Phosphate with dihydroxyl structure and preparation method thereof

A technology of bishydroxyl and phosphoric acid ester, which is applied in the field of phosphoric acid ester and its preparation, can solve the problems that affect the performance of polyurethane materials and products, and have a large impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

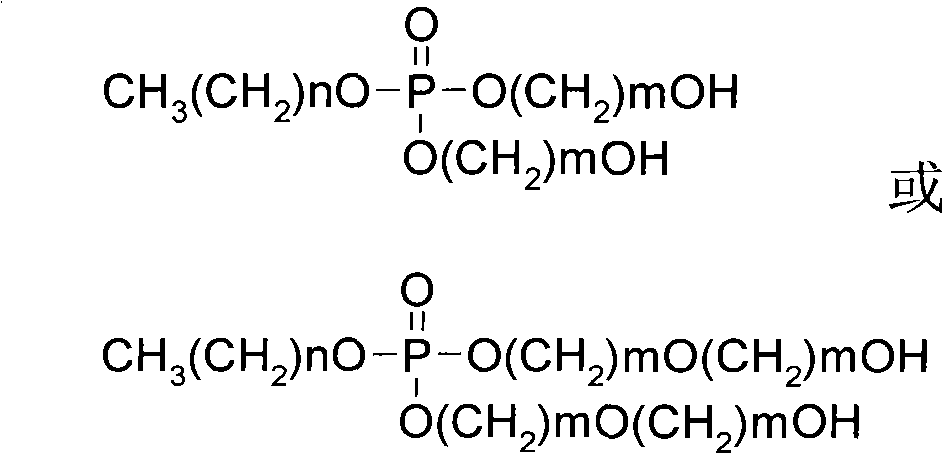

Method used

Image

Examples

Embodiment 1

[0037] Synthesis of 1-n-butoxydiethanoloxy phosphate

[0038] 1. Product description

[0039] Product name: 1-n-butoxydiethanoloxy phosphate

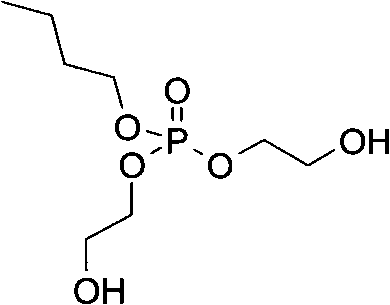

[0040] Molecular Structure:

[0041]

[0042] Molecular weight: 242.11

[0043] Quality Index:

[0044] Appearance: colorless or light yellow transparent liquid

[0045] Acid value: (mgKOH / g) ≤0.02

[0046] Chromaticity: (APHA) ≤5

[0047] Boiling range: ℃ 235-240

[0048] Ignition point: ℃ 267

[0049] Lightning: °C 238

[0050] Specific gravity: (20 / 25℃) 1.017-1.023

[0051] Moisture:% ≤0.05

[0052] Physical and chemical properties:

[0053] Colorless or light yellow transparent liquid; boiling point: 236℃; refractive index: n25=1.432-1.438; solubility in water at 20℃: 25.6%; specific gravity: (20 / 25℃): 1.032-1.043; soluble in alcohol, phosphorus and other solvents .

[0054] Uses: Reactive polyurethane resin flame retardant.

