Adjustable aerofoil and double-body aircraft aerofoil layout scheme thereof

A kind of airfoil and wing technology, applied in the aviation field, can solve the problems of limiting the flight speed of aircraft, long runways, and consuming too much fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

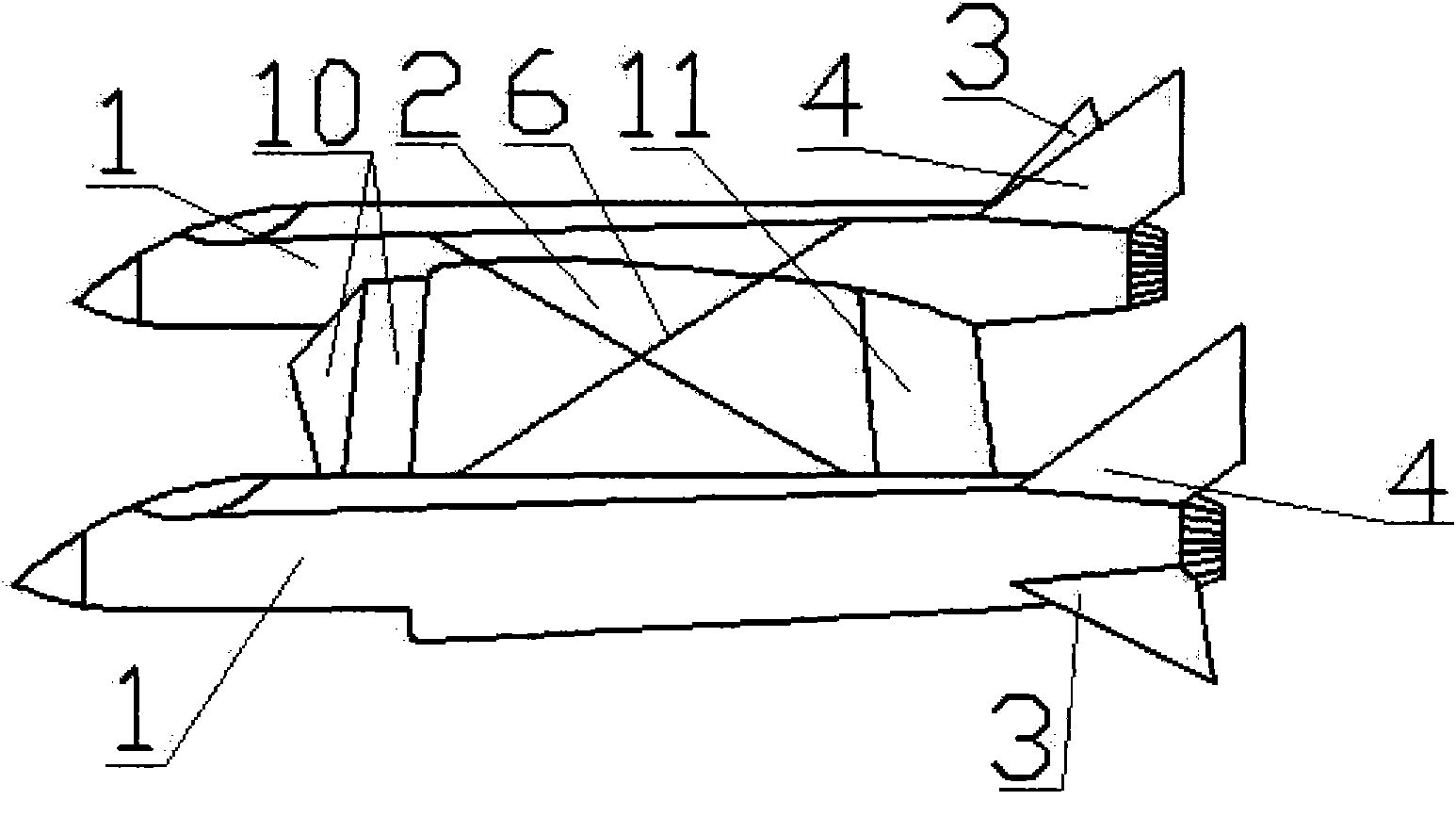

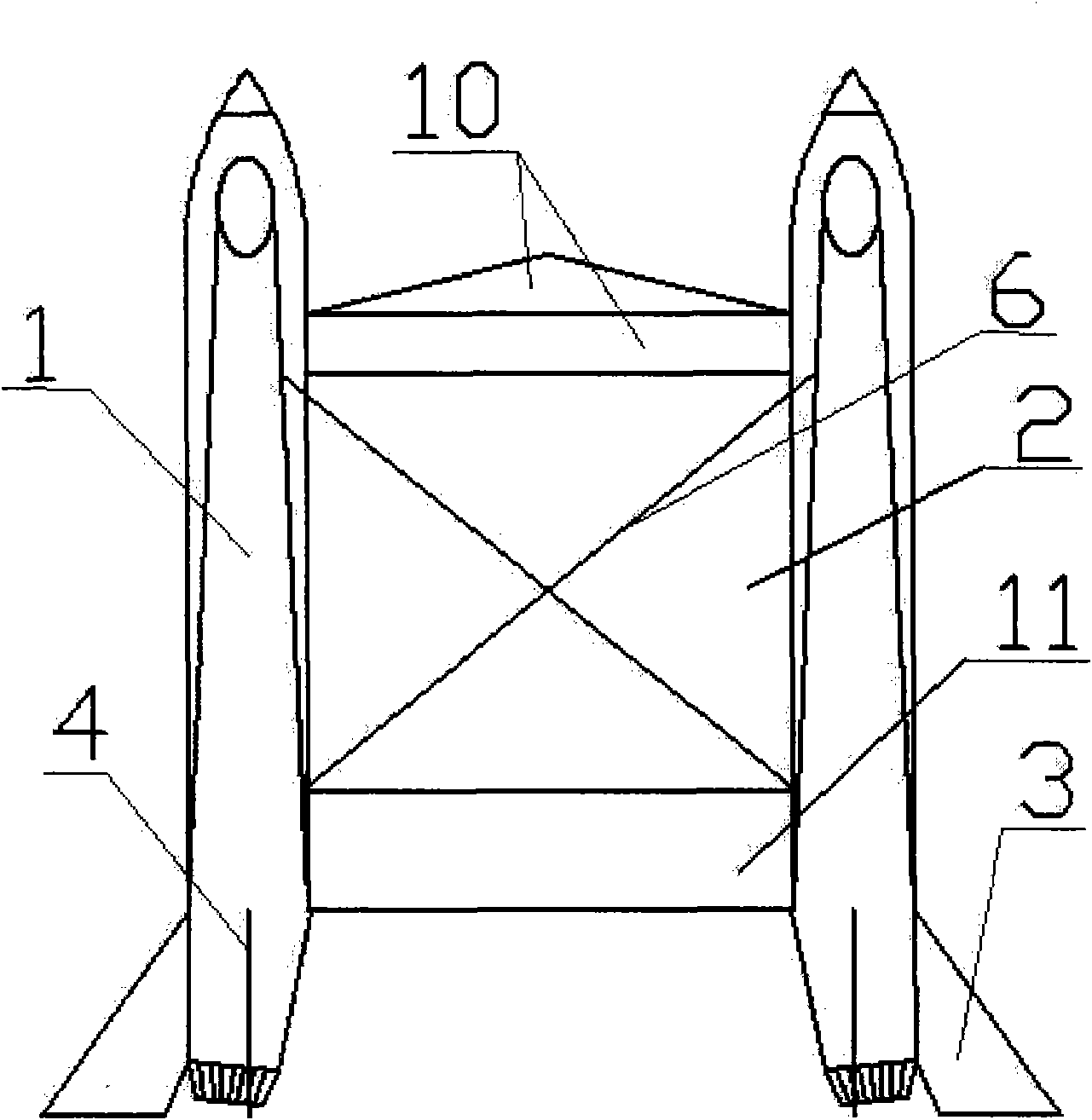

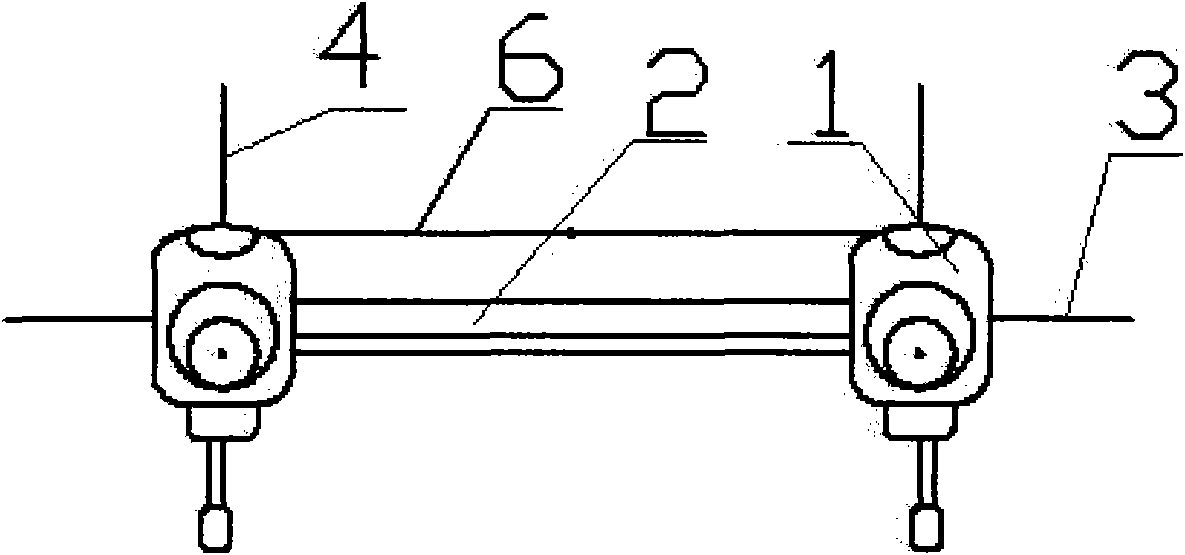

[0008] Such as figure 1 , figure 2 , image 3 Shown: the new aircraft wing layout scheme, there are two fuselages 1 arranged side by side, the overall design adopts jet engine propulsion, abdominal air intake, and advanced fly-by-wire control system at the tail of the fuselage 1, and the two fuselages 1 The lower part of the inner side of the body is connected by a rectangular main wing 2 that provides lift, and the tops of the two fuselages 1 are pulled together by wire cables 6 to prevent the two fuselages from separating outward due to gravity. The wing 2 will provide lift for the two fuselages 1, the wing chord is very long, and the two chords of the rectangular main wing 2 are connected with the fuselage 1, although the aspect ratio is very small, because there is no exposed wing end, it can also Effectively reduce the induced drag. Since the two fuselages are relatively far apart, in order to prevent the aircraft from rotating when only one engine is working in case o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com