Method for extracting and purifying microcystin

A technology of microcystin and purification method, which is applied in the field of extraction and purification of microcystin, can solve the problems of low sample loading, high cost, and low price, and achieve simple processing, low requirements, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

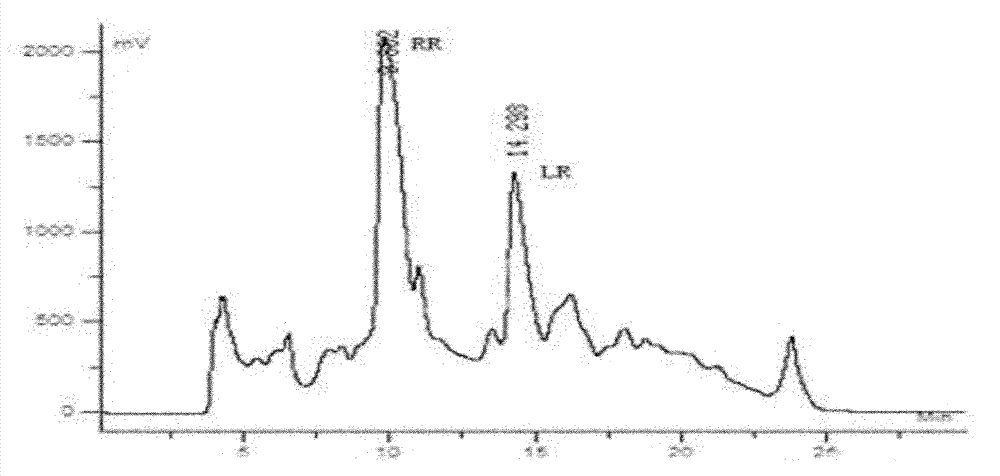

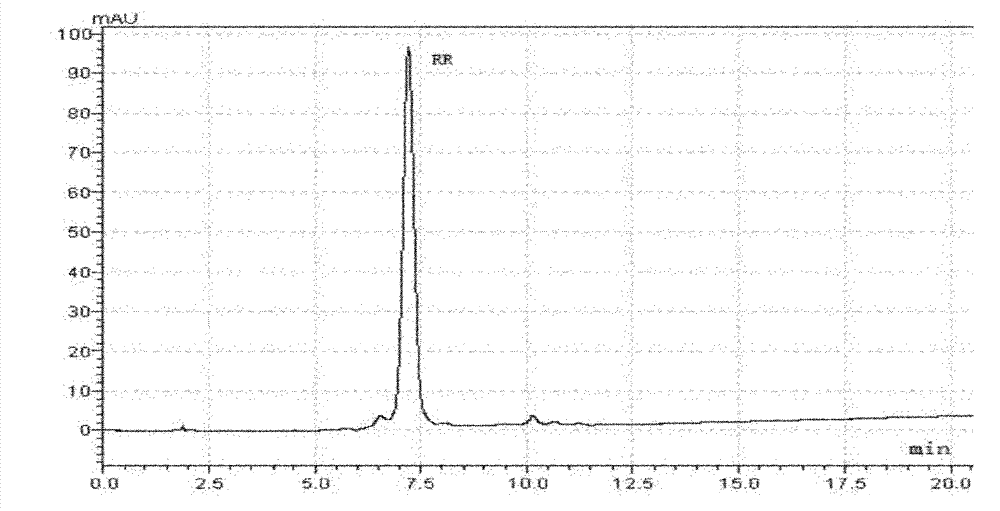

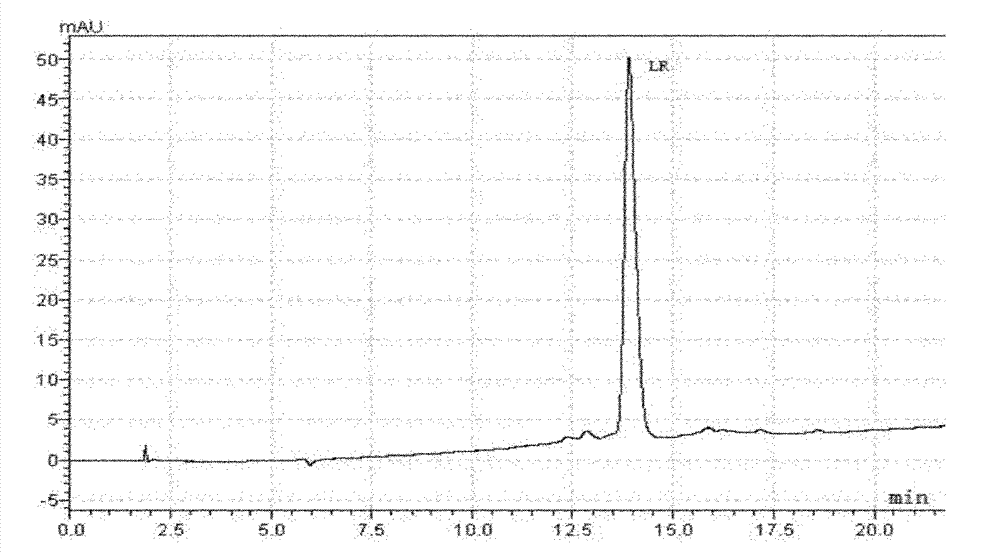

Image

Examples

Embodiment 1

[0032] A method for extracting and purifying microcystins, the operation steps are as follows:

[0033] 1. Weigh 3.000g of algae powder, put it into a 250ml Erlenmeyer flask, add 90ml of 60v / v% methanol to dissolve,

[0034] Shake at 200rpm at 8°C for 1h, then sonicate at 20°C for 20min, transfer to four 40ml plastic centrifuge tubes, centrifuge at 12000rpm at 20°C for 20min;

[0035] 2. Pour out the supernatant and combine it into a 200ml beaker, soak and wash the 4 parts of the precipitate obtained in step 1 with 50ml of 60v / v% methanol, then transfer all the 50ml cleaning solution into the original 250ml Erlenmeyer flask, shake at 200rpm at 8°C Shake for 1 hour, then ultrasonically induce solubilization at 20°C for 20 minutes, transfer to two 40ml plastic centrifuge tubes, centrifuge at 12,000 rpm for 20 minutes at 20°C, pour out the supernatant and combine it into the above-mentioned 200ml beaker;

[0036] 3. Adjust the above 6 combined supernatants to pH 3.7 with 1...

Embodiment 2

[0068] A method for extracting and purifying microcystins, the operation steps are as follows:

[0069] 1. Weigh 3.00g of algae powder, put it into a 250ml Erlenmeyer flask, add 100ml of 60v / v% methanol to dissolve, oscillate on a shaker at 200rpm at 15°C for 1h, and then ultrasonically induce dissolution at 25°C for 20min, then transfer to four 40ml plastic bottles Centrifuge tube, centrifuge at 12000rpm at 20°C for 20min;

