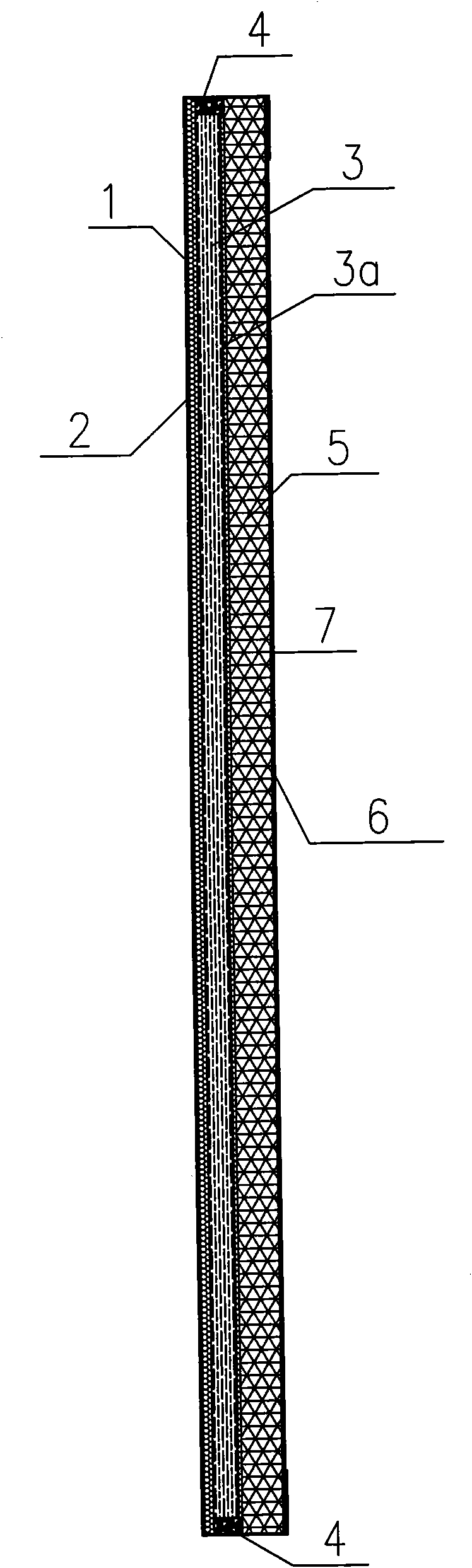

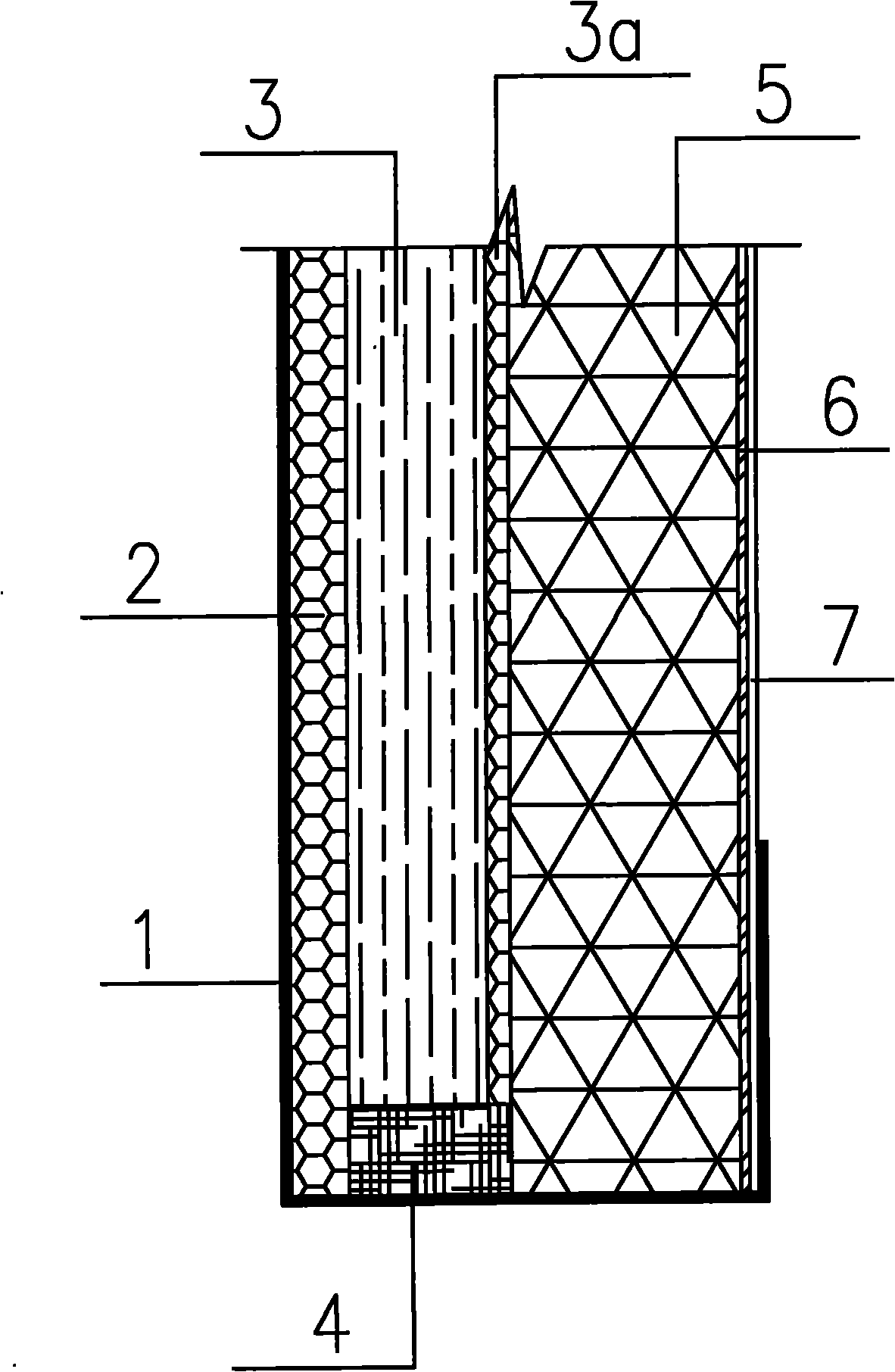

Multi-module impedance compound sound insulation plate and manufacturing method thereof

A technology of impedance compounding and sound insulation panels, which is applied in the direction of sound-generating devices and instruments, can solve the problems of unoptimized acoustic structure, easy damage to the structure of sound insulation panels, and low material utilization efficiency, so as to improve environmental adaptability and avoid Effects of destroying and guaranteeing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0064] The original acoustic conditions of the use environment: the noise sound pressure level is 106dB, the high sound pressure level frequency band appears above 600Hz, and the 1KHz sound pressure level in each frequency band is prominent, which is 112dB. Through noise reduction processing, the environmental noise must be below 65dB. The use environment of the sound insulation board is non-corrosive, and there is no special requirement for the appearance of the sound insulation board. In this example, the multi-module impedance composite sound insulation board is used as the shell of the equipment sound insulation cover. According to the size of the sound insulation cover, the multi-module impedance composite sound insulation board is square, and the length and width are 1200mm×600mm.

[0065] According to the design conditions, it can be obtained that the noise sound pressure level difference before and after noise reduction is 106-65=41dB, and the design value of the sound...

example 2

[0078] The original acoustic conditions of the use environment: the noise sound pressure level is 102dB, the high sound pressure level frequency band appears above 300Hz, and the 400Hz sound pressure level is prominent in each frequency band, which is 110dB. Through noise reduction processing, the environmental noise must be below 70dB. The use environment requires the use of wood veneer panels. In this example, the multi-module impedance composite sound insulation board is used as the partition wall panel. According to the shape requirements of the partition wall, the multi-module impedance composite sound insulation board is square, and the length and width are 1000mm×1000mm.

[0079] According to the design conditions, it can be obtained that the noise sound pressure level difference before and after noise reduction is 102-70=32dB, so the design value of the sound insulation of the multi-module impedance composite sound insulation board must be greater than 32dB. There is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com