Infrared photodeformable liquid crystal high-polymer nano composite material and preparation method thereof

A technology of nanocomposite materials and liquid crystal polymers, applied in liquid crystal materials, luminescent materials, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

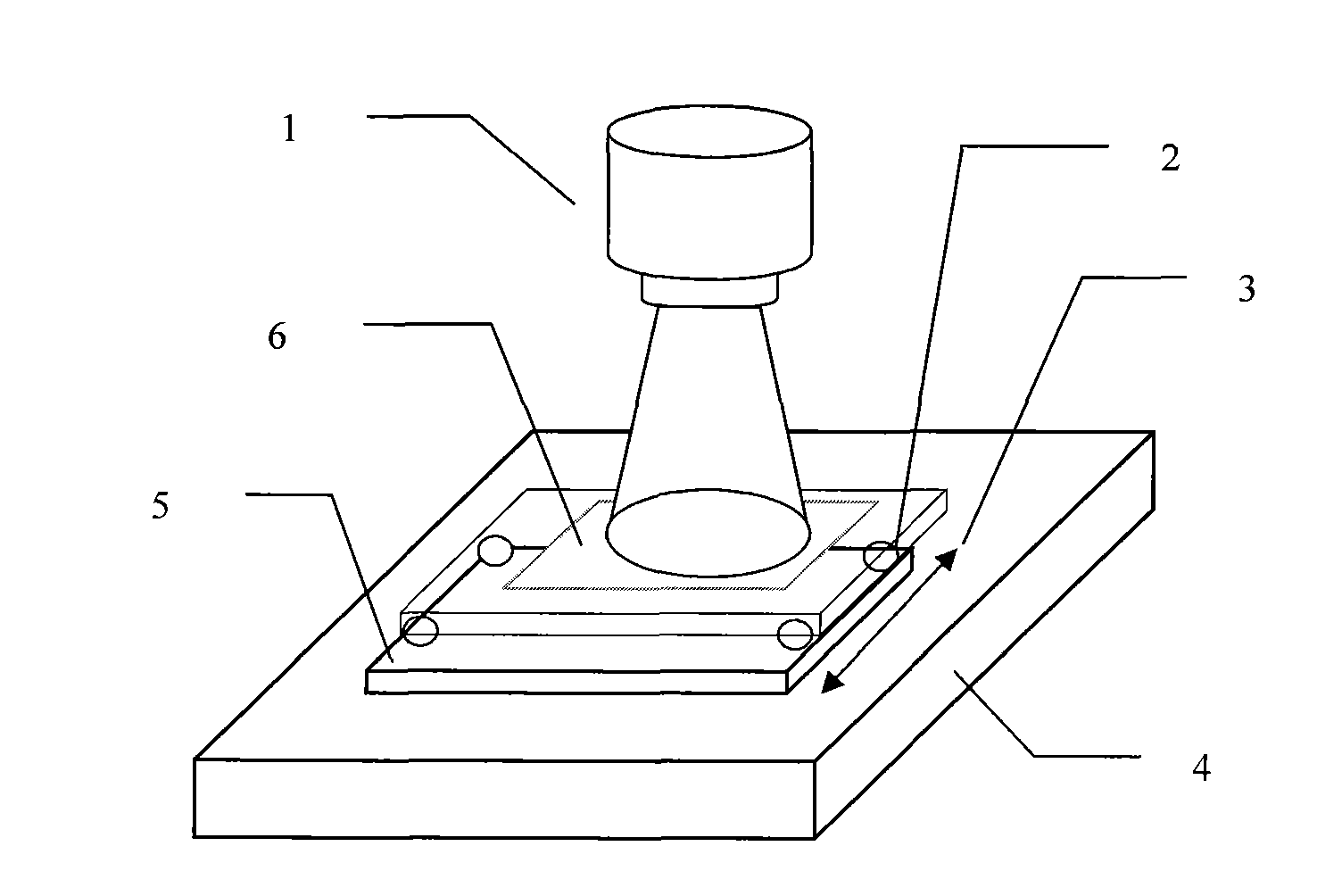

[0045] This example illustrates the process of preparing liquid crystal polymer nanocomposites according to the in-situ polymerization molding method of the present invention. See figure 1 As shown, first A11AB6 and DA11AB are mixed in a molar ratio of 90:10, then 5% of the sum of moles of A11AB6 and DA11AB is added as a photoinitiator, and then 10% of the sum of the mass of A11AB6 and DA11AB as rare earth luminescent nanoparticles is added. After mixing evenly, it is melted and injected into a liquid crystal cell 6 made of two substrates 5, and a spacer material 2 with a certain diameter is placed between the two substrates 5 to keep a certain distance between the two substrates 5 to control the prepared liquid crystal polymer nanometer. The thickness of the composite material, the inner surface of the substrate 5 is directional rubbed, so that the mesogens are aligned along the rubbing direction, the rubbing direction 3 is shown in the figure, and then the heating platform 4...

