Annular magnetic hub for powder metallurgy and preparation method thereof

A powder metallurgy, ring-shaped technology, applied in the manufacture of stator/rotor body, magnetic circuit characterized by magnetic materials, etc., can solve the problems of low work efficiency, large volume, easy to heat, etc., to improve production efficiency, product quality High precision and improved magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

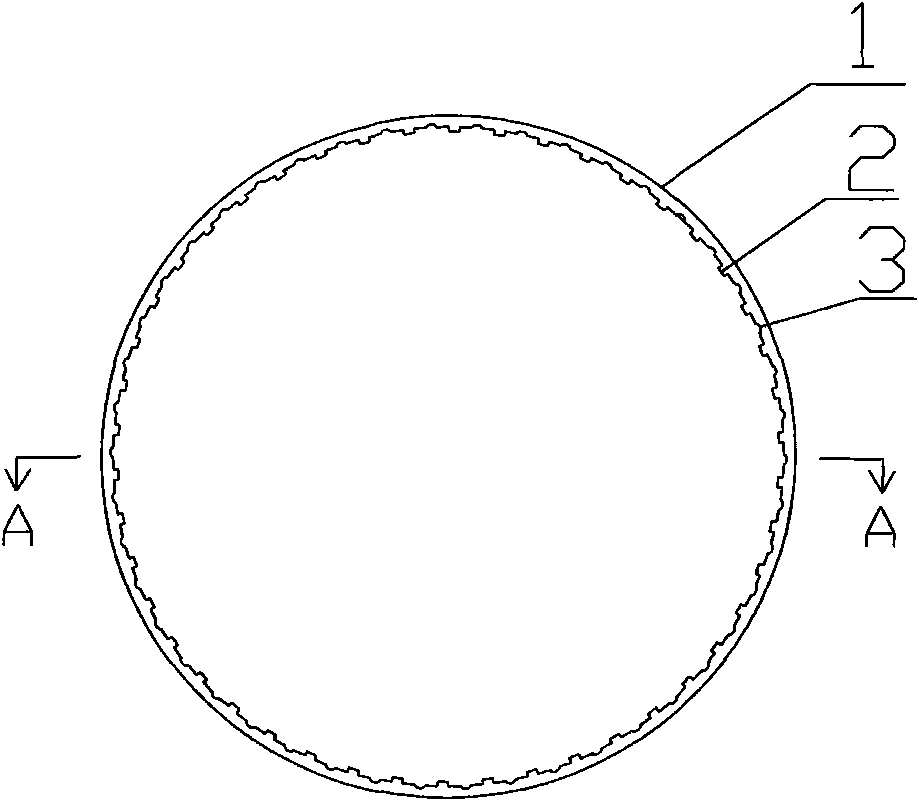

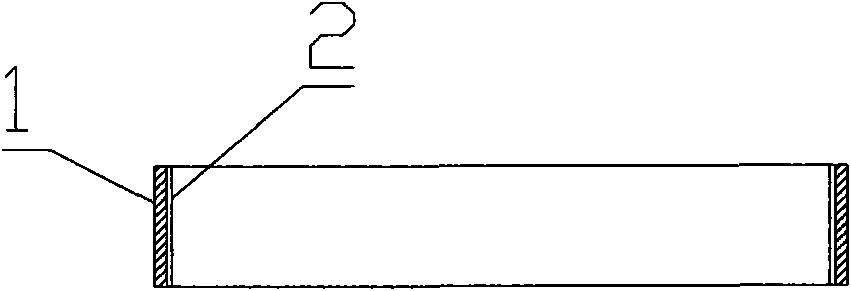

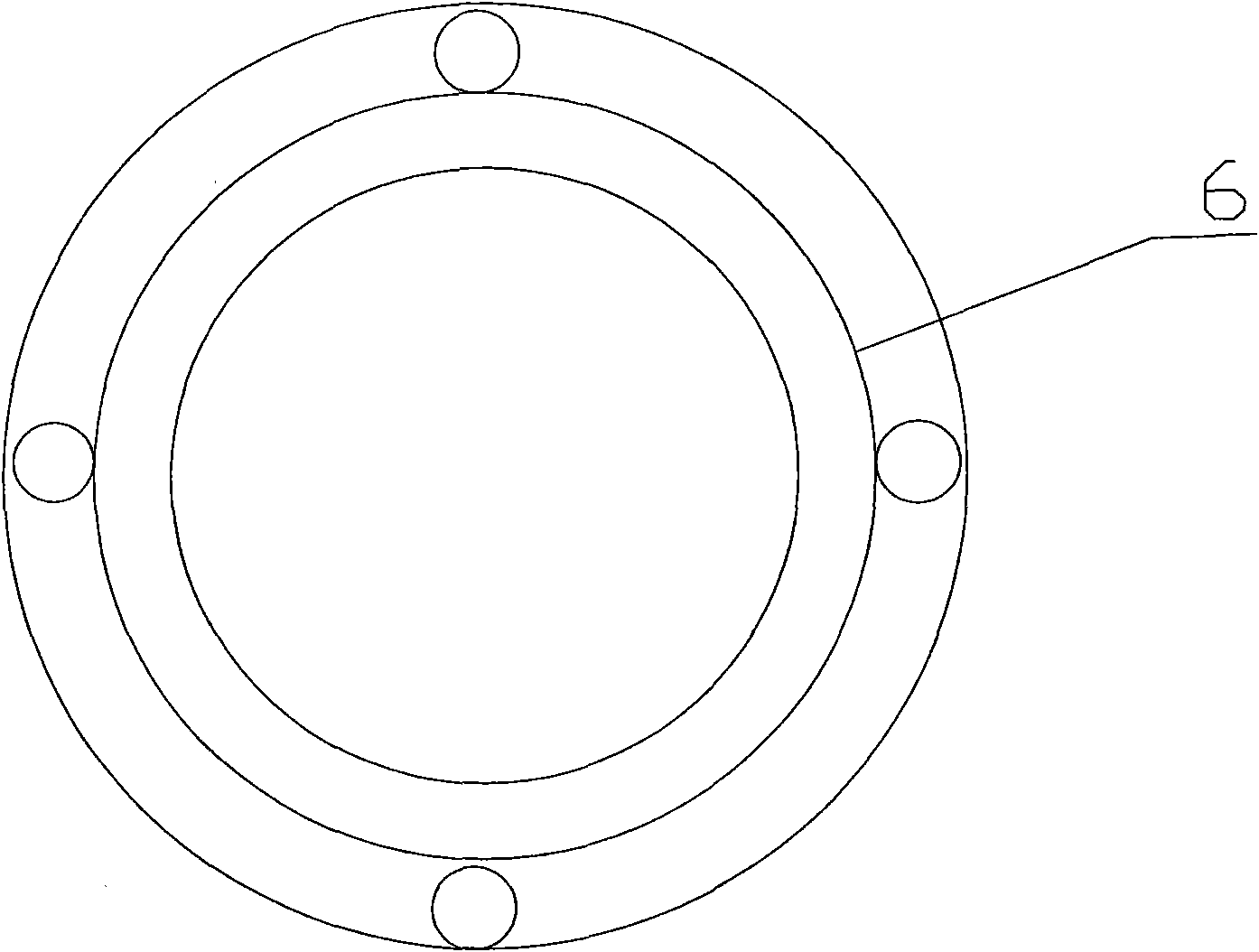

[0035] Refer to attached figure 1 , 2 Preparation of the present invention. figure 1 , 2 An embodiment of a powder metallurgy circular magnetic hub prepared by the present invention is given. The powder metallurgy annular magnetic hub is characterized in that it is composed of a ring 1, the inner diameter of the ring 1 is 204.75mm, the outer diameter of the ring 1 is 213mm, and the height of the ring 1 is 24mm. There are rectangular magnetic teeth 2 with a rectangular cross section on the inner wall of the inner wall, the width of the rectangular magnetic teeth 2 is 3 mm, the distance between adjacent rectangular magnetic teeth 2 is 10.8 mm, and there are 46 rectangular magnetic teeth 2 in total. The inner wall of the ring 1 between the teeth 2 is provided with a groove 3 with a depth of 0.2 mm and a width of 2 mm; the composition of the ring 1 and its rectangular magnetic teeth 2 is as follows: the weight of pure iron powder is 100 Part, the weight of lubricant is 0.8 p...

Embodiment 2

[0048] The shape and manufacturing process steps of the powder metallurgy magnetic hub are the same as those in Example 1. However, improvements have been made in the ratio and where there is a limited interval: the composition of the ring 1 and its rectangular magnetic teeth 2 is as follows: the weight of pure iron powder is 100 parts, and the weight of lubricant is 1 part.

