Nafion/sulfonated SiO2 molecular sieve composite proton exchange membrane and preparation method thereof

A technology of proton exchange membrane and molecular sieve, applied in the field of proton exchange membrane, can solve problems such as reducing proton conductivity, and achieve the effects of simple method, short preparation period and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

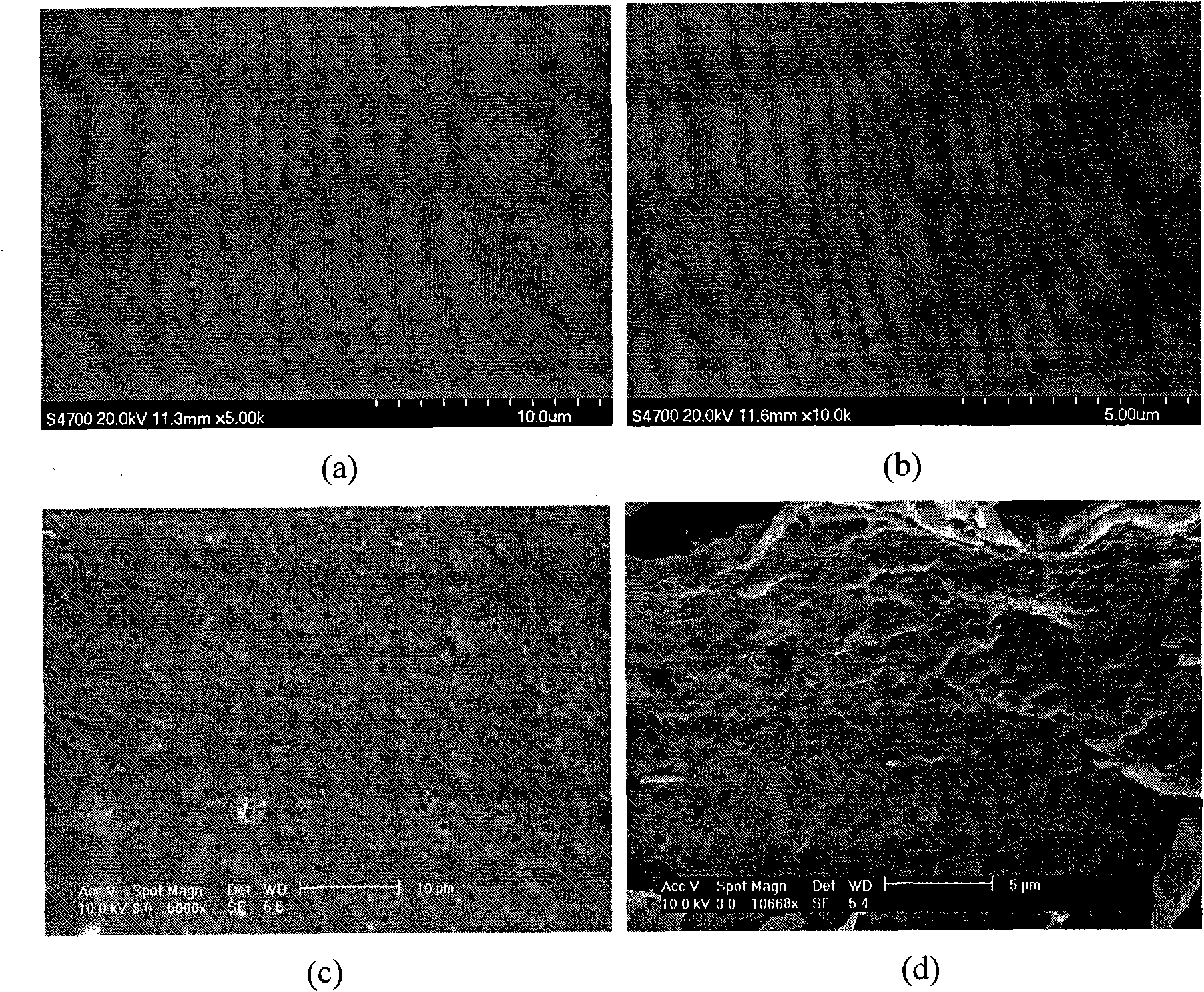

Image

Examples

Embodiment 1

[0026] Take by weighing 50g 5wt% Nafion alcohol solution and 47.5g DMF and mix and carry out vacuum distillation, remove the alcohols of low boiling point, obtain Nafion-DMF mixed solution; 2 Molecular sieves were added to 15ml of 0.5M sulfuric acid solution, stirred for 30min, and then the whole solution was dried in an oven at 100°C for 24h to obtain sulfonated SiO 2 Molecular sieve powder;

[0027] According to sulfonated SiO 2 The content of molecular sieve is 1%, weigh 0.0063g sulfonated SiO 2 Pour the molecular sieve into the Erlenmeyer flask, then pour 6g DMF, ultrasonically disperse for 30 minutes, then add 15g of the above-mentioned Nafion-DMF mixed solution into the Erlenmeyer flask, continue ultrasonically dispersing for 30 minutes, and obtain a milky white cast film after standing for defoaming liquid; the casting solution is cast into a clean and flat glass petri dish, heat-treated in an oven at 60°C for 2 hours, at 80°C for 2 hours, and at 100°C for 12 hours to...

Embodiment 2

[0029] Take by weighing 50g 5wt% Nafion alcohol solution and 47.5g DMF and mix and carry out vacuum distillation, remove the alcohols of low boiling point, obtain Nafion-DMF mixed solution; 2 Molecular sieves were added to 10ml of 0.5M sulfuric acid solution, stirred for 45min, and then the whole solution was dried in an oven at 100°C for 24h to obtain sulfonated SiO 2 Molecular sieve powder;

[0030] According to sulfonated SiO 2 The content of molecular sieve is 3%, weigh 0.0189g sulfonated SiO 2 Pour the molecular sieve into the Erlenmeyer flask, then pour 6g of DMF, ultrasonically disperse for 45 minutes, then add 15g of the above-mentioned Nafion-DMF mixed solution into the Erlenmeyer flask, continue ultrasonically dispersing for 30 minutes, and obtain a milky white cast film after standing for defoaming liquid; the casting solution is cast into a clean and flat glass petri dish, heat-treated in an oven at 60°C for 2 hours, at 80°C for 2 hours, and at 100°C for 12 hours...

Embodiment 3

[0032] Take by weighing 50g 5wt% Nafon alcohol solution and 45g DMF and mix and carry out vacuum distillation, remove the alcohols of low boiling point, obtain Nafion-DMF mixed solution; 2 Molecular sieves were added to 15ml of 0.5M sulfuric acid solution, stirred for 60min, and then the whole solution was dried in an oven at 100°C for 24h to obtain sulfonated SiO 2 Molecular sieve powder;

[0033] According to sulfonated SiO 2 The content of molecular sieve is 5%, weigh 0.0316g sulfonated SiO 2 Pour the molecular sieve into the Erlenmeyer flask, then pour 4g DMF, ultrasonically disperse for 30 minutes, then add 12g of the above-mentioned Nafion-DMF mixed solution into the Erlenmeyer flask, continue ultrasonically dispersing for 45 minutes, and obtain a milky white cast film after standing for defoaming liquid; the casting solution is cast into a clean and flat glass petri dish, heat-treated in an oven at 60°C for 2 hours, at 80°C for 2 hours, and at 100°C for 12 hours to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com