Surface grinder spindle grinding disc device

A surface grinder and spindle technology, which is applied in the direction of grinding drive devices, grinders, transmission devices, etc., can solve the problems of difficult control of abrasive surface removal, poor line speed of grinding discs, and low line speed, so as to increase equipment utilization and repair Reduced number of times, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A. Drive mode of a variable frequency speed regulating motor:

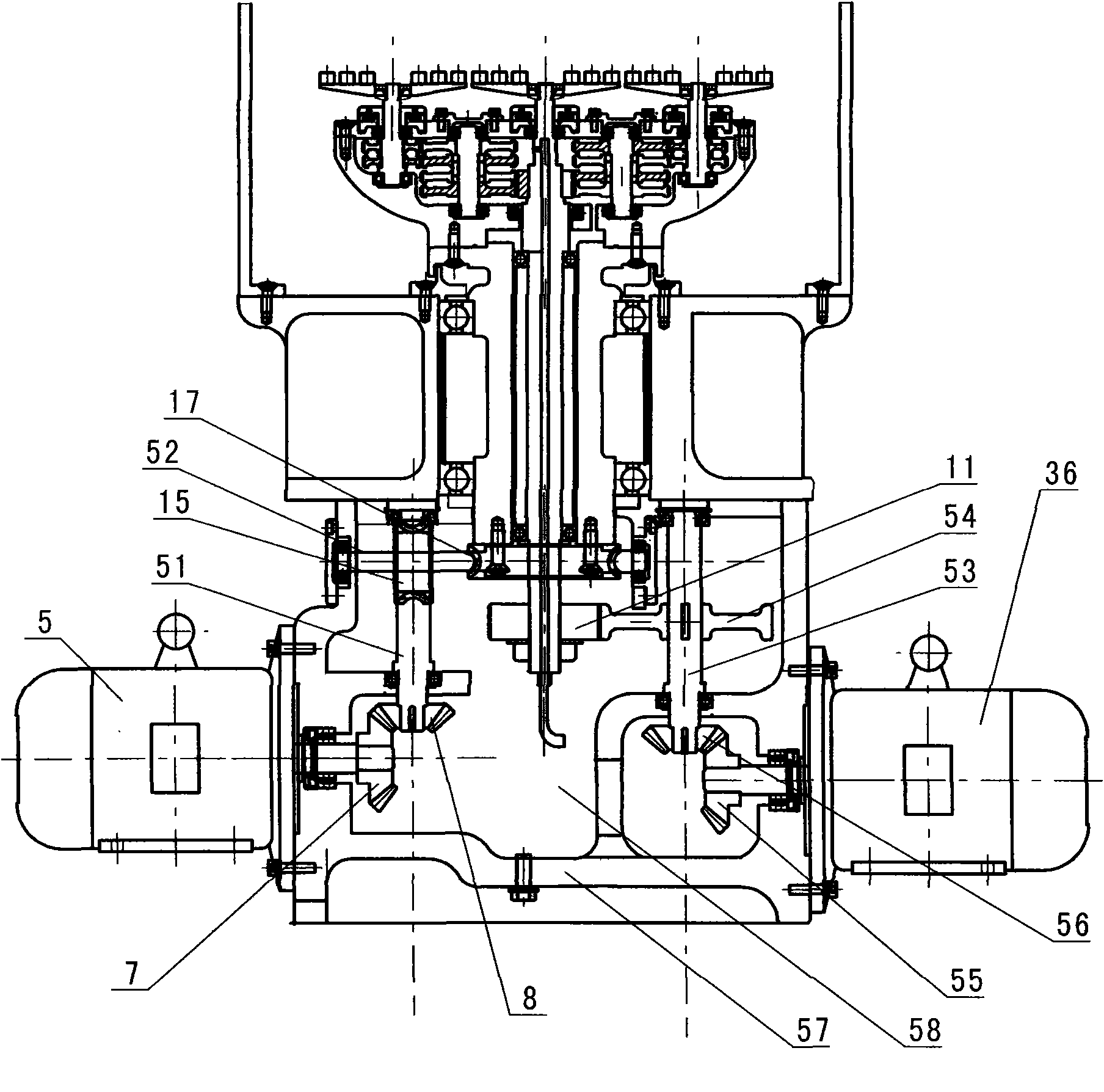

[0028] B. Drive mode of two variable frequency speed regulating motors:

