Unloading device for realizing start-stop function of engine

An unloading device and engine technology, applied in engine control, machine/engine, output power, etc., can solve problems such as unstable starting and long starting time, and achieve the effects of reducing drag torque, reducing cylinder pressure, and reducing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation plan

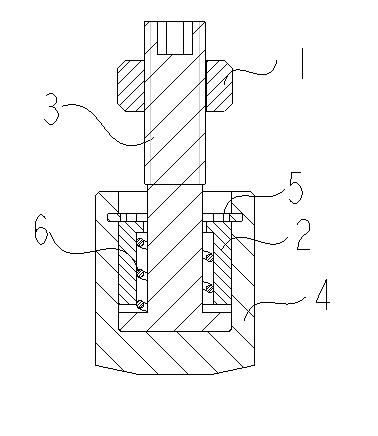

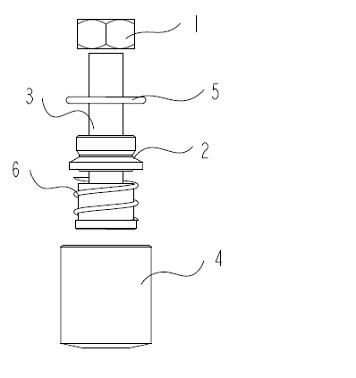

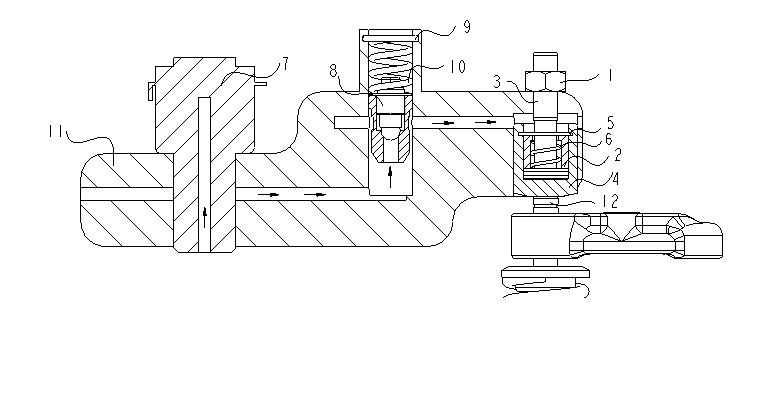

[0011] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 , 2 As shown, an unloading device for realizing the function of starting and stopping the engine is composed of a driven valve mechanism and a control oil circuit mechanism. , piston 4, retaining ring 5, and piston spring 6, in which the adjusting screw is fixed on the support frame, the gap between the adjusting screw and the limit sleeve is 1mm, which is the opening lift of the exhaust valve driven by the driven valve, and the limit sleeve Located inside the piston cavity, the piston spring is located inside the limit sleeve, the upper end surface of the limit sleeve is always in contact with the retaining ring, and the lock nut is used to fix the adjusting screw; the control oil circuit mechanism is composed of solenoid valve 7, control valve 8, control valve retaining spring 9. The control valve return spring 10 is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com