Transparent anti-static polyethylene thin film masterbatch

A polyethylene film, antistatic technology, applied in the field of polyethylene film masterbatch, can solve the problems of difficult processing, poor film transparency, large size, etc., and achieve good antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] With low-density polyethylene resin as carrier resin (Daqing Petrochemical Company product 2426H, melt flow rate is 2.0g / 10min, density is 0.9202g / cm 3 , molecular weight distribution is 4.25), water-soluble polymer is polyacrylic acid (Shandong Guoan Chemical Co., Ltd. product), polyethylene grafted maleic anhydride (Dalian Haizhou Chemical Co., Ltd. product), with 1,3,2,4-two (4-Methylbenzylidene) sorbitol (Shanxi Chemical Research Institute product) is used as transparent additive, with 1010 / 168 (1 / 1) (Ciba company product) as antioxidant, with zinc stearate (Shanghai New Jiu Chemical Co., Ltd.) is a dispersant.

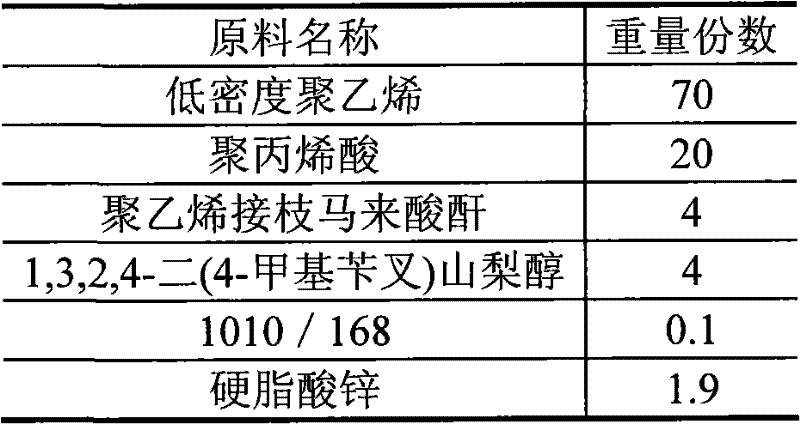

[0035] Each group distribution ratio in the embodiment 1 of table 1

[0036]

[0037] All the materials were put into a high mixer and mixed for 2 minutes, discharged, and pelletized by a twin-screw extruder with a screw speed of 100 rpm and a processing temperature of 220°C to obtain a transparent antistatic film masterbatch.

Embodiment 2

[0039] The water-soluble polymer is polyacrylamide (Hebei Songyang Chemical Industry Co., Ltd. product), and the transparent additive is two-(to-ethylbenzylidene isopropyl) sorbitol) (Mileliken company product), and others are with embodiment 1 .

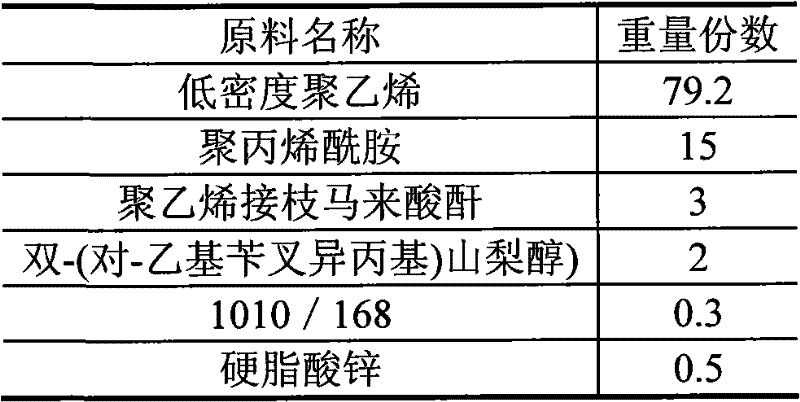

[0040]Each group distribution ratio in the embodiment 2 of table 2

[0041]

[0042] With the preparation method of Example 1, a transparent antistatic film masterbatch was prepared.

Embodiment 3

[0044] The water-soluble macromolecule is polyvinyl alcohol (product of Beijing Chemical Plant), and the transparent additive is p-chloromethyl dibenzylidene sorbitol (product of Milliken Company), with 1010 (product of Ciba Company) as antioxidant, other same Example 1.

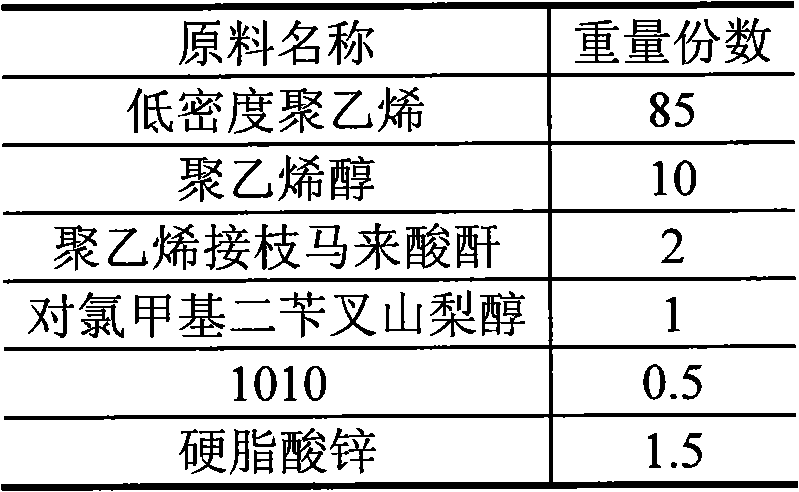

[0045] Each group distribution ratio in the embodiment 3 of table 3

[0046]

[0047] With the preparation method of Example 1, a transparent antistatic film masterbatch was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com