Device and method for measuring flexural stiffness of textile fabric

A technology of bending stiffness and measuring device, which is applied in the direction of testing material strength by applying a stable bending force, can solve the problems of large measurement error, poor practicability, and tradition, and achieve high repeatability, accurate measurement, and exquisite structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

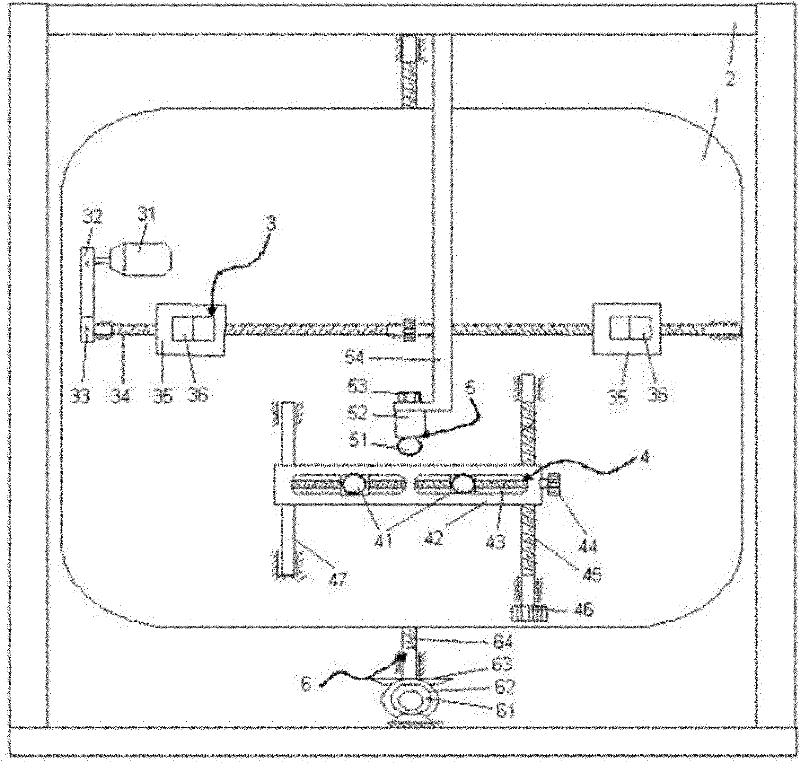

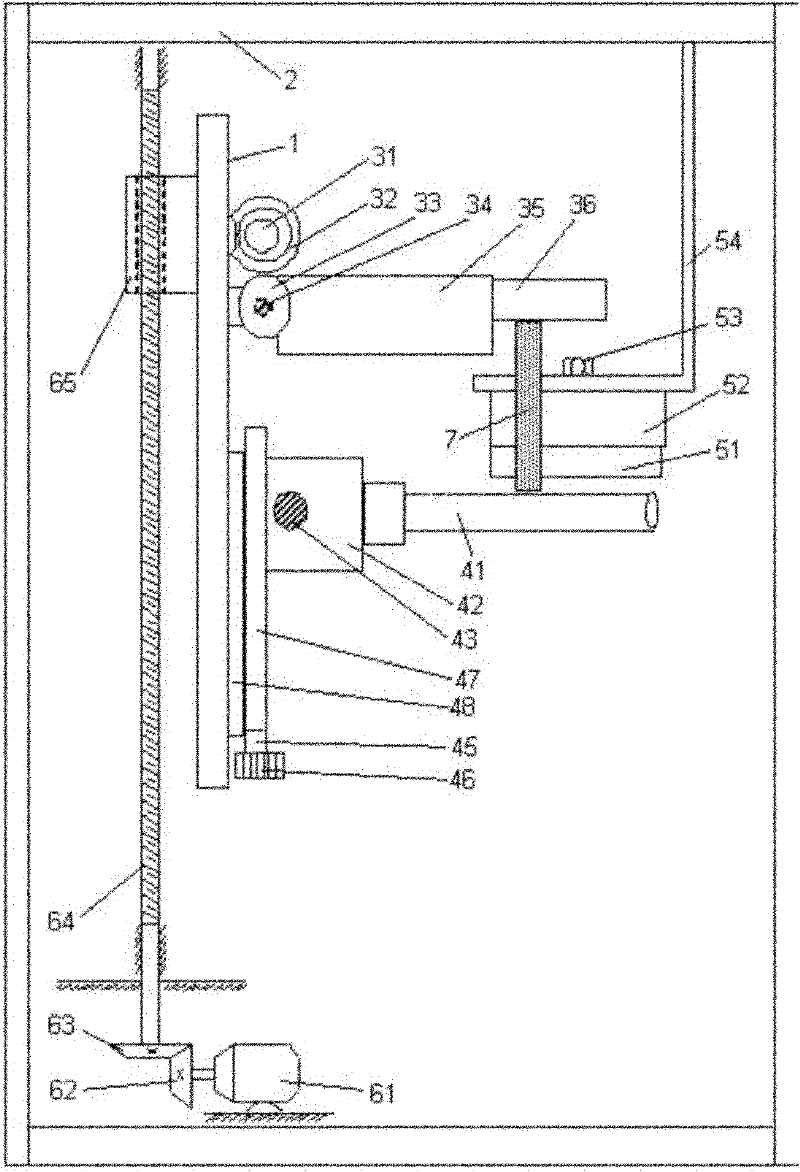

[0037] Embodiment 1: Measurement of woven fabric bending stiffness

[0038] ①Choose a pair of moving pins 41 with circular cross-section, rubber-coated surface, and 2 mm outer diameter, and adjust the center distance between the stainless steel rod of the left moving pin and the stainless steel rod of the right moving pin to 6 mm; select the cross-section as a circle Shape, the surface is covered with rubber, fixed needle 51 with an outer diameter of 2mm and a force sensor 52 with a measuring range of 0.1kg and an accuracy of 0.01%; m 2 , the warp yarn arrangement density and the weft yarn arrangement density are 228 / 10cm and 214 / 10cm respectively, the warp yarn count is 68, and the weft yarn count is also 68; On the head 36, the other end passes through the top of a pair of moving needles 41 and the bottom of the fixed needle 51, and then clamped on the other chuck 36 of the clamping mechanism 3, so that the fabric 7 above the left moving needle and the right moving needle ...

Embodiment 2

[0039] Embodiment 2: Measurement of bending stiffness of knitted fabrics

