Method for directly leaching low-grade germanic lead oxide and zinc oxide ores

A low-grade lead-zinc oxide technology, applied in the direction of improving process efficiency, can solve the problems of high energy consumption, large pollution and low recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

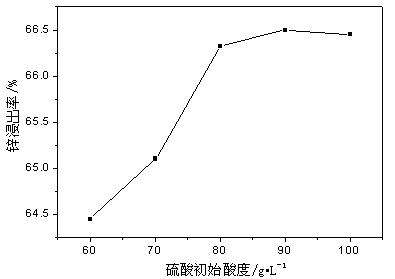

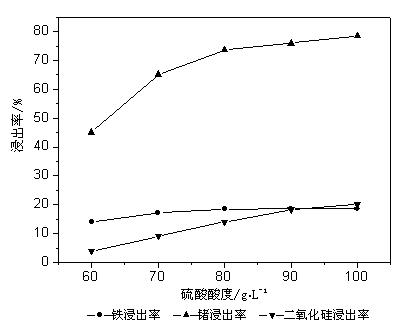

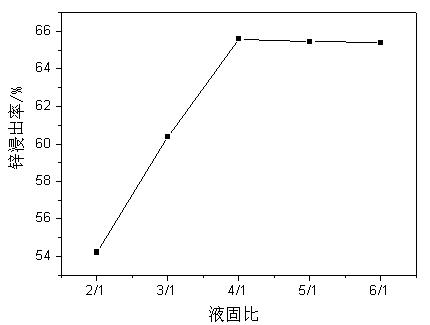

[0124] Embodiment 1 of the present invention: the process of directly leaching low-grade germanium-containing lead-zinc oxide ore. First, the ore sand with a zinc ion content of 8% and a germanium content of 80 g / T is added to the leaching tank, and the liquid-solid ratio is 5:1. The first leaching is performed by adding dilute sulfuric acid with a concentration of 90g / L. The leaching agent dilute sulfuric acid is added from the top of the leaching tank, and the solution is filtered out from the bottom of the leaching tank. The flow of the filtrate is controlled by the flow regulating valve, and the filtrate is returned to the leaching tank. And after 40 days of leaching at natural ambient temperature (according to the specific climate and location to determine the ambient temperature), filter out the leach residue to obtain leachate A; add raw ore containing zinc ions to the leachate A again, and add sulfuric acid to carry out the second The first leaching, after leaching at n...

Embodiment 2

[0126] Example 2: The process of directly leaching low-grade germanium-containing lead-zinc oxide ore. First, the ore sand with a zinc ion content of 5% and a germanium content of 40 g / T is added to the leaching tank, and the concentration is added according to a liquid-solid ratio of 4:1. For the first leaching of 75g / L dilute sulfuric acid, the leaching agent dilute sulfuric acid is added from the top of the leaching tank, the solution is filtered out from the bottom of the leaching tank, the flow of the filtrate is controlled by the flow regulating valve, and the filtrate is returned to the leaching tank, and in the natural After leaching at ambient temperature (according to the specific climate and location to determine the ambient temperature) for 60 days, filter out the leach residue to obtain leachate A; add raw ore containing zinc ions to the leachate A again, and supplement sulfuric acid for the second leaching. After leaching at natural ambient temperature for 60 days...

Embodiment 3

[0127] Example 3: The process of directly leaching low-grade germanium-containing lead-zinc oxide ore. First, the ore sand with a zinc ion content of 10% and a germanium content of 120g / T is added to the leaching tank, and the concentration is added according to a liquid-solid ratio of 3:1. 80g / L dilute sulfuric acid is used for the first leaching, the leaching agent dilute sulfuric acid is added from the top of the leaching tank, the solution is filtered out from the bottom of the leaching tank, the flow of the filtrate is controlled by the flow regulating valve, and the filtrate is returned to the leaching tank, and in the natural environment After leaching at high temperature for 30 days, filter out the leaching residue to obtain leach solution B; add raw ore containing zinc ions again, and supplement sulfuric acid for the third leaching, and then filter out the leaching residue after leaching at natural ambient temperature for 30 days. Obtain leach solution C, promptly obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com