Chemical fibres capable of quickly cooling in wind and textile containing same

A chemical fiber and textile technology, applied in the field of chemical fiber and textiles containing the fiber, can solve the problems of high cost, poor softness, and loss of metal fibers, and achieve the effects of easy industrial production, low manufacturing cost, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of chemical fiber of the present invention that cools rapidly when exposed to wind, comprises conventional chemical fibers and nano units accounting for 0.1 to 4% by weight of the total weight, for example, nano units account for 2% of the total weight of chemical fibers, and the nano units of the present invention The unit includes microparticles of 300-8000 nanometers, and the microparticles mainly include Zn or Al or Ca or Na or P or La, or their mixtures. Generally, the above-mentioned microparticles of the present invention can be any one or several of them mixtures, or mixtures of them in any proportion. In this embodiment, the chemical fiber of the present invention, in addition to the conventional chemical fiber, contains about 2-4% by weight of the total weight of microparticles of 300-2000 nanometers. The microparticles include 30-60% by weight of Zn, 10-20% by weight of Al, and 20-60% by weight of a mixture of Ca, Na, P and La, wherein Ca, Na, P and La...

Embodiment 2

[0042] The difference between this embodiment and the above-mentioned embodiments is that the chemical fiber of the present invention includes microparticles of 2000-5000 nanometers accounting for about 1-2% by weight of the total weight. The microparticles include 45-60% by weight of Zn, 15-20% by weight of Al, and 20-40% by weight of a mixture of Ca, Na, P and La, wherein Ca, Na, P and La can be any Proportional mix.

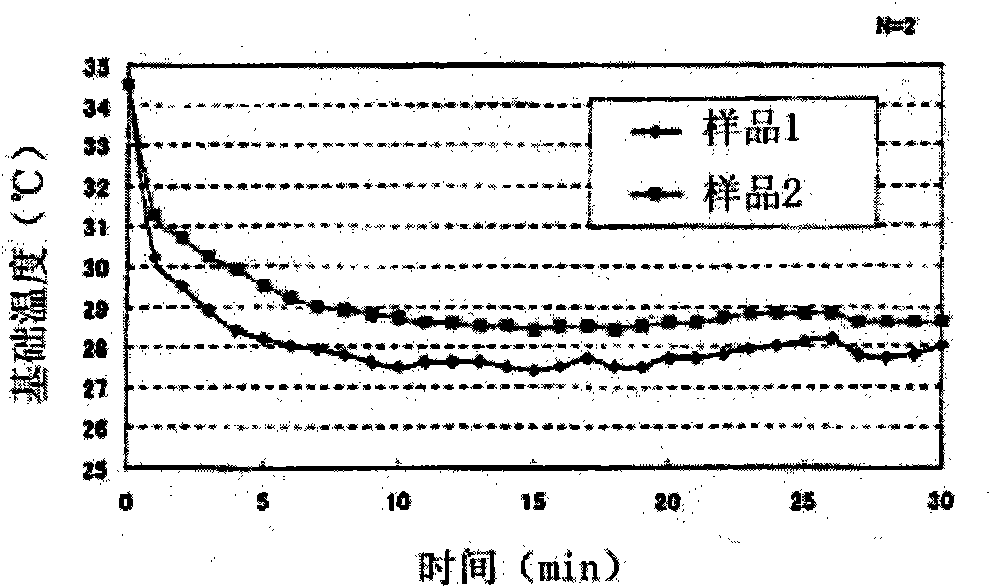

[0043] The cooling effect of the chemical fibers containing nano units in this embodiment can be quickly cooled by wind, see the following detection test:

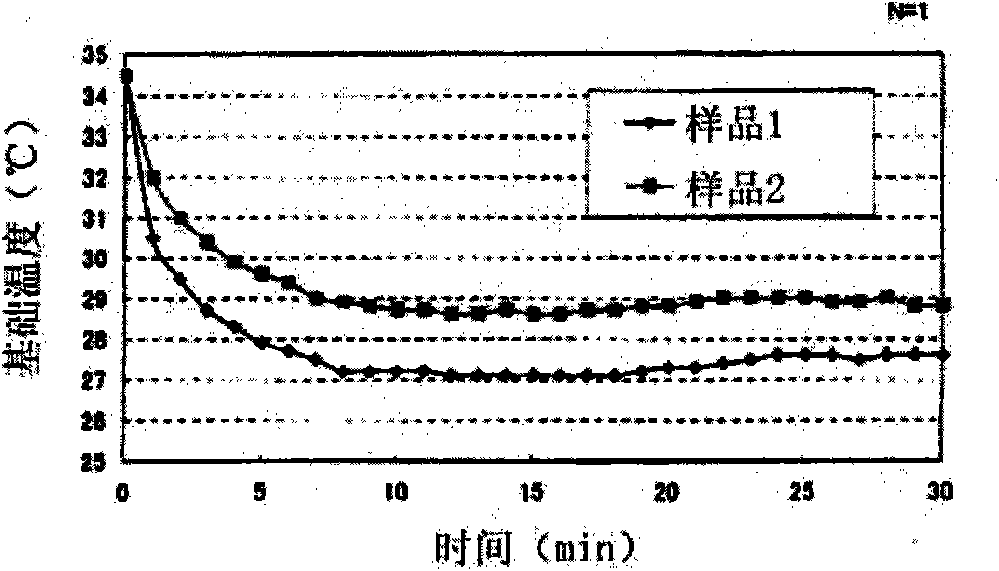

[0044] Test item 2: Water absorption and heat absorption test (second time, N=2):

