Carbon/carbon composite material sealing ring and production method thereof

A technology of carbon composite materials and production methods, which is applied in the field of wear-resistant sealing parts, and can solve problems affecting the quality of rubber mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

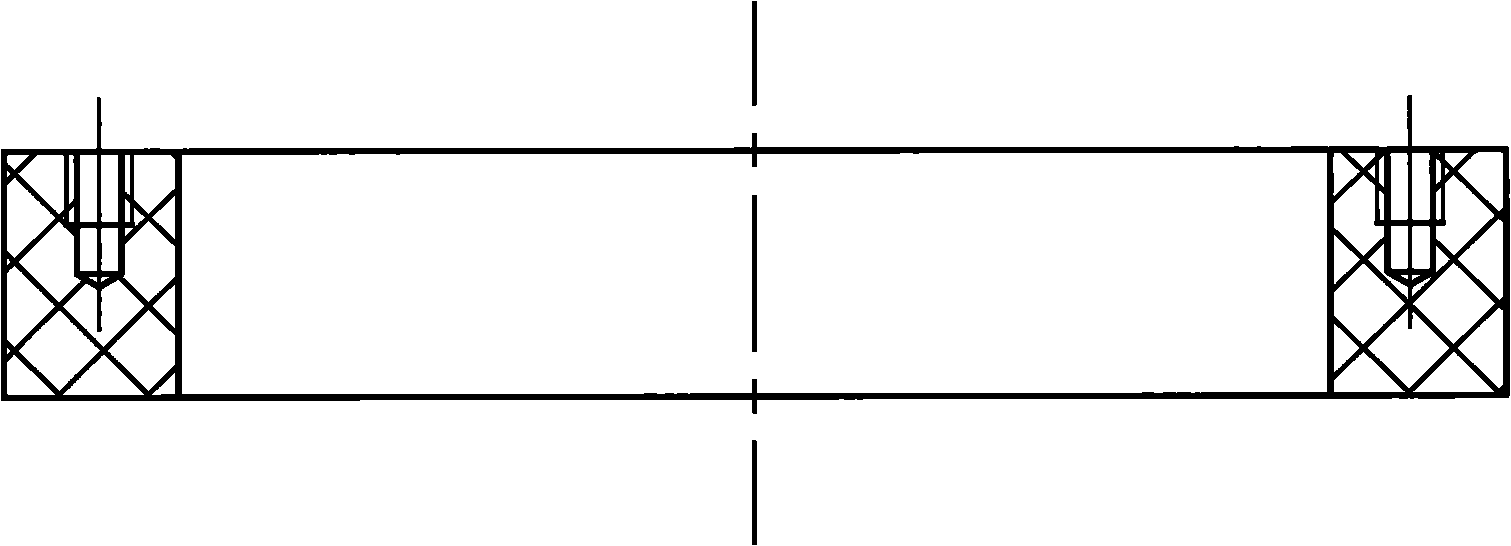

[0025] Depend on figure 1 It can be seen that a carbon / carbon composite sealing ring is made of carbon fiber through blanking-densification-machining, and the apparent density of the sealing ring is 1.2g / cm 3 ~2.0g / cm 3 (the present embodiment is 1.56g / cm 3 ).

[0026] A method for producing a carbon / carbon composite seal ring as above, comprising the following steps:

[0027] (1) Billet making: select short carbon fibers with a length of 6mm-70mm, and open them into fluffy needle-like fibers through an opening device, then air-laid and / or combed the opened carbon fibers into a net, and then use the net to lay The machine is laid into a fiber net and prepunched into a mesh tire. The mesh tire and carbon cloth made of carbon fiber are laminated and compounded by needling according to the required density to make a plate-like or ring-shaped prefabricated body (ring-shaped in this embodiment). The apparent density of the preform is 0.3g / cm 3 ~0.7g / cm 3 (the present embodim...

Embodiment 2

[0032] The apparent density of the sealing ring is 1.8g / cm 3 .

[0033] In order to shorten the production cycle and reduce costs in this embodiment, in step (2), after carrying out 2 cycles of chemical vapor deposition densification, the green body is put into an impregnation furnace and immersed in a thermoplastic resin (furan resin in this embodiment) ) for impregnation curing and densification. The apparent density of the green body after chemical vapor deposition densification reaches 1.2g / cm 3 , and then put the green body into the impregnation furnace for impregnation, solidification and densification, so that the apparent density of the green body reaches 1.8g / cm 3 , after graphitization treatment, made green body.

