Heat treatment process of GCr15 steel bearing ring

A bearing ring and process technology, applied in the heat treatment process field of GCr15 steel bearing rings, can solve the problems of poor impact resistance, bearing brittle fracture failure, shortened service life, etc., and achieve the effect of simple process and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0013] Embodiment 1~6, the selection of carbon potential

[0014] In this group of examples, the bearing ring made of GCr15 steel is first heated to 830°C-860°C and held for 45 minutes; Nitrogen-based methanol atmosphere, using propane as the enriching agent, controlling the on-off of propane through the solenoid valve to adjust the carbon potential in the furnace), the comparison of carbon potential control and corresponding hardness (before tempering) results are shown in the following table:

[0015] serial number

[0016] In conclusion, carbon potential control has an influence on the hardness of GCr15 steel bearing rings, and the best carbon potential control is 0.62-0.71. If it is lower than 0.62, the hardness of the bearing ring is not enough. If it is higher than 0.71, the hardness will not increase much, but the cost will increase significantly.

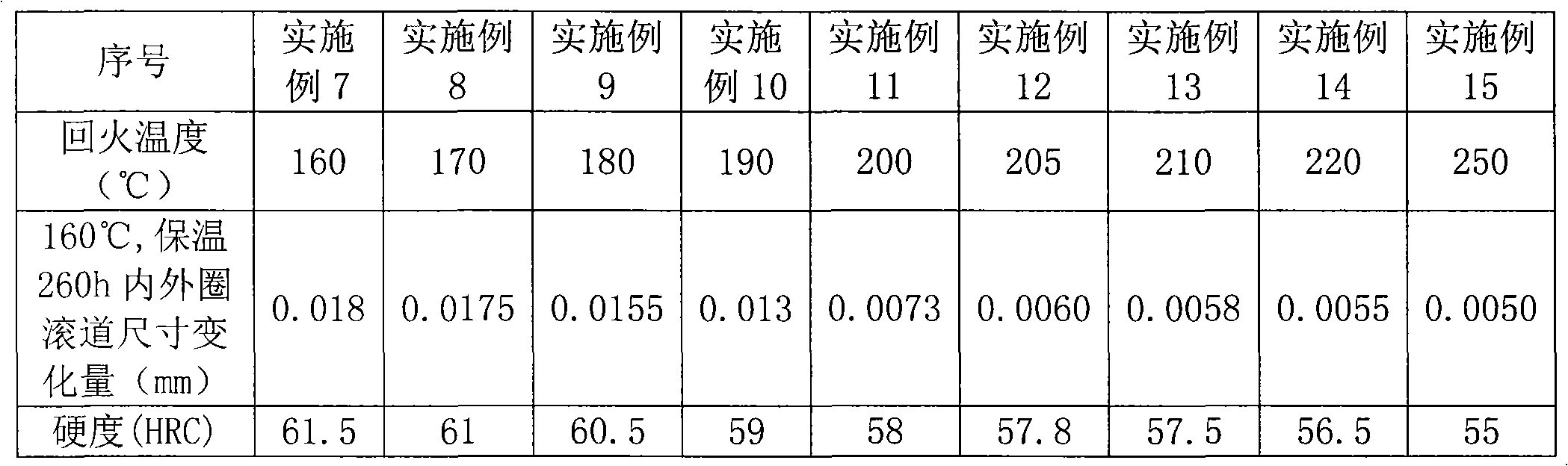

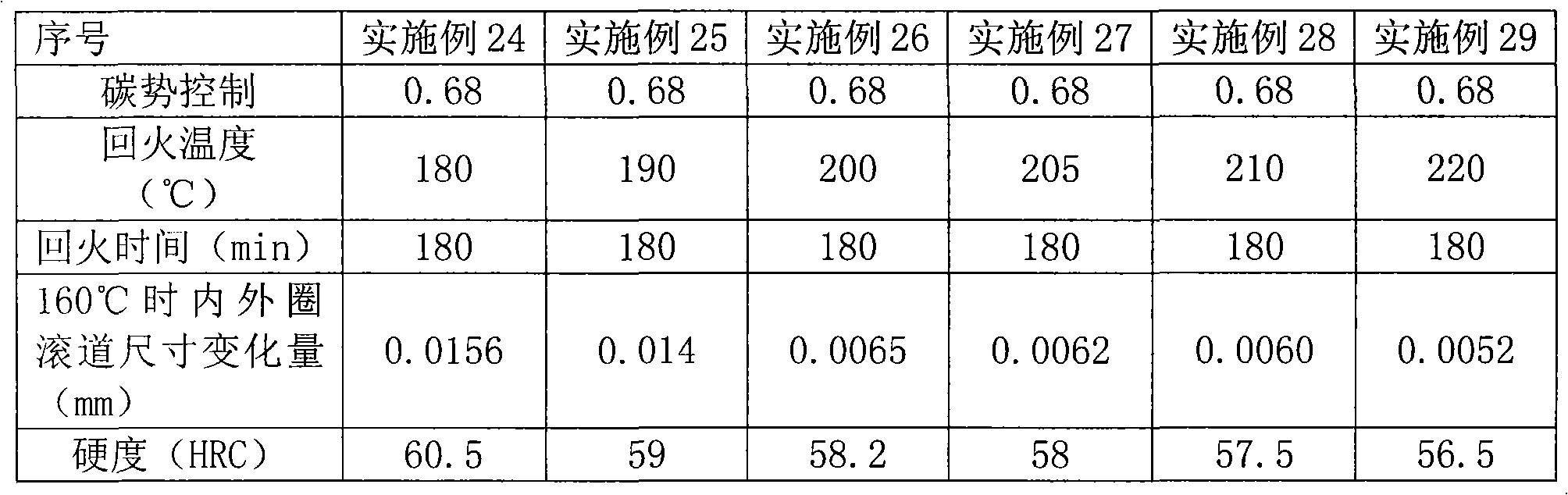

Embodiment 7~15

[0017] Embodiment 7~15, the selection of tempering temperature

[0018] In this group of examples, the bearing ring made of GCr15 steel is first heated to 830°C-860°C, held for 45 minutes, and the carbon potential is controlled to 0.68 (monitored by an oxygen probe and a carbon controller, and the atmosphere in the furnace is a nitrogen-based methanol atmosphere. , use