Mobile wine making device

A technology of equipment and mobile vehicles, applied in the field of mobile distillation and separation devices, can solve problems such as inability to flow, burnt odor, and inconvenient cleaning, and achieve the effects of convenient feeding and discharging, ensuring wine quality, and thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

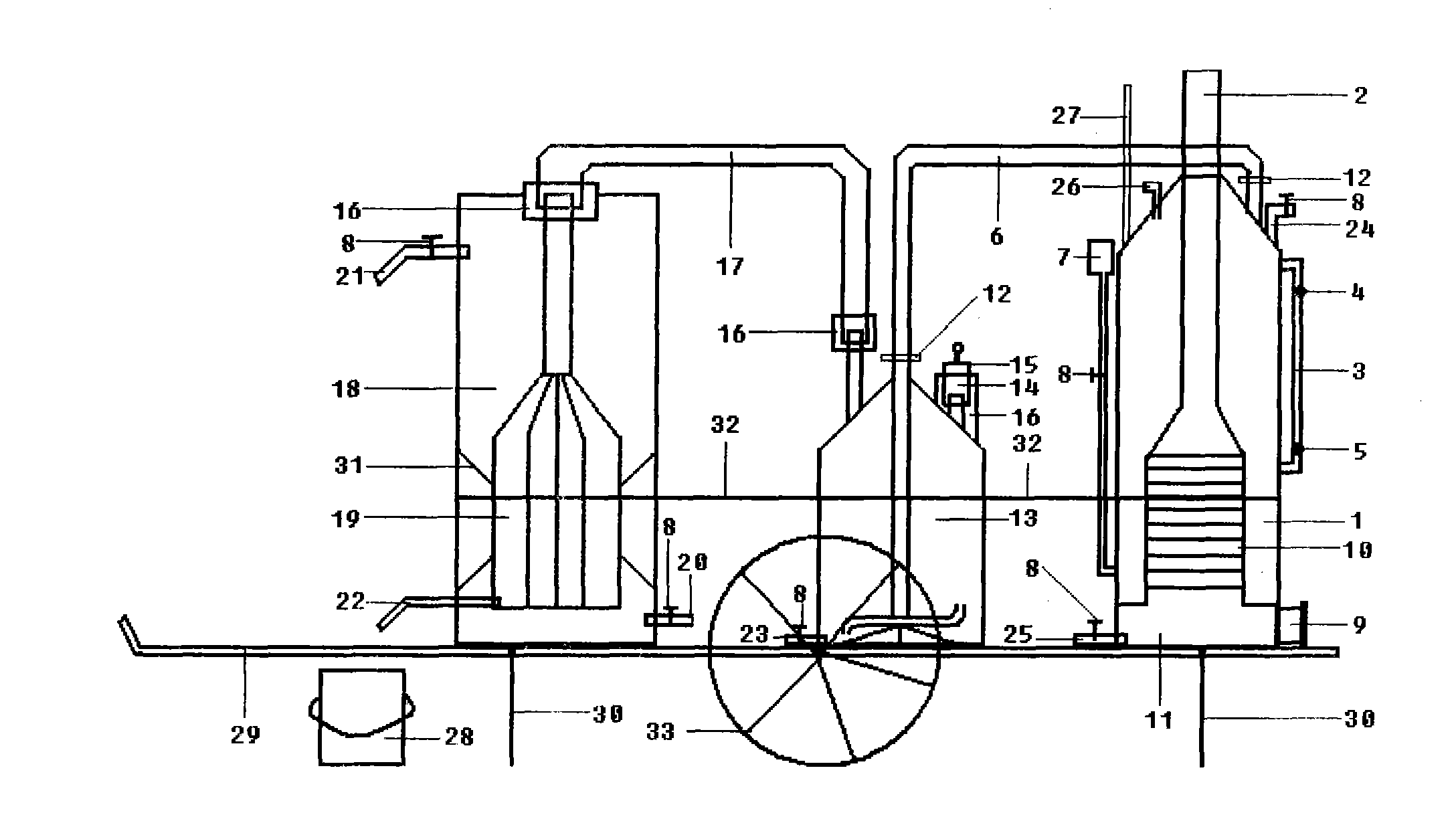

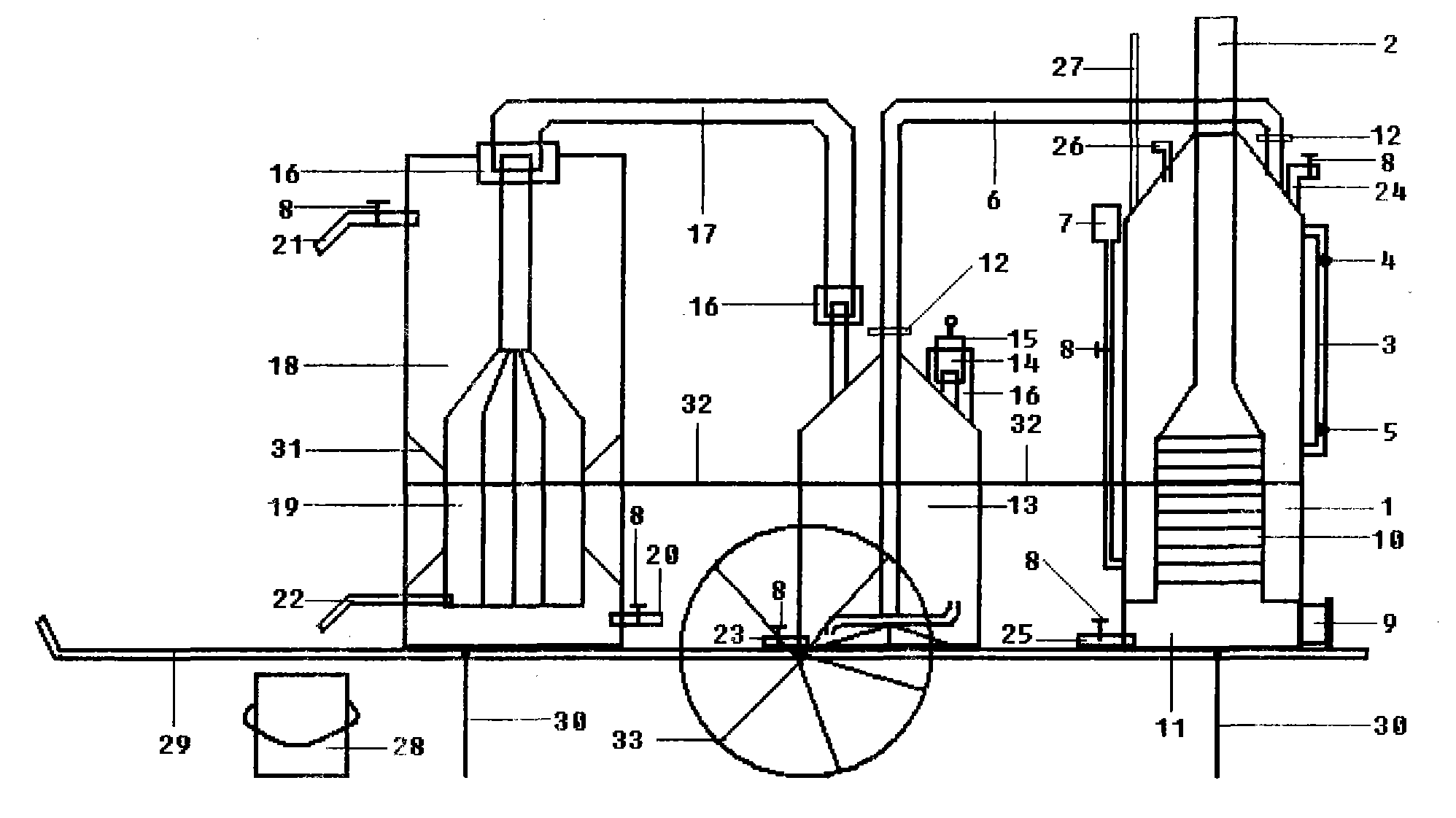

[0008] Referring to the accompanying drawings, the present invention includes an atmospheric pressure boiler 1, a waste skin barrel 13, a cooler 19 and a cooling pool 18, and the boiler 1, the waste skin barrel 13 and the cooler 19 are formed into a set through a steam delivery pipe 6 and a waste skin passing pipe 17 The distillation separation device is provided with a heat transfer tube 10 below the atmospheric pressure boiler 1, a smoke pipe 2 is provided on the top, a water level gauge 3, a water tank 7, a boiler safety pipe 27 and an air intake valve 26 are provided on the outer upper part, 13 is provided with feeding port 14, sealing cover 15 and water seal 16, is provided with the bad pipe 23 at the lower end of the bad skin bucket 13, and is provided with between the boiler (1), the bad skin bucket (13) and the cooling pool (18). There is a fixed iron ring (32) which plays a fixed role, and a mobile car (29) is arranged under the distillation separation device, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap