Special cable for top drive drilling and manufacture method thereof

A special cable and drilling technology, used in cable/conductor manufacturing, insulated cables, bendable cables, etc., can solve the problem of insufficient tensile properties, oil resistance and wear resistance, cannot ensure tight cable structure, and shorten cable life. and other problems, to achieve the effect of non-toxic environmental protection requirements, small tensile force, and optimized performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

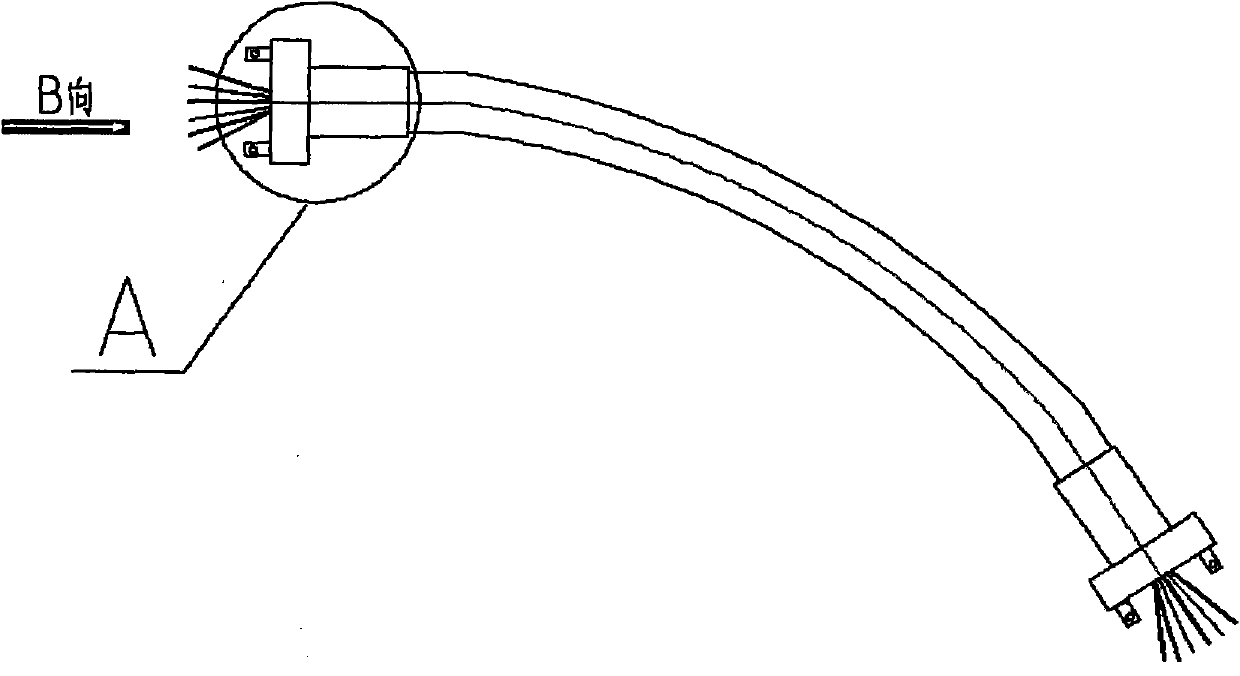

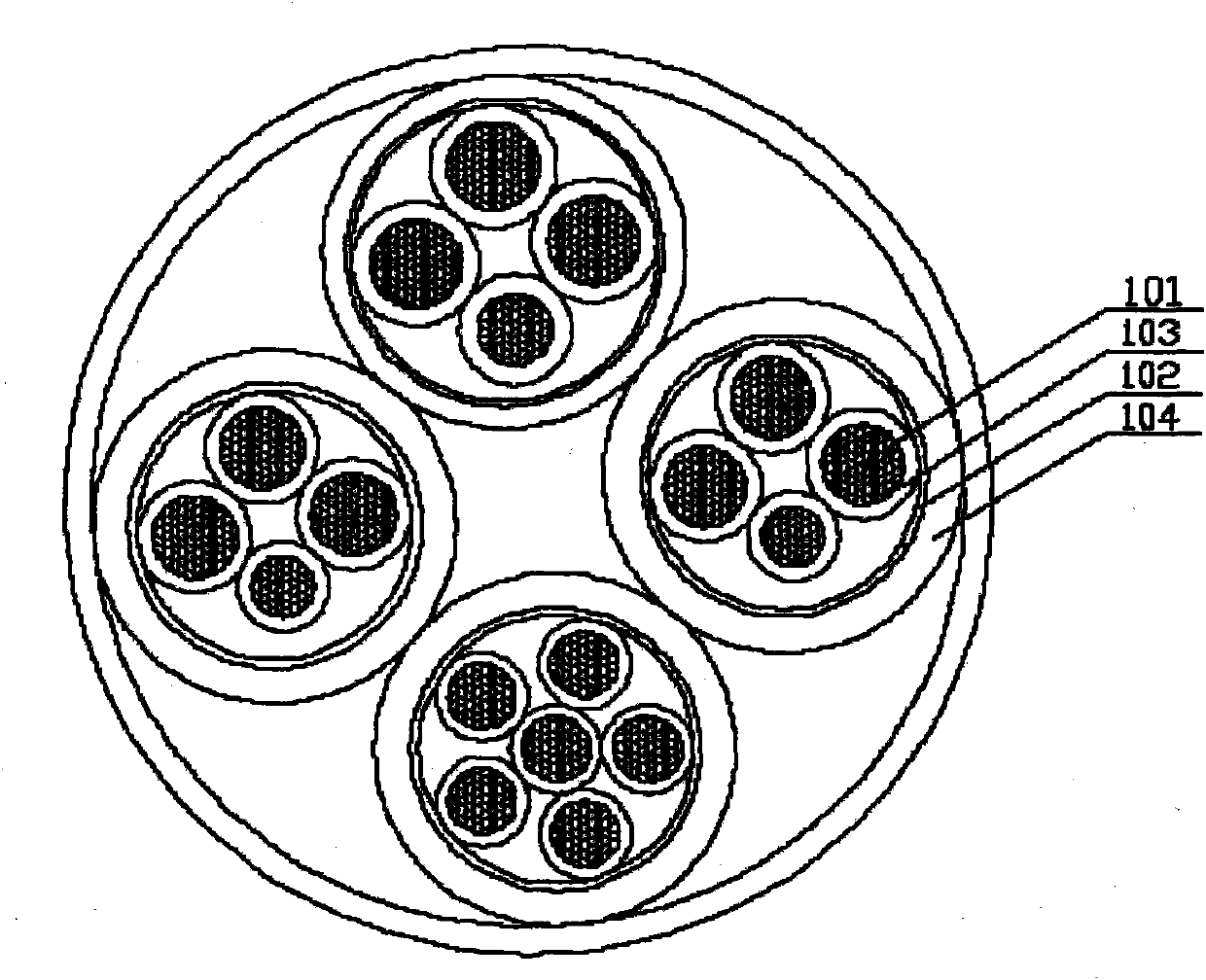

[0035] see figure 1 , figure 2 , image 3 .

[0036] The cable core 10 of this cable is sleeved in the casing, and the head of the cable core 10 protrudes from the casing, and the protruding cable core head is covered with a metal anti-scratch net 11 . The main body of the casing is a hose 8, which can be selected from one of oil-resistant rubber hose, oil-resistant rubber hose with cloth clamp, oil-resistant rubber hose with spring steel wire, oil-resistant rubber hose with cloth belt steel wire, preferably oil-resistant rubber hose with cloth belt steel wire. Tube. The end of the flexible pipe 8 is equipped with a metal pipe head, both ends of the power cable are equipped with a metal pipe head, and the control cable is only equipped with a metal pipe head at the hanging end. The metal pipe head is fixedly connected with the hose 8 as a whole. The metal pipe head is composed of a flange 5, an inner fastener 6 and an outer fastener 7. It is made of stainless steel. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com