Cooling method and cooling equipment for carbide slag

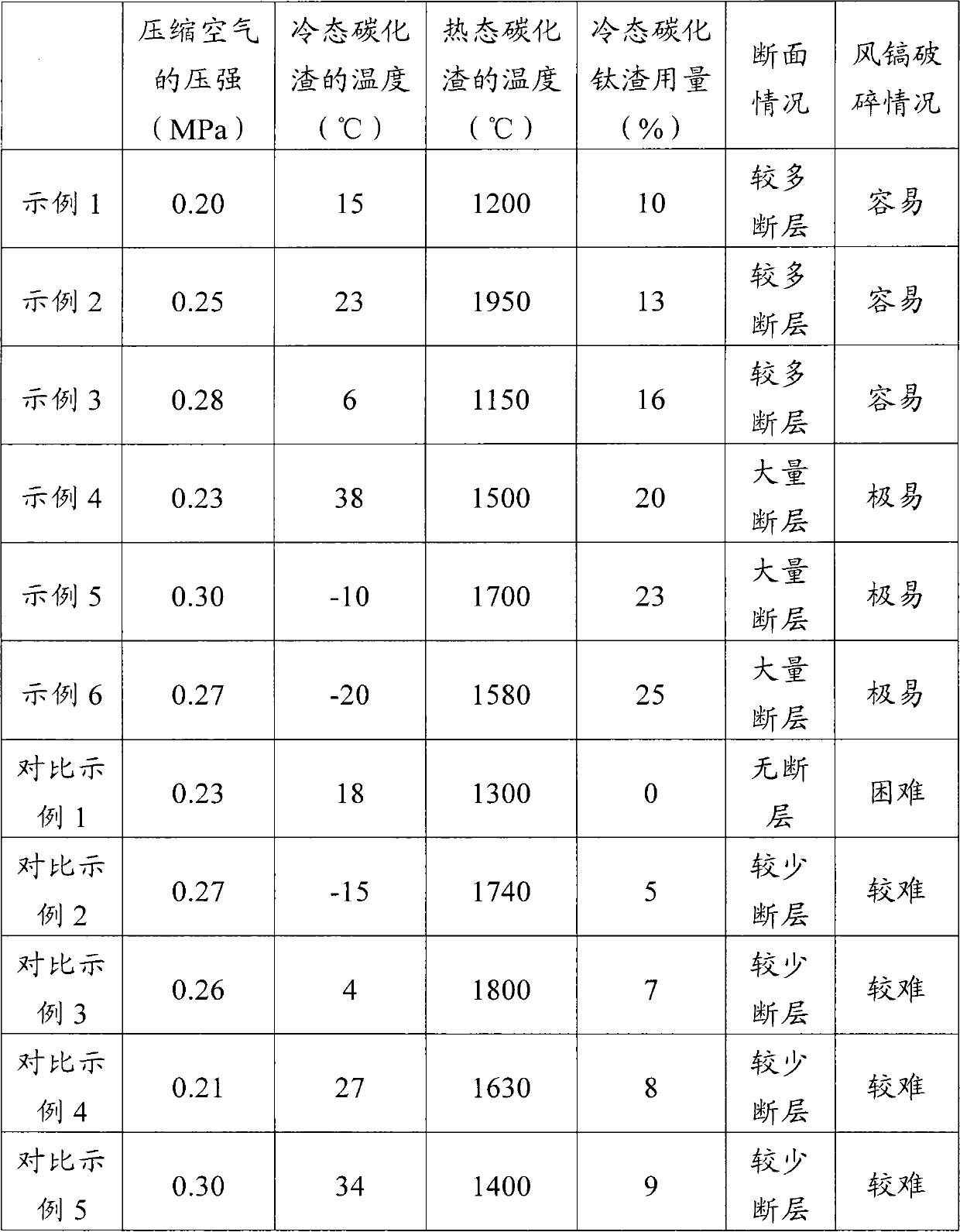

A technology of cooling equipment and a cooling method, which is applied in the field of cooling method and cooling equipment for carbide slag, can solve the problems of short service life of crushing equipment and difficulty in crushing carbide slag, and achieve the effects of easy crushing, pollution prevention, and reduced cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described below with reference to the accompanying drawings. Exemplary embodiments of the present invention are shown in the drawings, but these embodiments are provided only so that this disclosure will be thorough and complete, and will fully convey the principles of the present invention to those skilled in the art, It is not intended to limit the invention.

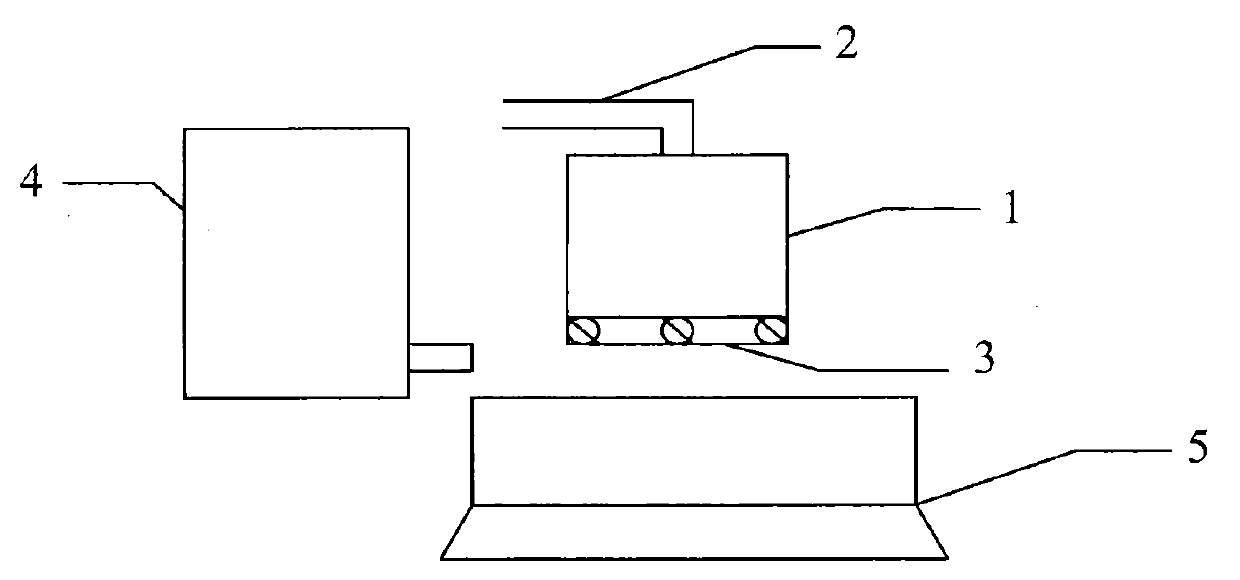

[0020] figure 1 is a schematic diagram of cooling equipment for carbide slag according to the present invention, referring to figure 1 , the cooling equipment of carbide slag of the present invention comprises: slag tank 1, is used for storing cold state carbide slag; Slag amount controller 3, is arranged on the bottom of slag tank 1, is used for controlling the slag output of cold state carbide slag; The tray 5 is arranged below the slag pot 1 and is used for receiving the hot carbide slag to be cooled discharged from the carbonization device 4 and the cold carbid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com