Coiling type reverse osmosis membrane element with even water distribution

A reverse osmosis membrane and uniform water distribution technology, which is applied in the fields of semipermeable membrane separation, osmosis/dialysis water/sewage treatment, membrane technology, etc., can solve the problems of low production efficiency and poor operability, and achieve production operability Strong, reduce pollution speed, prolong the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

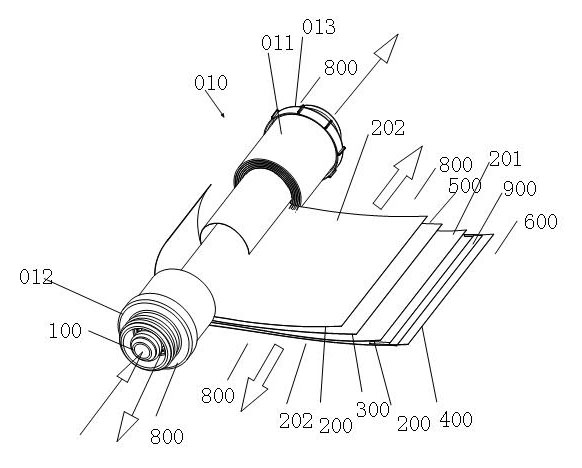

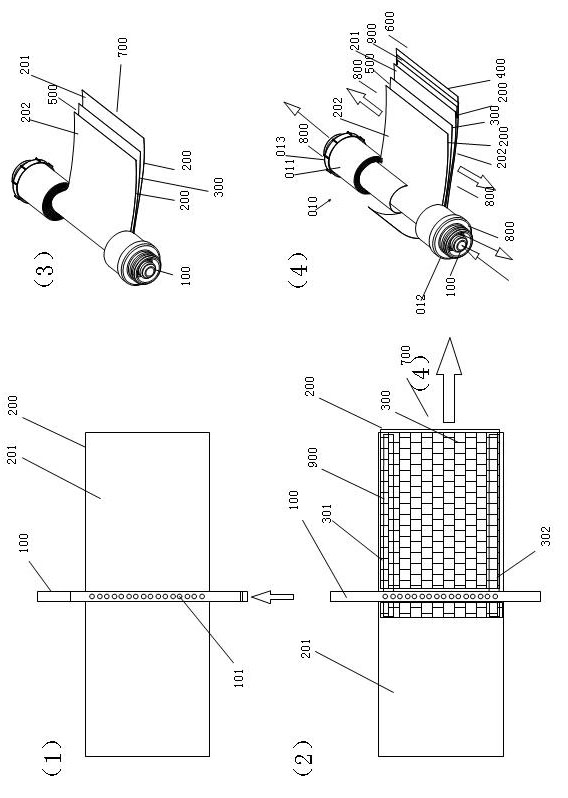

[0017] Such as figure 1 As shown, the roll-type reverse osmosis membrane element 010 with uniform water distribution of the present invention includes a central pipe 100 , a reverse osmosis membrane 200 , an inlet water diversion net 300 and a pure water diversion net 400 .

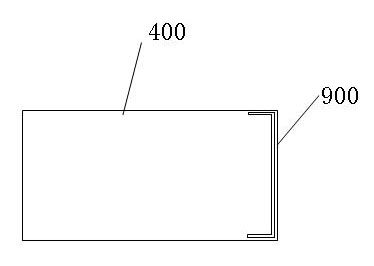

[0018] Among them, the reverse osmosis membrane 200 is first folded in half and then wound on the central tube 100 so that the reverse osmosis membrane 200 forms a water inlet channel 500 between the front 201 interlayers, and the reverse osmosis 202 interlayers form a water production channel 600, and the water inlet diversion net 300 Then it is located in the water inlet channel 500 , and the pure water diversion net 400 is located in the produced water channel 600 .

[0019] The reverse osmosis membrane 200 can be folded in two ways, one of which is as Figure 5 As shown, the front side 201 of the reverse osmosis membrane 200 is located outside, and the reverse side of the reverse osmosis membrane 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com