Embodiment 2

[0047] This example illustrates the process of preparing liquid crystal polymer nanocomposites according to the in-situ polymerization molding method of the present invention. See figure 1 As shown, at first A9ABT and DA9ABT are molar ratio of 90:10, then add A9ABT and DA9ABT molar sum of 5% thermal initiator azobisisoheptanonitrile, then add A9ABT and DA9ABT mass sum of 10% Rare earth luminescent nanoparticles. After mixing evenly, it is melted and injected into a liquid crystal cell 6 made of two substrates 5, and a spacer material 2 with a certain diameter is placed between the two substrates 5 to keep a certain distance between the two substrates 5 to control the prepared liquid crystal polymer nanometer. The thickness of the composite material, the inner surface of the substrate 5 is directional rubbed, in order to make the mesogens align along the rubbing direction, the rubbing direction 3 is shown in the figure, and then the heating platform 4 is used to control the re...

Embodiment 3

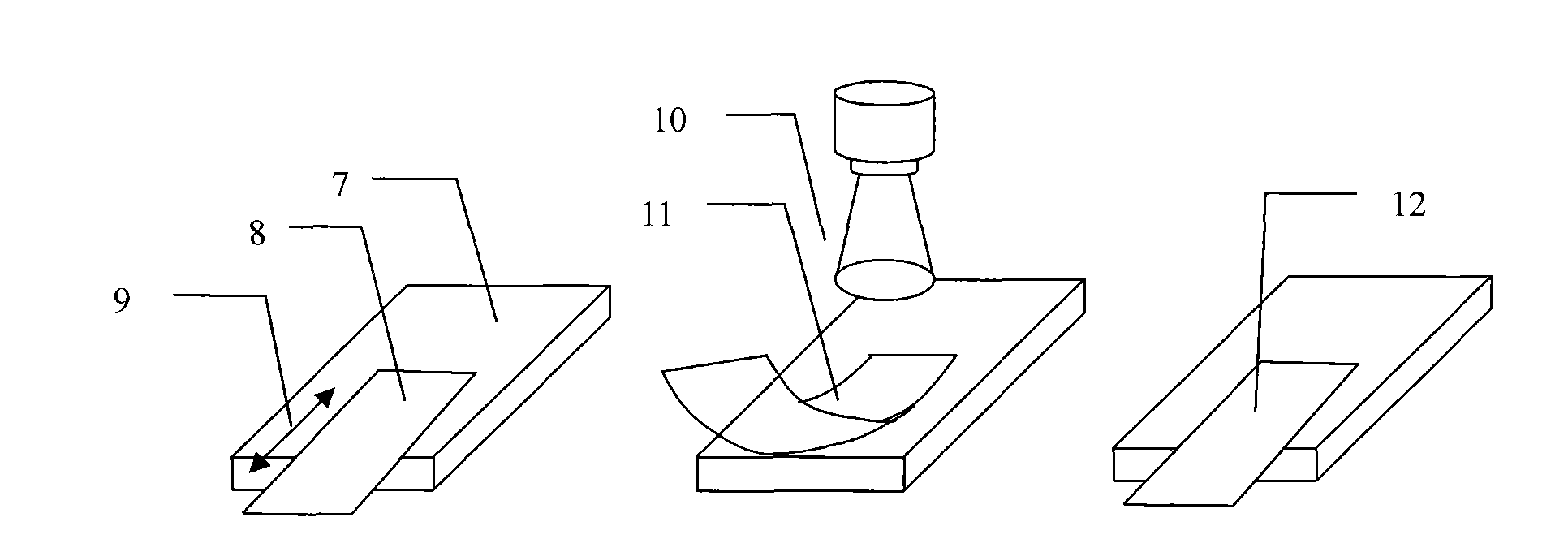

[0049] This example demonstrates the control of photodeformation of liquid crystal polymer nanocomposites. please see figure 2 As shown, the liquid crystal polymer nanocomposite material 8 obtained in Example 1 or Example 2 is placed on the substrate 7, and then the starting wavelength is 980nm and the power is 3W vertically above the liquid crystal polymer nanocomposite material 8. At this time, it can be observed that the liquid crystal polymer nanocomposite material 8 bends toward the light source along the rubbing direction 9 to form a deformed liquid crystal polymer nanocomposite material 11 . After the irradiation of the laser 10 is stopped, it can be observed that the deformed liquid crystal polymer nanocomposite material 11 has changed into the liquid crystal polymer material 12 returning to the initial state. This process can be repeated for many times, and the liquid crystal polymer material 8 There is no obvious fatigue in itself.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com