[0049] The depth of the groove 3 provided on the inner wall of the ring 1 between adjacent magnetic teeth 2 is changed to 0.1mm, and the width is changed to 3mm. After mixing, molding, pressing, sintering, cooling, and finishing, it is processed into products. In the mixing step, use pure iron powder as raw material, weigh 100 parts by weight, add 1 part of lubricant, and use a double-cone mixer for 50 minutes of mixing. In the sintering step, the sintering temperature is 1133°C, sintering at high temperature for 60 minutes, and cooling with the furnace. During this sintering process, the added lubrica...

Embodiment 3

[0054] The shape and preparation process of the powder metallurgy magnetic hub are the same as in Example 1, but improvements have been made in the ratio and where there are interval limits: the composition of the ring 1 and its rectangular magnetic teeth 2 is: pure iron powder The weight is 100 parts, and the weight of the lubricant is 0.5 parts.

[0055] The depth of the groove 3 provided on the inner wall of the ring 1 between adjacent magnetic teeth 2 is changed to 0.15mm, and the width is changed to 3mm. After mixing, molding, pressing, sintering, cooling, and finishing, it is processed into products. In the mixing step, pure iron powder is used as a raw material, weighing 100 parts, plus 0.5 part of lubricant, using a double-cone mixer, and mixing for 40 minutes. In the sintering step, the sintering temperature is 1127°C, sintering at high temperature for 40 minutes, and cooling with the furnace. During this sintering process, the added lubricant evaporates.

[0056] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com