[0040] ① Select a pair of moving pins 41 with an elliptical cross-section of stainless steel rods, rubber-coated surfaces, and an outer diameter of 3 mm, and adjust the center distance between the stainless steel rod of the left moving pin and the stainless steel rod of the right moving pin to 10 mm; the selected cross-section is elliptical shape, the surface is covered with rubber, the fixed needle 51 with an outer diameter of 3mm and the force sensor 52 with a measuring range of 0.1kg and an accuracy of 0.01%; On one chuck 36 of the clamping mechanism 3, the other end passes through the top of a pair of moving needles 41 and the bottom of the fixed needle 51, and then clamped on the other chuck 36 of the clamping mechanism 3; ③Start the second motor 61 to drive the second worm gear 62 and the second gear 63 rotate, thereby rotating the screw mandrel 64, and drive the drive block 65 to drive the bottom...

Embodiment 3

[0041] Example 3: Measurement of bending stiffness of nonwoven fabrics

[0042] ① Select a pair of moving needles 41 with a plum petal-shaped cross section of stainless steel rods, coated polyester film on the surface, and an outer diameter of 10 mm, and adjust the center distance between the stainless steel rod of the left moving needle and the stainless steel rod of the right moving needle to 28 mm; The cross-section is plum petal-shaped, the surface is coated with polyester film, the fixed needle 51 with an outer diameter of 8 mm, and the force sensor 52 with a measuring range of 1 kg and an accuracy of 0.01%; ② Select a non-woven fabric for testing, clamp one end of the non-woven On one chuck 36 of the clamping mechanism 3, the other end passes above a pair of moving needles 41 and below the fixed needle 51, and then clamps on the other chuck 36 of the clamping mechanism 3; ③Start the second motor 61 drives the second worm wheel 62 and the second gear 63 to rotate, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com