Oil tank with cellular metal foam structure for vehicle

A metal foam, motor vehicle technology, applied in the direction of vehicle components, the arrangement combined with the fuel supply of the internal combustion engine, the power unit, etc., to achieve the effects of reducing wear, reducing weight, and improving safety and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

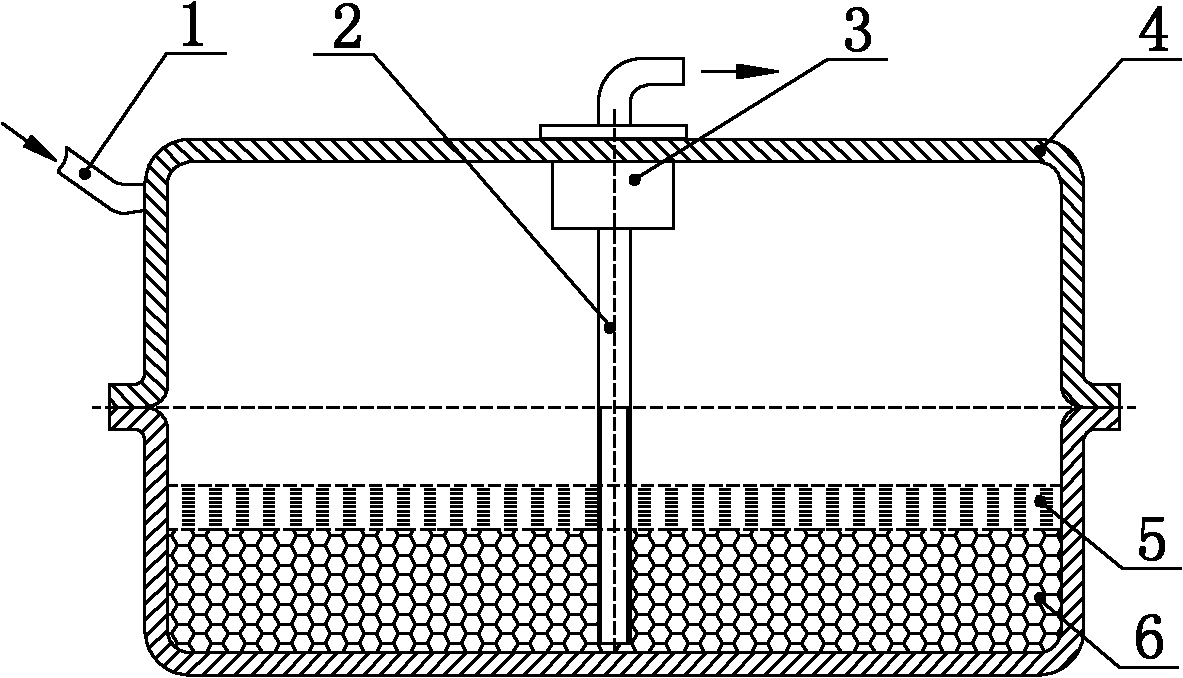

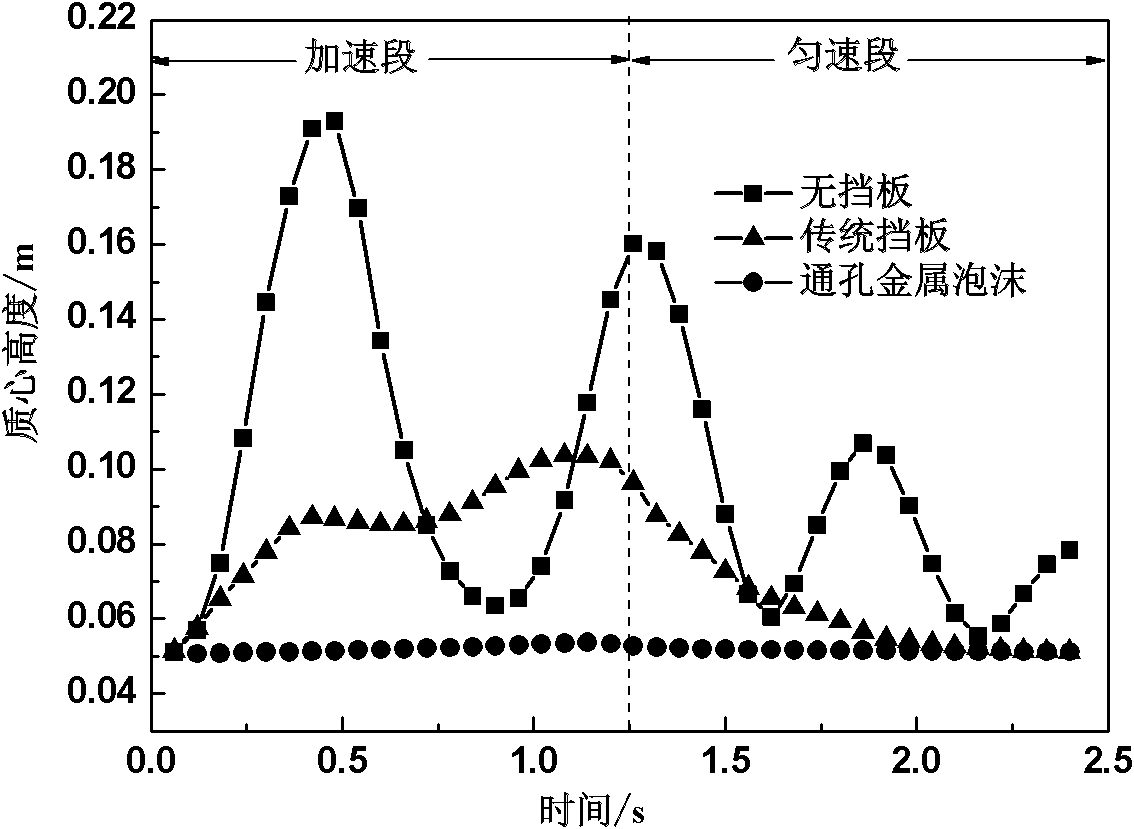

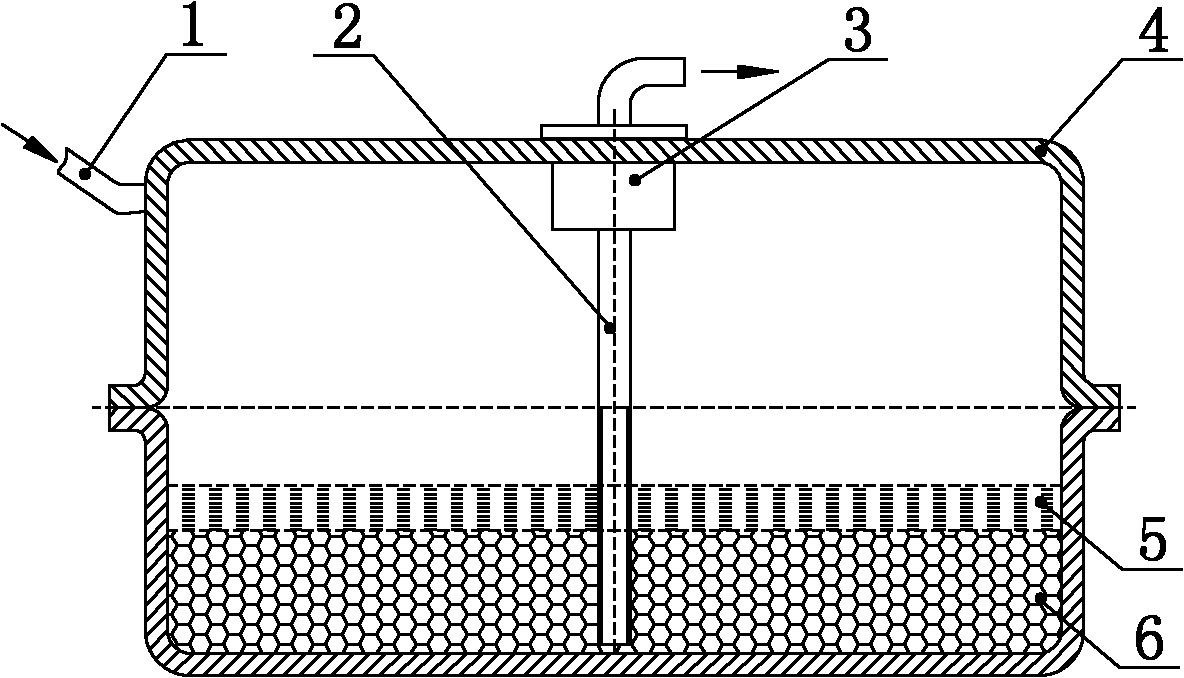

[0012] see figure 1 , the present invention includes a fuel tank body 4 with an oil inlet 1 and an oil suction pipe 2, a fuel pump 3 is arranged on the oil suction pipe 2 in the fuel tank body 4, and the lower end of the fuel tank body 4 is filled with metal foam made of through holes. The formed wave suppression and noise reduction device 6, and the oil suction pipe 2 is inserted into the wave suppression and noise reduction device. The wave suppression and noise reduction device 6 is to select the specification and size of filling according to different vehicle fuel tank volumes, shapes and operating conditions. Considering that when the fuel is less than half the volume of the fuel tank, the fluctuation of the oil increases sharply, and when the volume of the fuel is 1 / 3 of the volume of the fuel tank, the fluctuation reaches the maximum, and the filling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com