Production process for high-performance steel plate thermal treatment unit

A production process and high-performance technology, applied in the direction of heat treatment furnace, heat treatment equipment, process efficiency improvement, etc., can solve the problems of difficulty in opening and leveling, straightening, and inability to produce coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

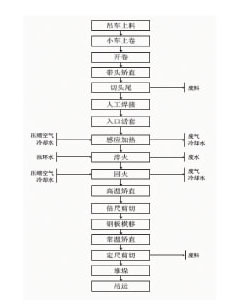

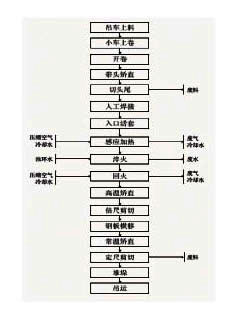

Image

Examples

Embodiment Construction

[0066] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0067] Such as figure 1 Shown, the high-performance steel plate heat treatment unit production technology of the present invention is characterized in that comprising the following steps:

[0068] 1) The hot-rolled steel coil is hoisted by the workshop crane to the entrance coil storage saddle. After the steel coil is transported by the coiling trolley into the uncoiler reel, the coil expands to hold the steel coil, and the coiling trolley descends and exits.

[0069] 2) The reel of the uncoiler rotates, the uncoiler is adjusted in the vertical and horizontal directions, and the steel plate is fed into the pinch roller,

[0070] 3) During the uncoiling process, the pinch roller is pressed against the outer surface of the steel coil to prevent the outer layer of the steel coil from being loosened. After the steel plate is threaded into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com