[0055] 2. Synthesis technology

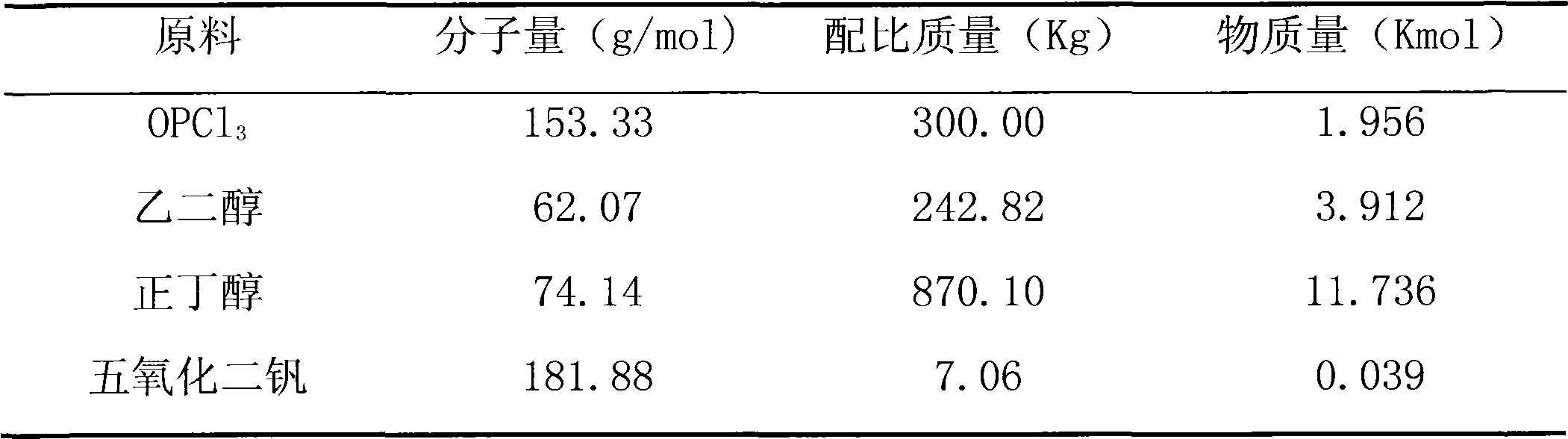

[0056] Raw material ratio

[0057]

[0058] 1) The first step of esterification reaction:

[0059]...

Embodiment 2

[0078] Synthesis of 1-n-butoxydipropanoloxy phosphate

[0079] 1. Product description

[0080] Product name: 1-n-butoxy dipropanol oxy phosphate

[0081] Molecular Structure:

[0082]

[0083] Molecular weight: 270.14

[0084] Quality Index:

[0085] Appearance: colorless or light yellow transparent liquid

[0086] Acid value: (mgKOH / g) ≤0.02

[0087] Chromaticity: (APHA) ≤5

[0088] Boiling range: ℃ 240-244

[0089] Ignition point: ℃ 400

[0090] Lightning: ℃ 378

[0091] Specific gravity: (20 / 25℃) 1.017-1.023

[0092] Moisture:% ≤0.05

[0093] Physical and chemical properties:

[0094] Colorless or light yellow transparent liquid; boiling point: 236℃; refractive index: n25=1.432-1.438; solubility in water at 20℃: 25.6%; specific gravity: (20 / 25℃): 1.032-1.043; soluble in alcohol, phosphorus and other solvents .

[0095] use:

[0096] Polyurethane resin flame retardant.

[0097] 2. Synthesis technology

[0098] Raw material ratio

[0099]

[0100] 1) The first step of esterification reaction:

[0101...

Embodiment 3

[0121] Synthesis of 1-n-Butoxy Diethylene Glycoloxy Phosphate

[0122] 1. Product description

[0123] Product name: 1-n-butoxy diethylene glycol oxy phosphate

[0124] Molecular Structure:

[0125]

[0126] Molecular weight: 330.11

[0127] Quality Index:

[0128] Appearance: colorless or light yellow transparent liquid

[0129] Acid value: (mgKOH / g) ≤0.02

[0130] Chroma: (APHA) ≤8

[0131] Boiling range: ℃ 255-260

[0132] Ignition point: ℃ 247

[0133] Lightning: °C 228

[0134] Specific gravity: (20 / 25℃) 1.019-1.026

[0135] Moisture:% ≤0.05

[0136] Physical and chemical properties:

[0137] Colorless or light yellow transparent liquid; boiling point: 236℃; refractive index: n25=1.448-1.455; solubility in water at 20℃: 48.6%; specific gravity: (20 / 25℃): 1.042-1.049, soluble in alcohol, phosphorus and other solvents .

[0138] use:

[0139] Reactive polyurethane resin flame retardant.

[0140] 2. Synthesis technology

[0141] Raw material ratio

[0142]

[0143] 1) The first step of esterificati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com