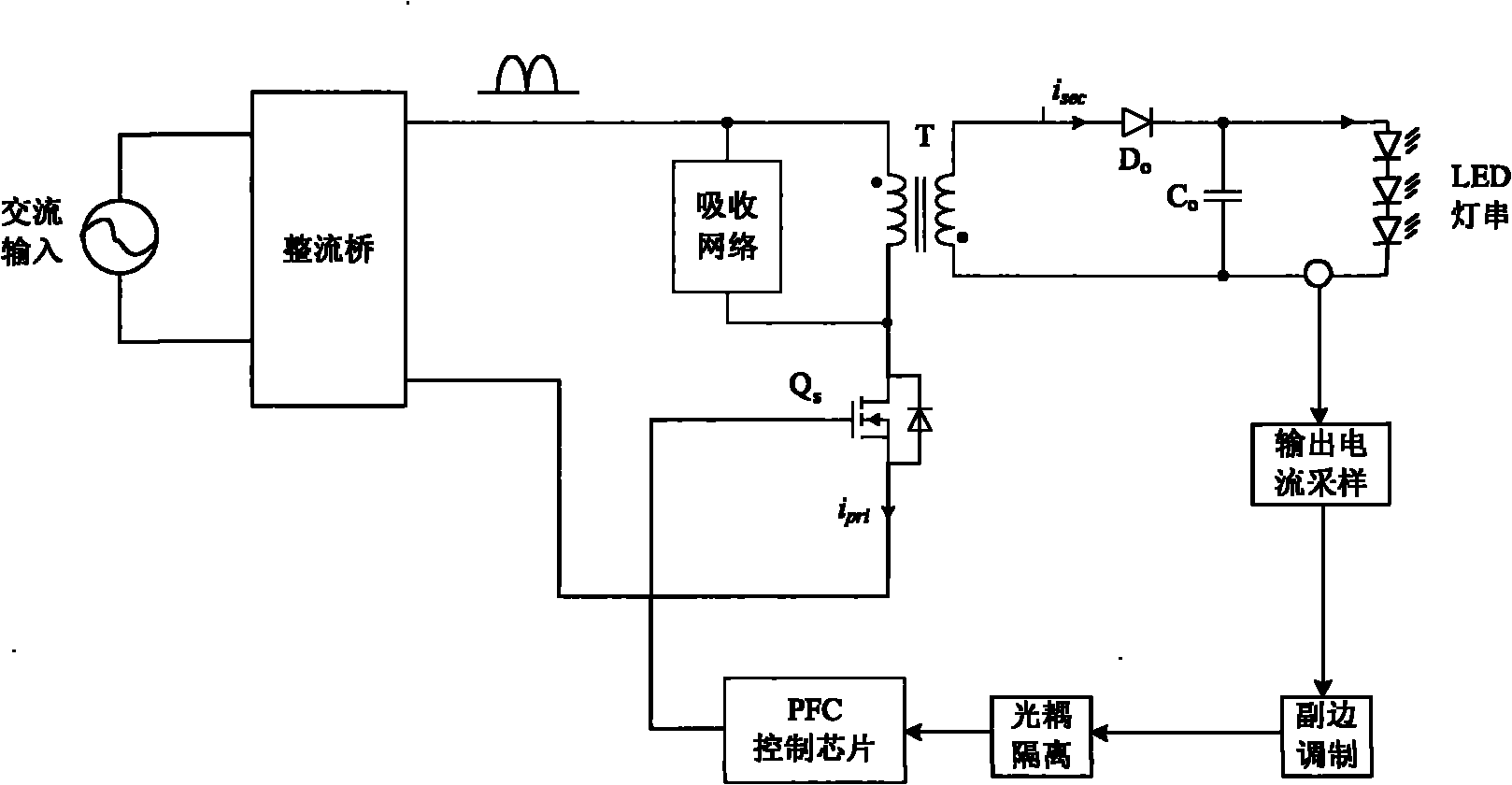

[0040] The content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0041] refer to Figure 4 The primary side constant current control device of the isolated high power factor flyback LED driver includes a peak sampling and holding module 21, a secondary side current simulation module 22, a half sine wave reference module 23, an average current loop 24, and a half sine wave generation module 25, A multiplication module 26 , a comparison module 27 , an inductor current zero-crossing detection module 28 , a driving pulse generation module 29 and a driving module 30 .

[0042] The application object of the present invention is the main circuit of the flyback LED driver, including the input rectifier bridge B 1 , input capacitance C in , transformer T, absorption network, primary side switch tube Q 1 , primary current sampling network, output rectifier (choose diode D 1 ) and the output capacitor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com