Free curved surface micro-lens array device for photo-etching multi-pole illumination

A technology of microlens array and curved surface lens, which is applied in the field of lithography, can solve the problems of increasing system complexity, light beam entering the gap, reducing energy utilization rate, etc., and achieves the effect of wide application range, high energy utilization rate and small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

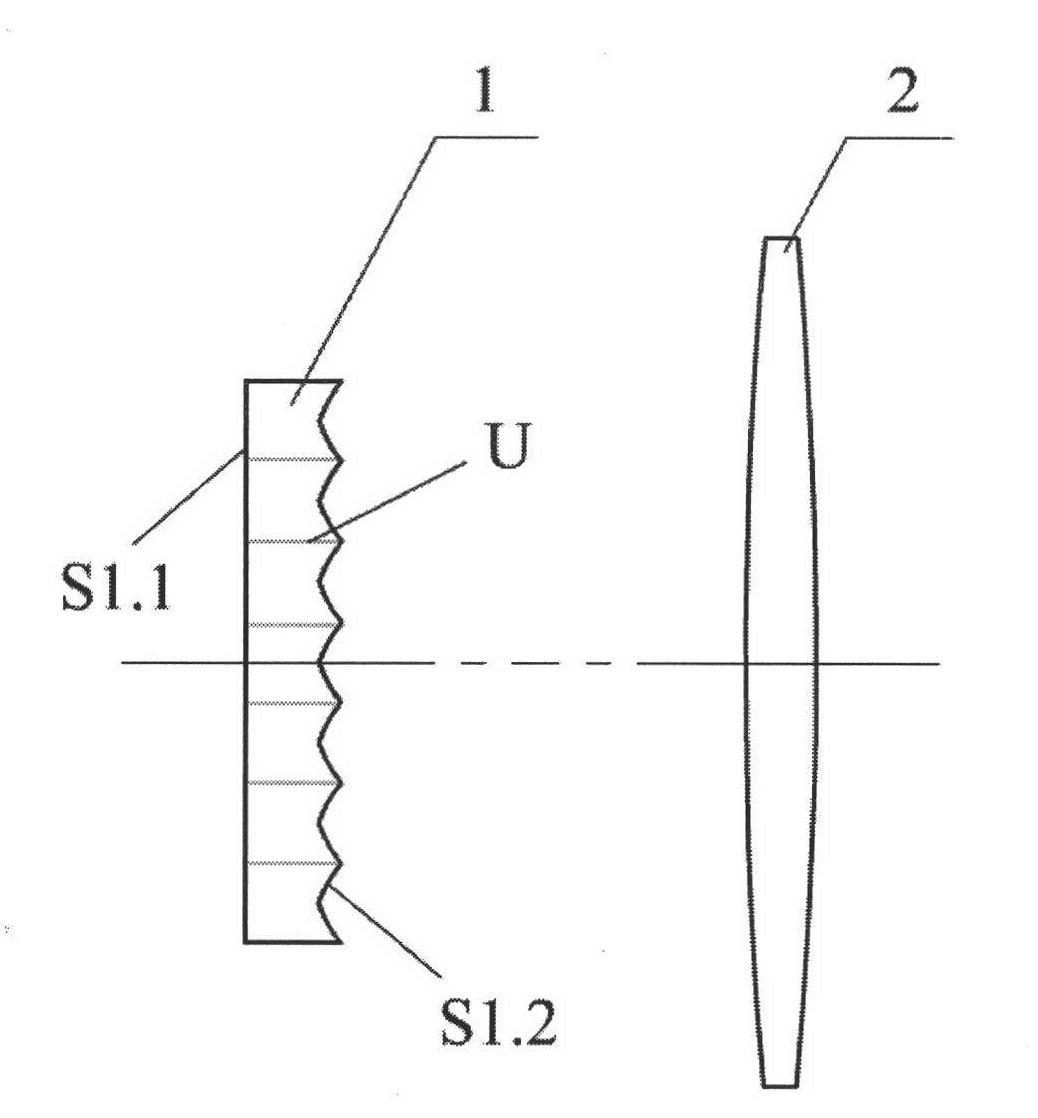

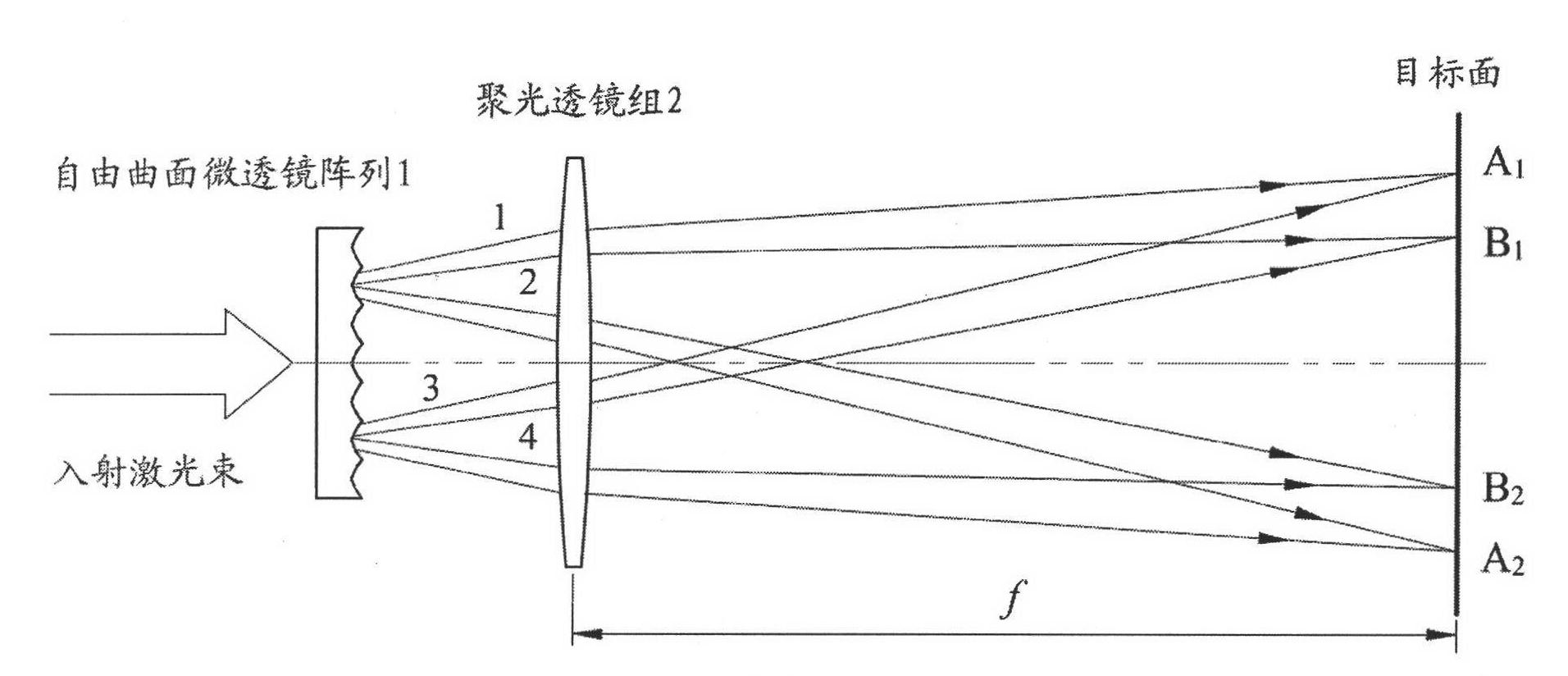

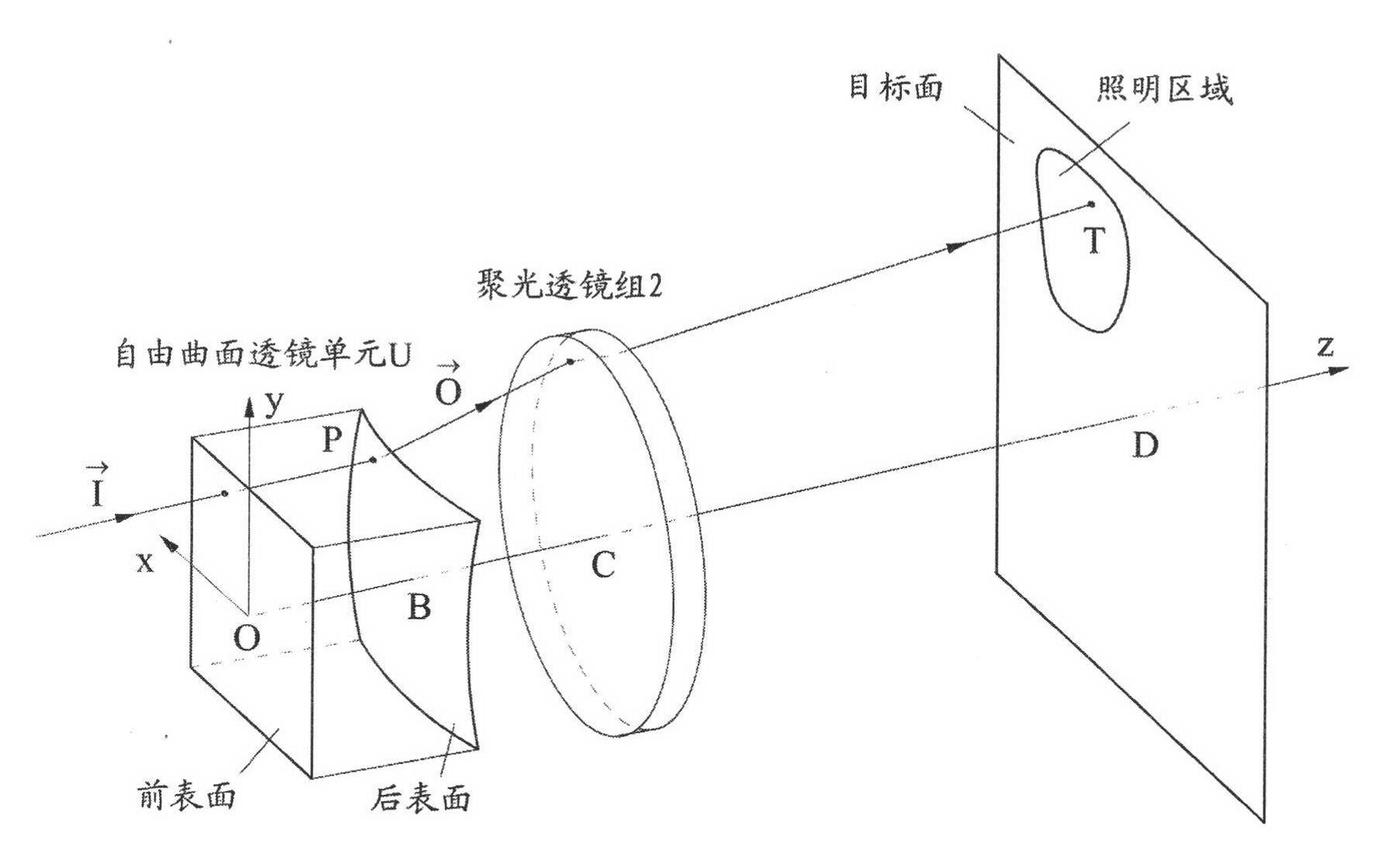

[0077] The dipole illumination mode is realized on the target surface by adopting the free-form surface micro-lens array device for lithography multipole illumination proposed by the present invention.