propane as the enriching agent, and adjust the carbon potential in the furnace by controlling the on-off of propane through the solenoid valve.) Then quench in oil at 90°C, and then temper. The tempering holding time is 180min, and the tempering temperature and The results are compared in the table below:

[0019]

[0020] In conclusion, through appropriate process control, within the conventional tempering temperature range, there is a temperature selection area that can make GCr15 steel bearing rings work stably at high temperatures. When the bearing ring is at 160°C, the dimensional change (mm) of the inn...

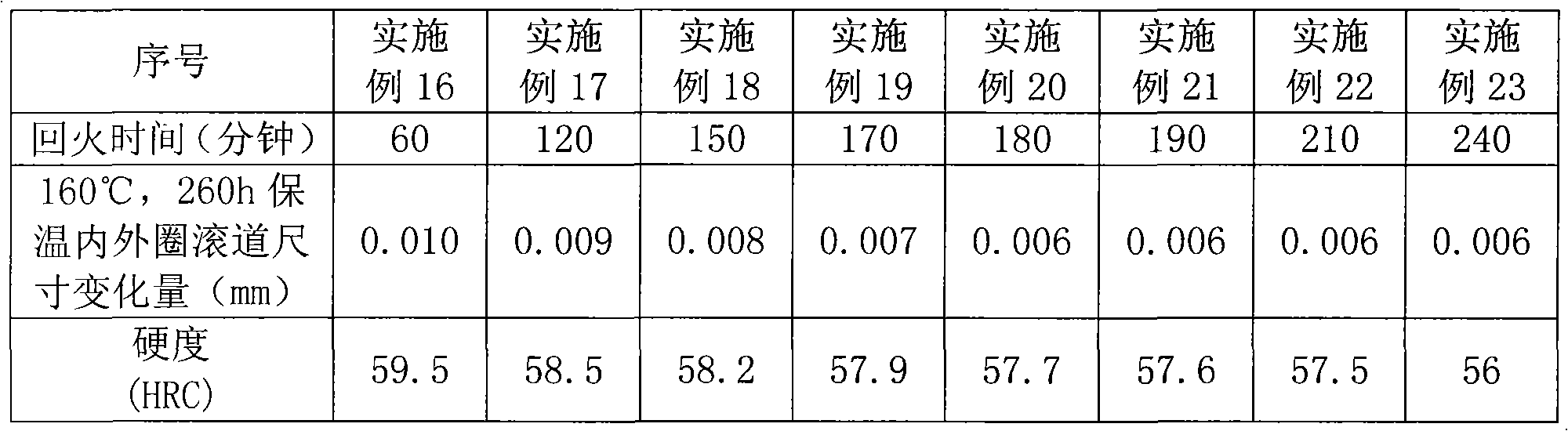

Embodiment 16~23

[0021] Embodiment 16~23, the selection of tempering holding time

[0022] In this group of examples, the bearing ring made of GCr15 steel is first heated to 830°C-860°C, held for 45 minutes, and the carbon potential is controlled to 0.68 (monitored by an oxygen probe and a carbon controller, and the atmosphere in the furnace is a nitrogen-based methanol atmosphere. Propane is used as the enriching agent, and the carbon potential in the furnace is adjusted by controlling the on-off of propane through the solenoid valve); after that, it is quenched in oil at 90°C, and then tempered. The tempering temperature is 205°C, and the tempering holding time and results See the table below for comparison:

[0023]

[0024] In conclusion, the tempering time has an influence on the high working temperature stability and hardness of the GCr15 steel bearing ring, and the best tempering time is 180min±10min, which is shorter than this tempering time for the high working temperature of the G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com