Vortex cold vacuum aircraft engine

An aero-engine and scroll technology, which is applied to machines/engines, mechanical equipment, gas turbine devices, etc., can solve the problems of lack of independent intellectual property rights in key technologies, late start of aero-engines, and difficulty in improving, etc. The effect of many and low working resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

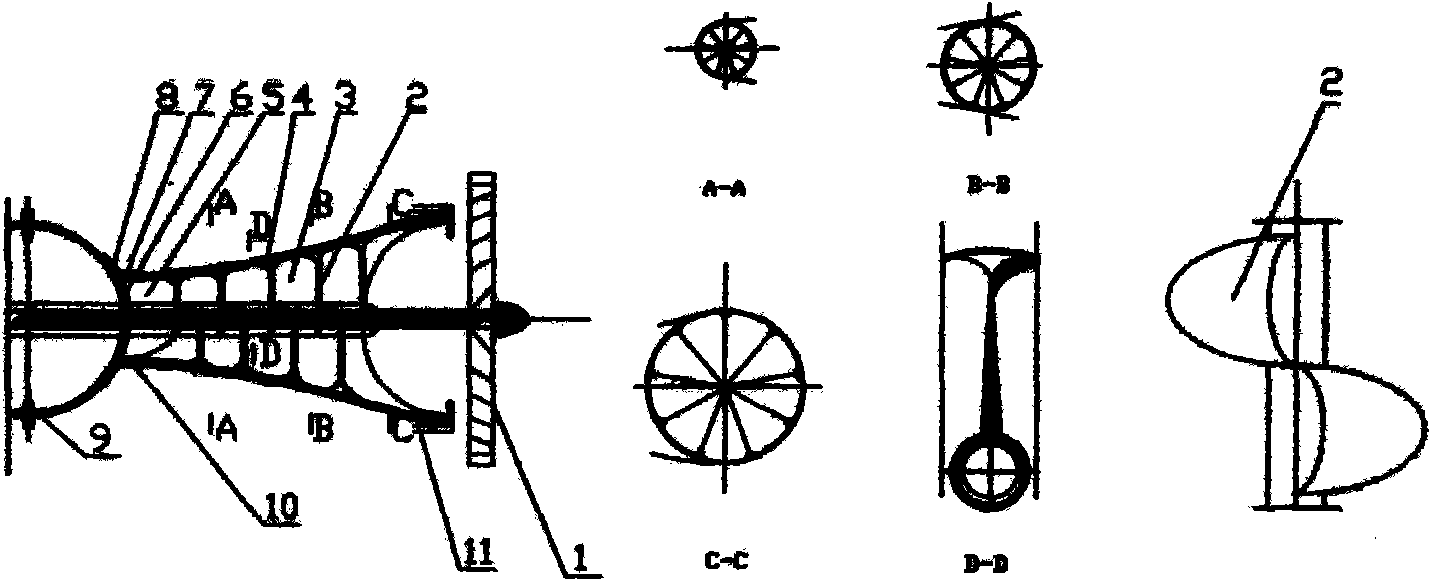

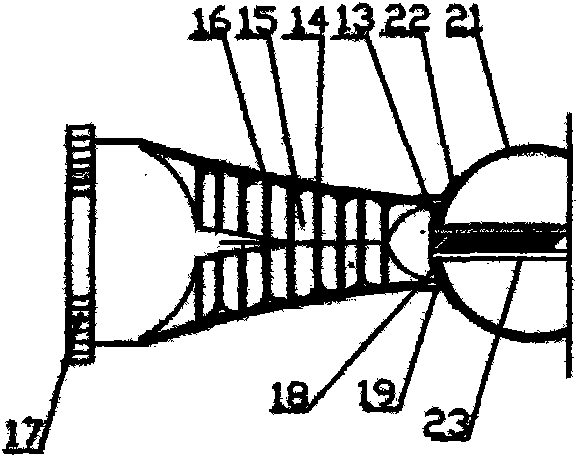

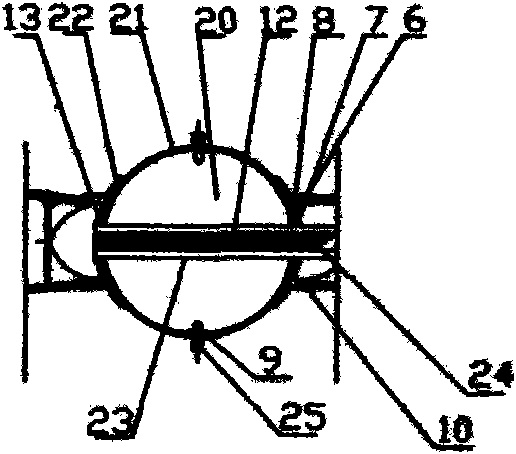

[0030] The technical solutions of the present invention will be further described in conjunction with the accompanying drawings of the above embodiments.

[0031] The working mechanism of the vortex cold vacuum aero-engine is composed of three main working processes of "(A)-(C)-(B)".

[0032] Such as figure 1 Shown is (A) schematic diagram of the working process of the vortex cold vacuum aeroengine of the present invention, transmitted by (B) machine (belonging to the active rotational force) 16, through the main transmission shaft 12, and the sheath 24 to form a three-dimensional vortex vane Road 3, the spindle rod 23 drives the (A) machine barrel 4 to rotate, so that the (A) blade road produces continuous, long-distance, long-term circumferential tangential force, radial centripetal force, and axial suction force on the gas fluid, The turbofan 1 is driven to inhale fuel and air, wherein the fuel injection controller 9 injects fuel to mix with the inhaled air, and performs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com