Impact gas-liquid distributor

A gas-liquid distributor and impact-type technology, applied in chemical instruments and methods, boiling devices, chemical/physical/physicochemical processes, etc., can solve problems such as complex structure, low mass transfer efficiency, and only distribution, and achieve equipment structure Simple, high mass transfer efficiency and low pressure drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

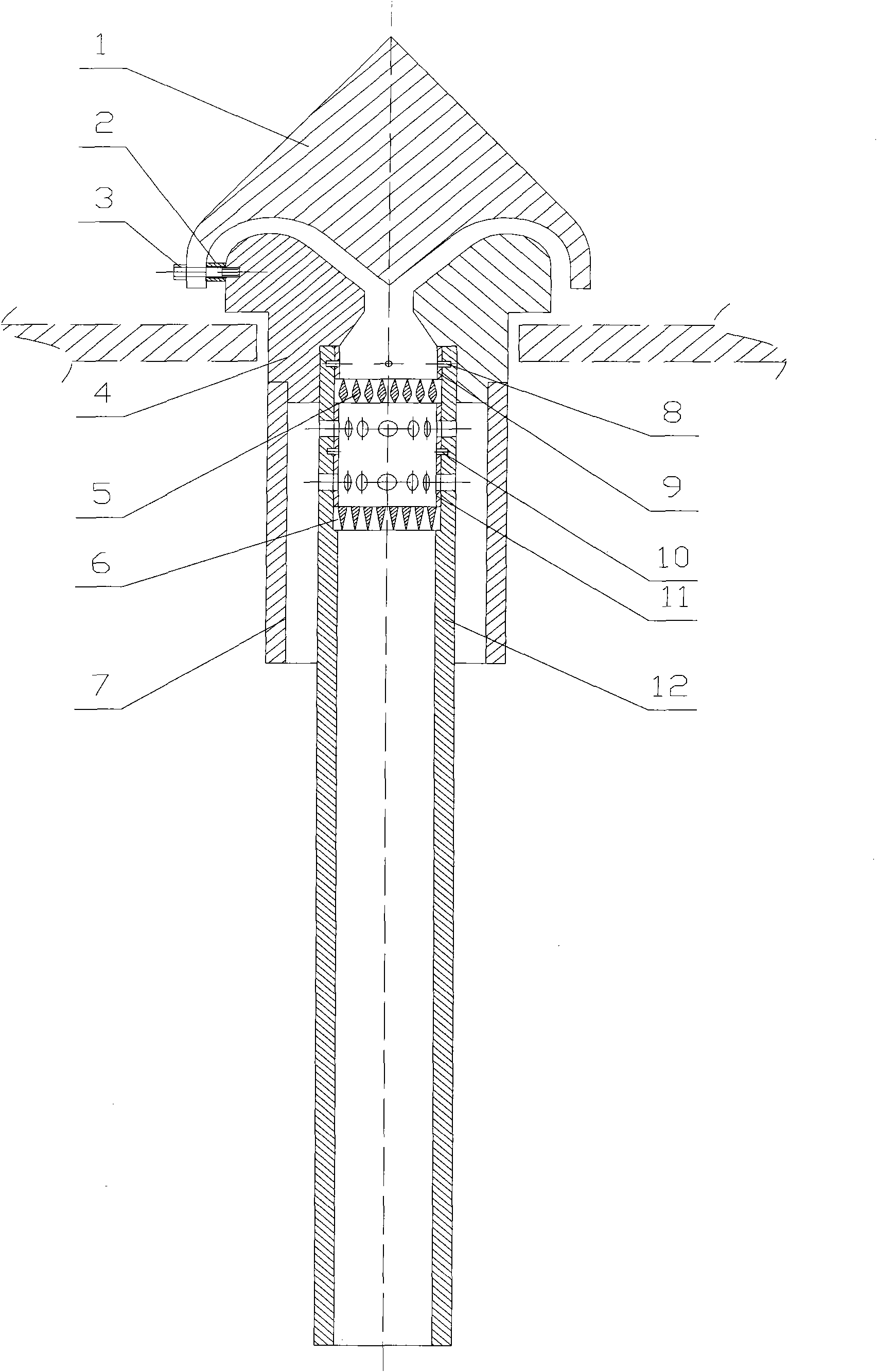

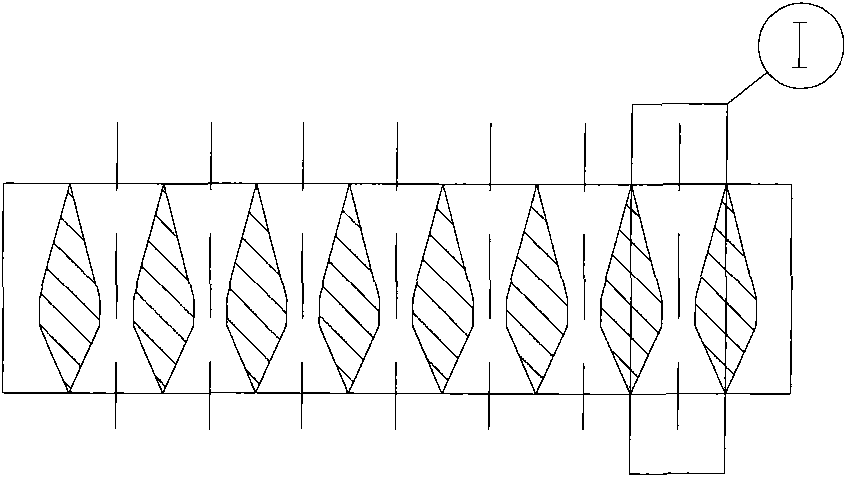

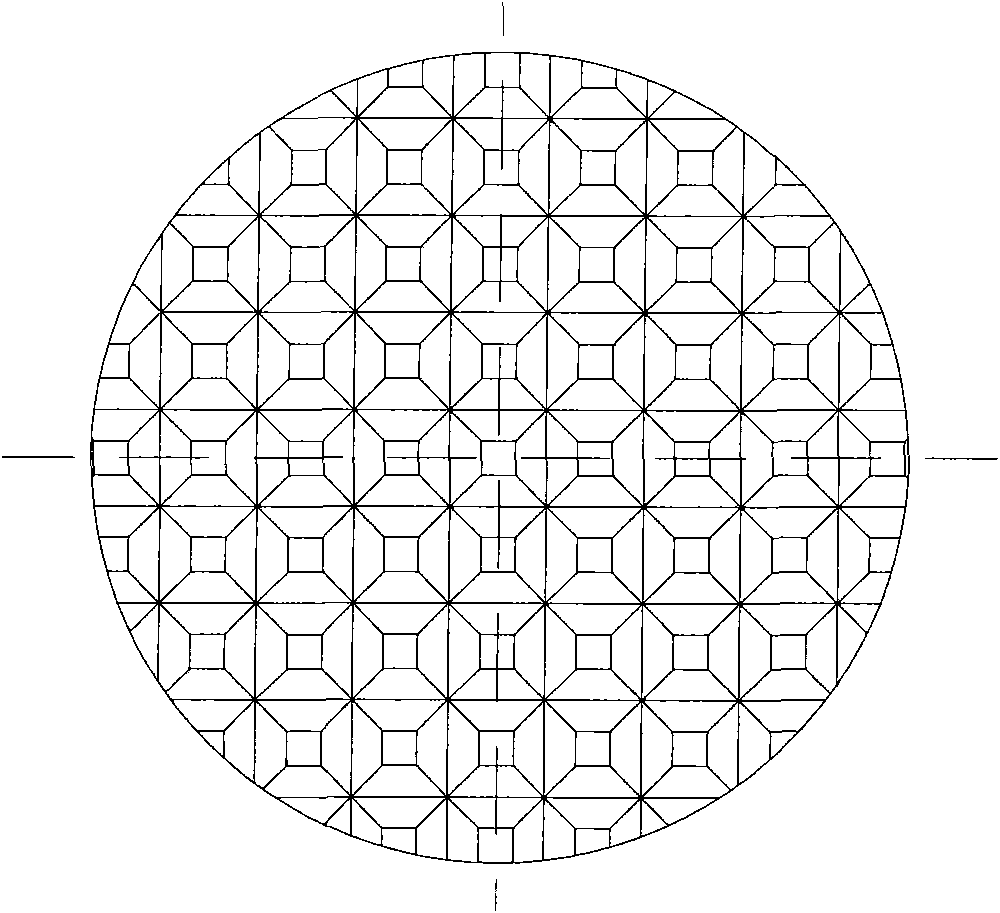

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings. Such as figure 1 , 2 , Shown in 3, impact type gas-liquid distributor of the present invention is made of ejection disc 6, mixing disc 5, connecting body 4, rain cap 1, gas phase cofferdam 7, catheter 12, limit sleeve 2, fastening sleeve 9 , positioning sleeve 11, positioning pin 10, screw 8 and connecting rod 3 and other components.

[0019] The impact type gas-liquid distributor of the present invention is provided with a gas-phase cofferdam 7 and a catheter 12, and the length of the gas-phase cofferdam is 1 / 3 to 2 / 3 of the length of the catheter; the annular area between the gas-phase cofferdam and the catheter is It is 1 / 3 to 2 times of the cross-sectional area of the catheter, preferably 1 to 1.5 times. The annular area between the gas phase cofferdam and the liquid guide tube constitutes a gas phase channel, and the liquid guide tube extends under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com