[0078] The cross-sectional shape of the free-form surface lens unit U perpendicular to the optical axis of the free-form surface micro-lens array for dipole illumination is rectangular, the front surface S2.1 of the free-form surface lens unit U is a plane, and the rear surface S2.2 is composed of the first The free-form surface S2.2.1 and the second free-form surface S2.2.2 are formed. exist Figure 4 middle, Figure 4 (a) is a cross-sectional view of the free-form surface lens unit U for realizing dipole illumination, Figure 4 (b) is the dipole illumination spot on the target surface. The first free-form surface S2.2.1 corresponds to the dipole illumination spot I on the target surface, and the second free-form surface S2.2.2 corresponds to the dipole illumination spot I...

Embodiment 2

[0096] The quadrupole illumination mode is realized on the target surface by using the free-form surface microlens array device for lithography multipole illumination proposed by the present invention.

[0097] The free-form surface lens unit U of the free-form surface microlens array of quadrupole illumination has a rectangular cross-sectional shape perpendicular to the optical axis, the front surface S3.1 of the free-form surface lens unit U is a plane, and the rear surface S3.2 is formed by the first free-form surface S3. .2.1, the second free-form surface S3.2.2, the third free-form surface S3.2.3, the fourth free-form surface S3.2.4, the first plane S3.2.5, the second plane S3.2.6, the third plane S3.2.7 and the fourth Plane S3.2.8 constitutes. exist Figure 9 middle, Figure 9 (a) is a sectional view of the free-form surface lens unit U for realizing quadrupole illumination, Figure 9 (b) is the quadrupole illumination spot on the target surface. The first free-form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com