[0045] Table 2 (N=2)

[0046] time (min)

Sample 1(°C)

Sample 2(°C)

[0047] 0

34.5

34.5

5

28.2

29.5

10

27.5

28.7

15

27.4

28.4

20

27.7

28.6

25

28.1

28.8

30

28.0

28.6

...

Embodiment 3

[0051] The difference between this embodiment and the above embodiments is that the chemical fiber of the present invention includes microparticles of 5000-8000 nanometers accounting for about 0.1-1% by weight of the total weight. The microparticles include 30-45% by weight of Si, 10-15% by weight of Al, and 40-60% by weight of a mixture of Ca, Na, P and La, wherein Ca, Na, P and La can be any Proportional mix.

[0052] The cooling effect of the chemical fibers containing nano units in this embodiment can be quickly cooled by wind, see the following detection test:

[0053] Test item 3: heating / cold contact feeling;

[0054] Detection method and detection results: as shown in the table below

[0055] This is to certify that the test results of the samples to be tested in the laboratory are as follows, Table 3

[0056]

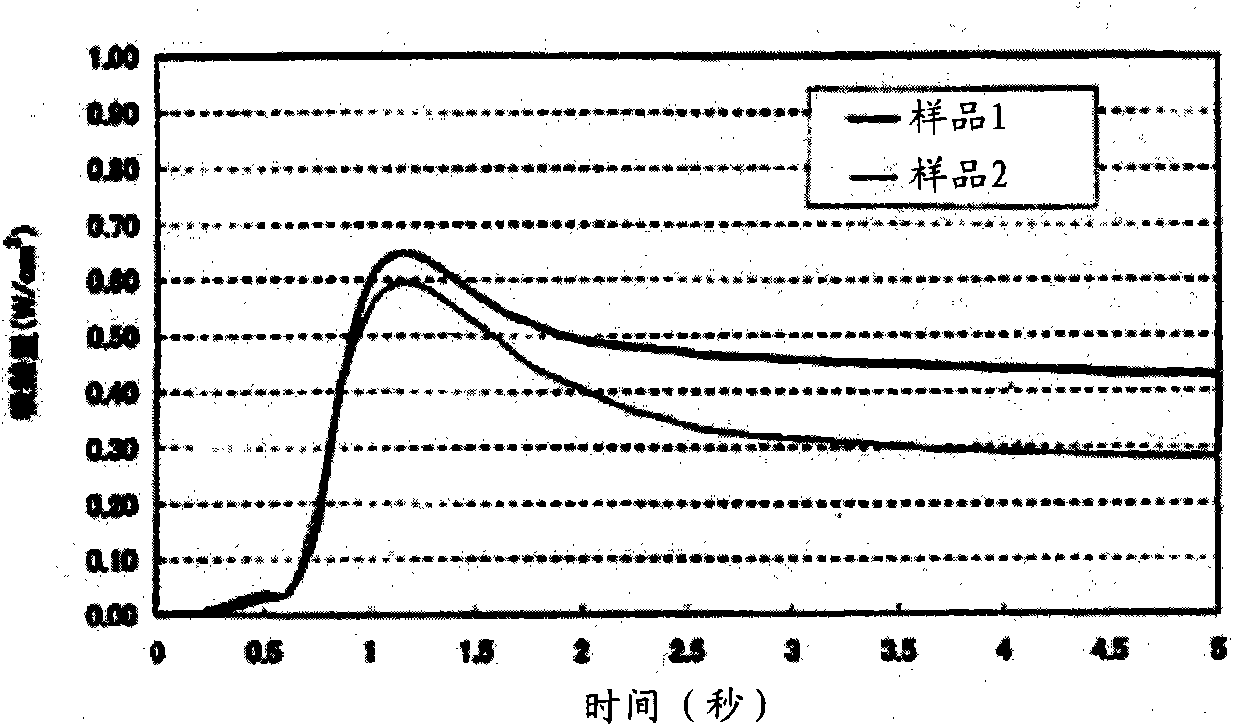

[0057] The relation curve of the endothermic heat that this embodiment detects changes with time sees appendix image 3 shown;

[0058] Through the test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com