[0034] In impregnation curing and densification, the immersion temperature is 50°C-80°C, the pressure is 1MPa-3MPa, the immersion time is 1.5h-4h; the curing temperature is 160°C-230°C, the pressure is 1MPa-3MPa, and the curing time is 1.5h- 4h, 1 to 3 c...

Embodiment 3

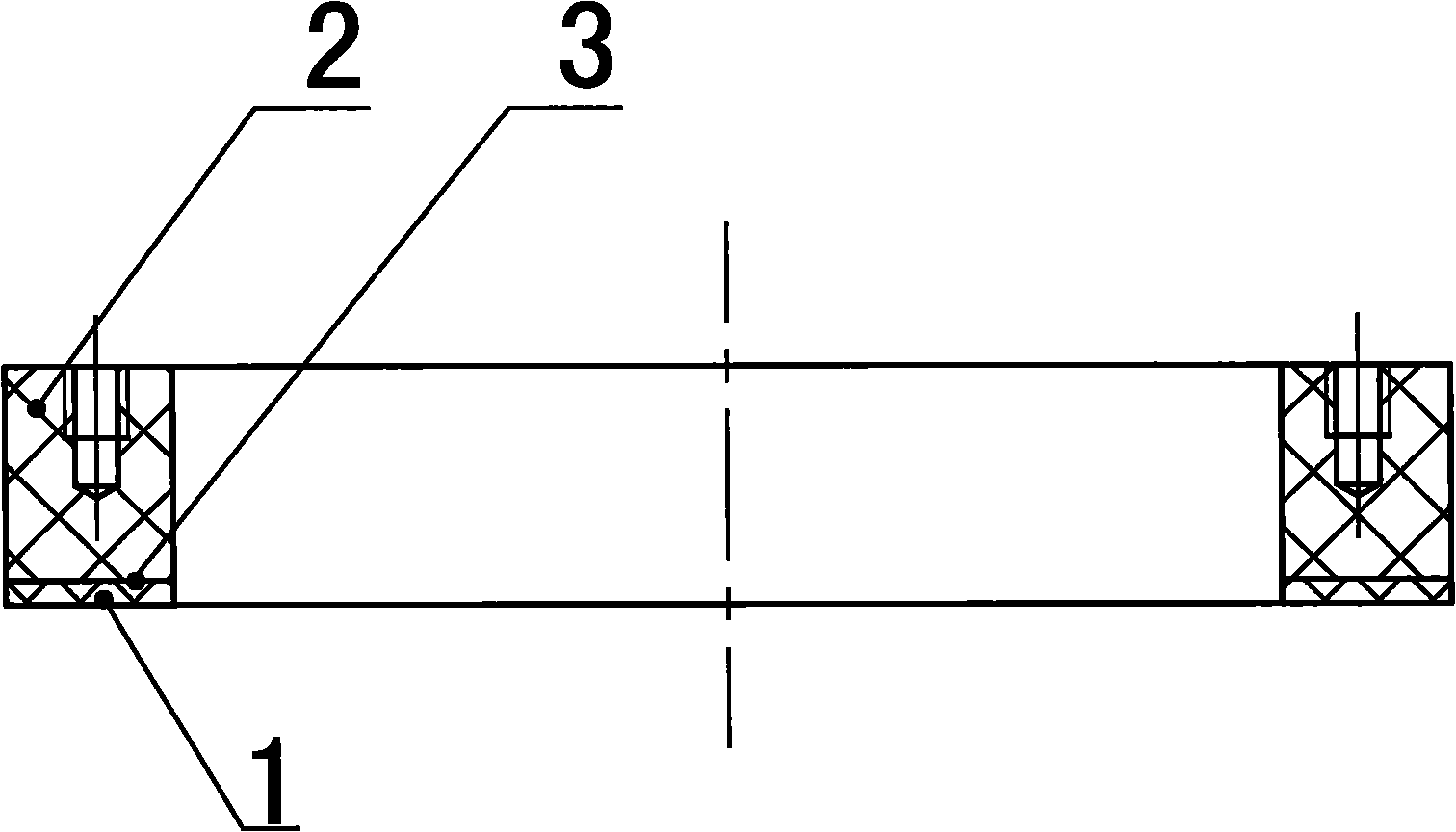

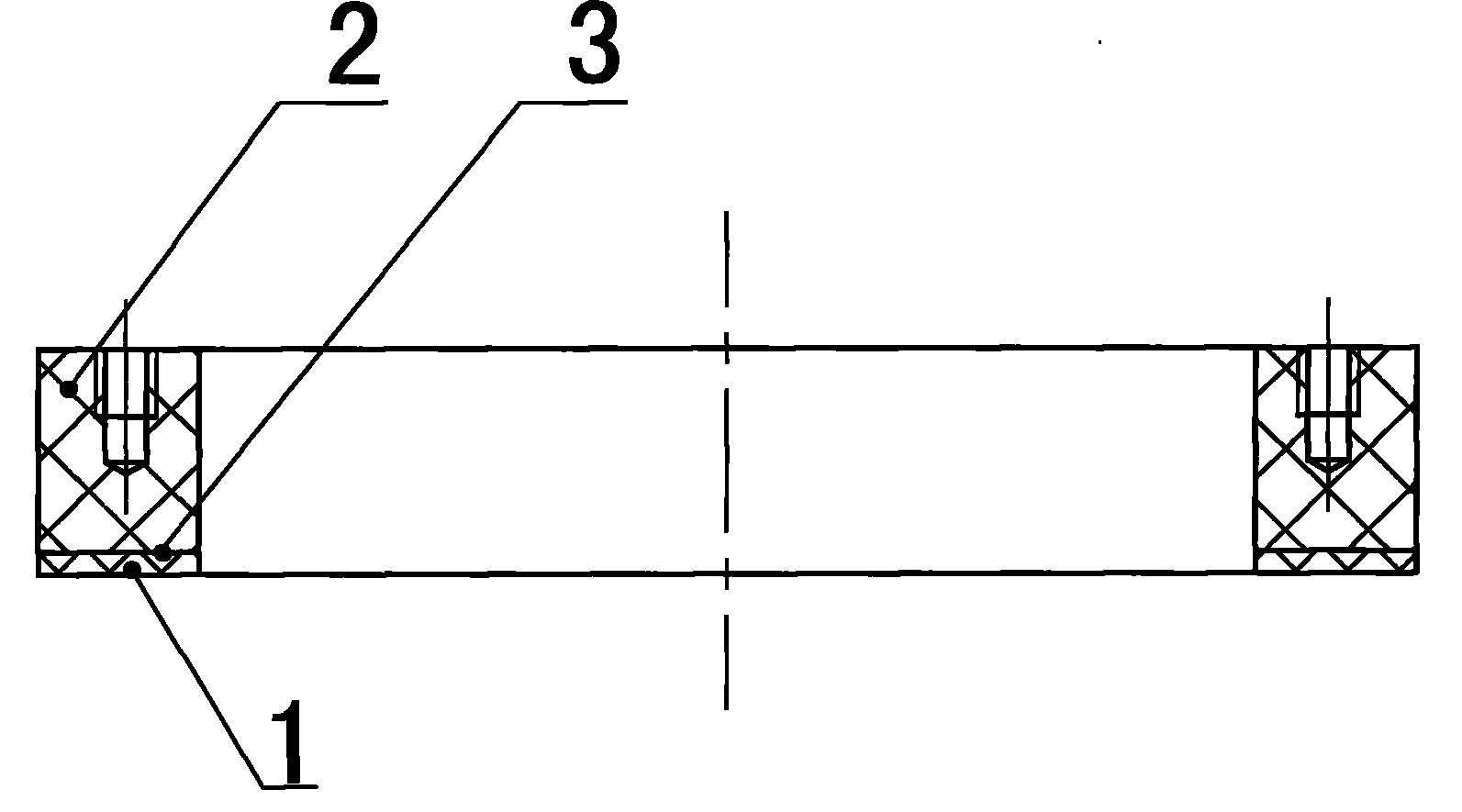

[0039] In order to reduce the production cost of the carbon / carbon composite sealing ring and improve the comprehensive performance, the friction surface and the ring body of the sealing ring adopt density gradient setting.

[0040] A carbon / carbon composite sealing ring, the sealing ring includes a friction surface 1 and a ring body 2, both of the friction surface 1 and the ring body 2 are made of carbon fiber through blank making-densification-machining, the surface of the friction surface 1 of the sealing ring The apparent density is 1.5g / cm 3 ~2.0g / cm 3 (the present embodiment is 1.8g / cm 3 ), the apparent density of ring body 2 is 1.2g / cm 3 ~1.8g / cm 3 (the present embodiment is 1.5g / cm 3 ).

[0041] A method for producing a carbon / carbon composite seal ring as above, comprising the following steps:

[0042] (1) Billet making: select short carbon fibers with a length of 6mm-70mm, and open them into fluffy needle-like fibers through an opening device, then air-laid and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap