Computational fluid dynamics (CFD)-based centrifugal pump multi-working condition hydraulic power optimization method

A hydraulic optimization and centrifugal pump technology, which is applied in the direction of pumps, non-variable pumps, non-displacement pumps, etc., can solve problems such as hydraulic optimization methods for multi-working conditions of centrifugal pumps that have not been seen in CFD, and achieve the goal of suppressing cavitation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

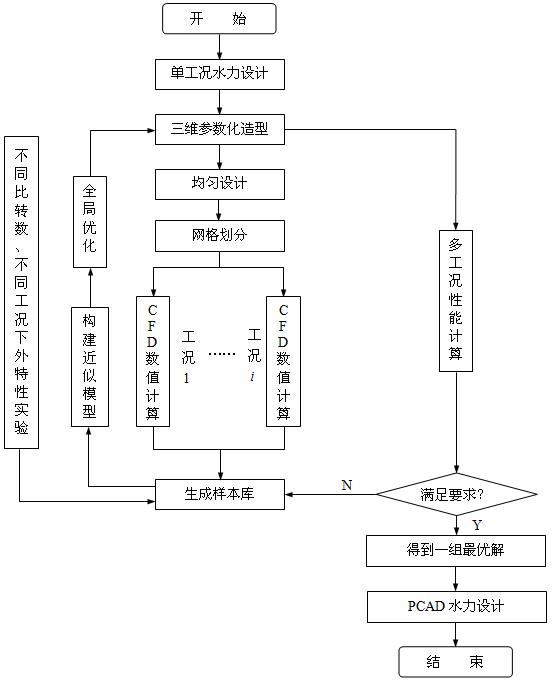

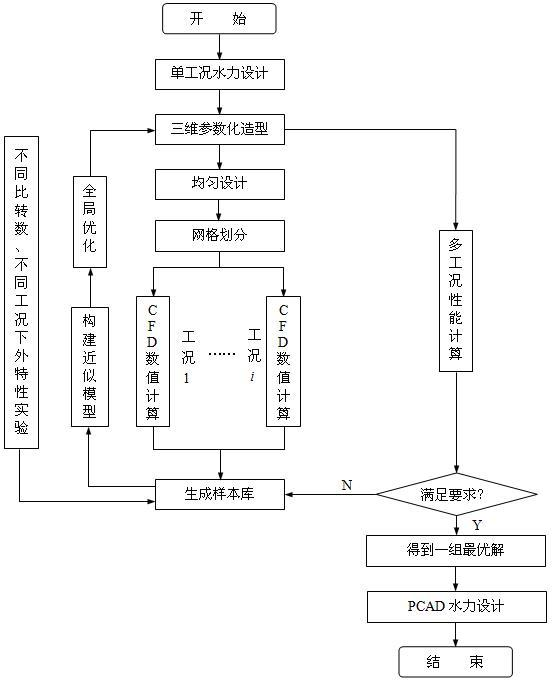

[0032] The flow of the CFD-based hydraulic optimization method for multi-working conditions of centrifugal pumps in this embodiment is as follows figure 1 shown, including the following steps:

[0033] (1) Based on the external characteristic experiment, the initial sample library for the multi-condition hydraulic optimization of the centrifugal pump is established.

[0034] Build a test bench for the external characteristics of centrifugal pumps; lift of centrifugal pumps H It is measured by the pressure gauges at the inlet and outlet of the centrifugal pump; the power of the centrifugal pump is measured by the electric method P ; Centrifugal pump flow Q It is read by the electromagnetic flowmeter on the outlet piping system of the centrifugal pump; the efficiency of the centrifugal pump n by the formula n = ρ g QH / P .

[0035] The key ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com