[0070] 2. Pour out the supernatant and combine it into a 200ml beaker. The four precipitates obtained in step 1 are soaked and washed in 50ml of 60v / v% methanol, and then all the 50ml of the cleaning solution is transferred to the original 250ml Erlenmeyer flask, and shaker at 200rpm at 15°C Shake for 1 hour, and then ultrasonically induce solubilization at 25°C for 20 minutes, then transfer to two 40ml plastic centrifuge tubes, centrifuge at 12,000 rpm for 20 minutes at 20°C, pour out the supernatant and combine it into the above-mentioned 200ml beaker; ...

Embodiment 3

[0086] A method for extracting and purifying microcystins, the operation steps are as follows:

[0087] 1. Weigh 3.00g of algal powder, put it into a 250ml Erlenmeyer flask, add 120ml of 60v / v% methanol to dissolve, oscillate on a shaker at 200rpm at 20°C for 1h, and then ultrasonically induce dissolution at 30°C for 20min, then transfer to four 40ml plastic bottles Centrifuge tube, centrifuge at 12000rpm at 20°C for 20min;

[0088] 2. Pour out the supernatant and combine it into a 200ml beaker. The 4 parts of the precipitate obtained in step 1 are soaked and washed with 50ml of 60v / v% methanol, and then all the 50ml of the cleaning solution is transferred to the original 250ml Erlenmeyer flask and shaken at 20°C at 200rpm 1h, after ultrasonic solubilization treatment at 30°C for 20min, transfer to two 40ml plastic centrifuge tubes, centrifuge at 12000rpm at 20°C for 20min, pour out the supernatant and combine it into the above-mentioned 200ml beaker;

[0089] 3. Adjust the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com