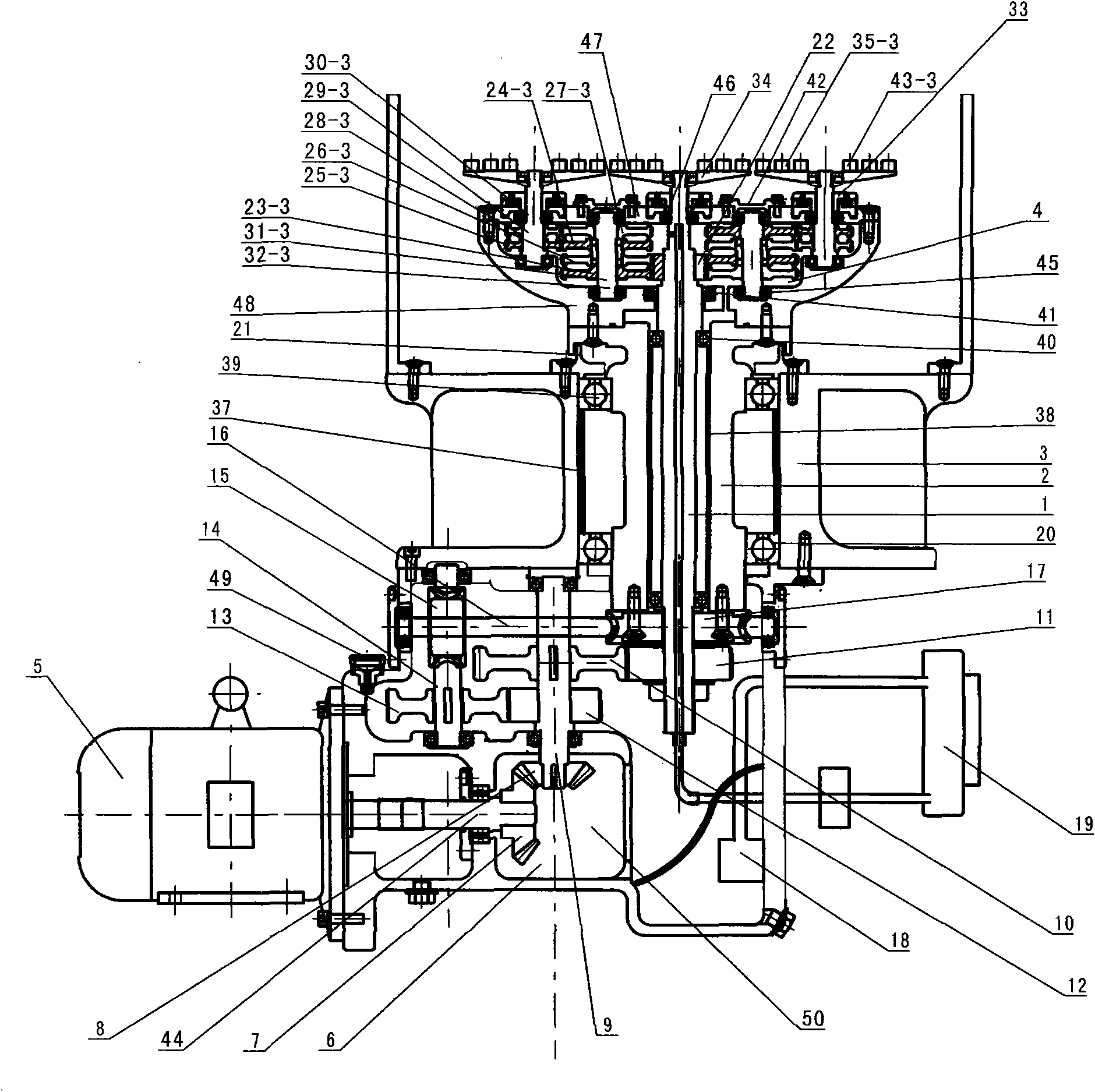

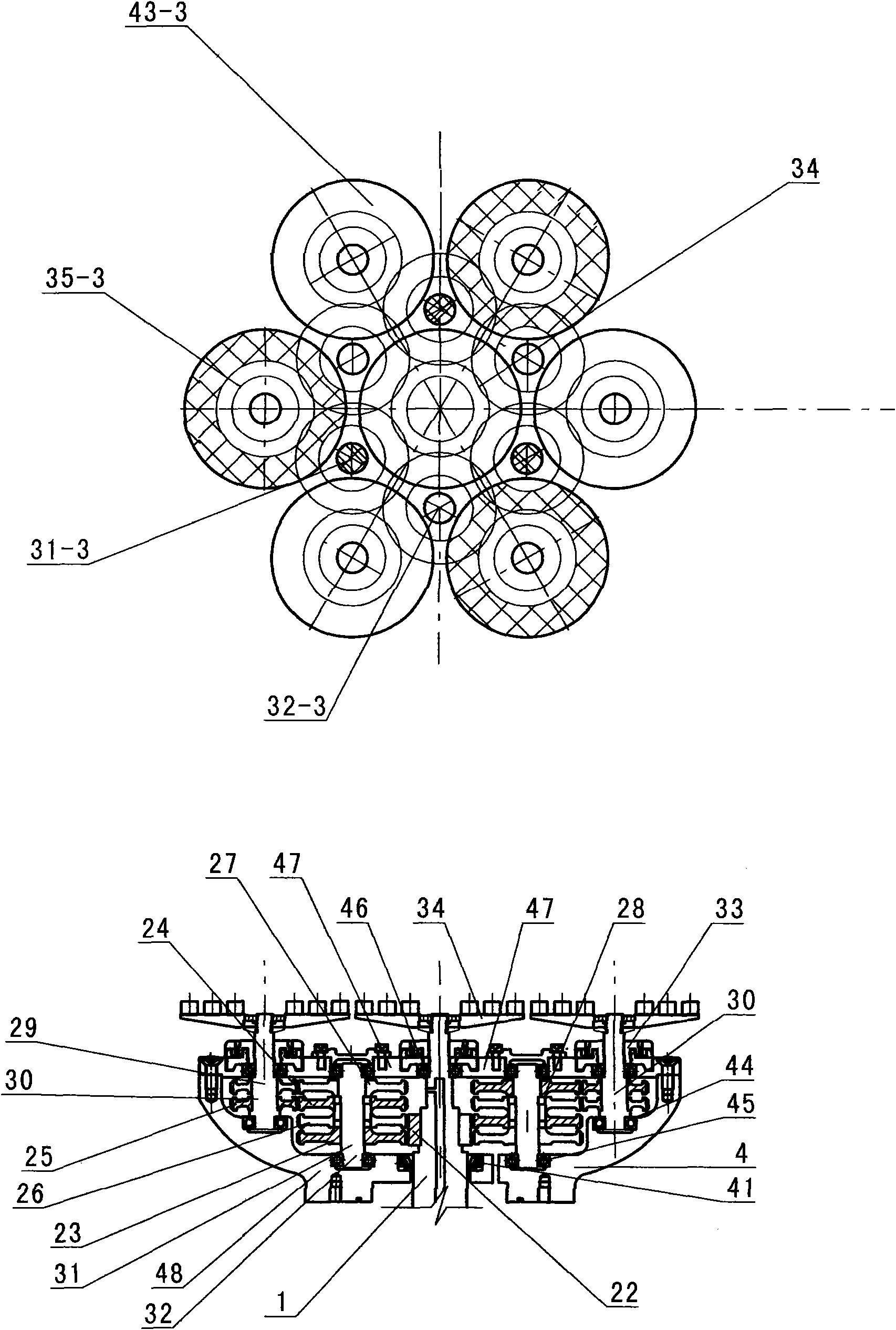

[0029] The A, see figure 1 ---2, the present invention includes machine base (3), lower gear box (6), planetary disk gear box (4), frequency conversion speed regulating motor (5), inner main shaft (1), outer main shaft (2), all The variable-frequency speed-regulating motor A (5) is fixed at a suitable position on the lower gear box, and the variable-frequency speed-regulating motor (5) is connected with the large bevel gear shaft (44) through a coupling, and the large bevel gear shaft (44) is fixed on the lower gear On the appropriate position in the casing (6), one end on the large cone gear shaft (44) is provided with the large cone driving gear (7) and the other end is connected with the shaft coupling.

[0030] The large conical driving gear (7) meshes with the small conical driven gear (8) to drive the small conical main driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com