Non-air power driven sucker device

A power-driven, airless technology, applied in the direction of suction cups, connecting components, mechanical equipment, etc., can solve the problems of suction cup products without structure, increase production costs, noise pollution, etc., to reduce power consumption, reduce equipment costs, and eliminate noise pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

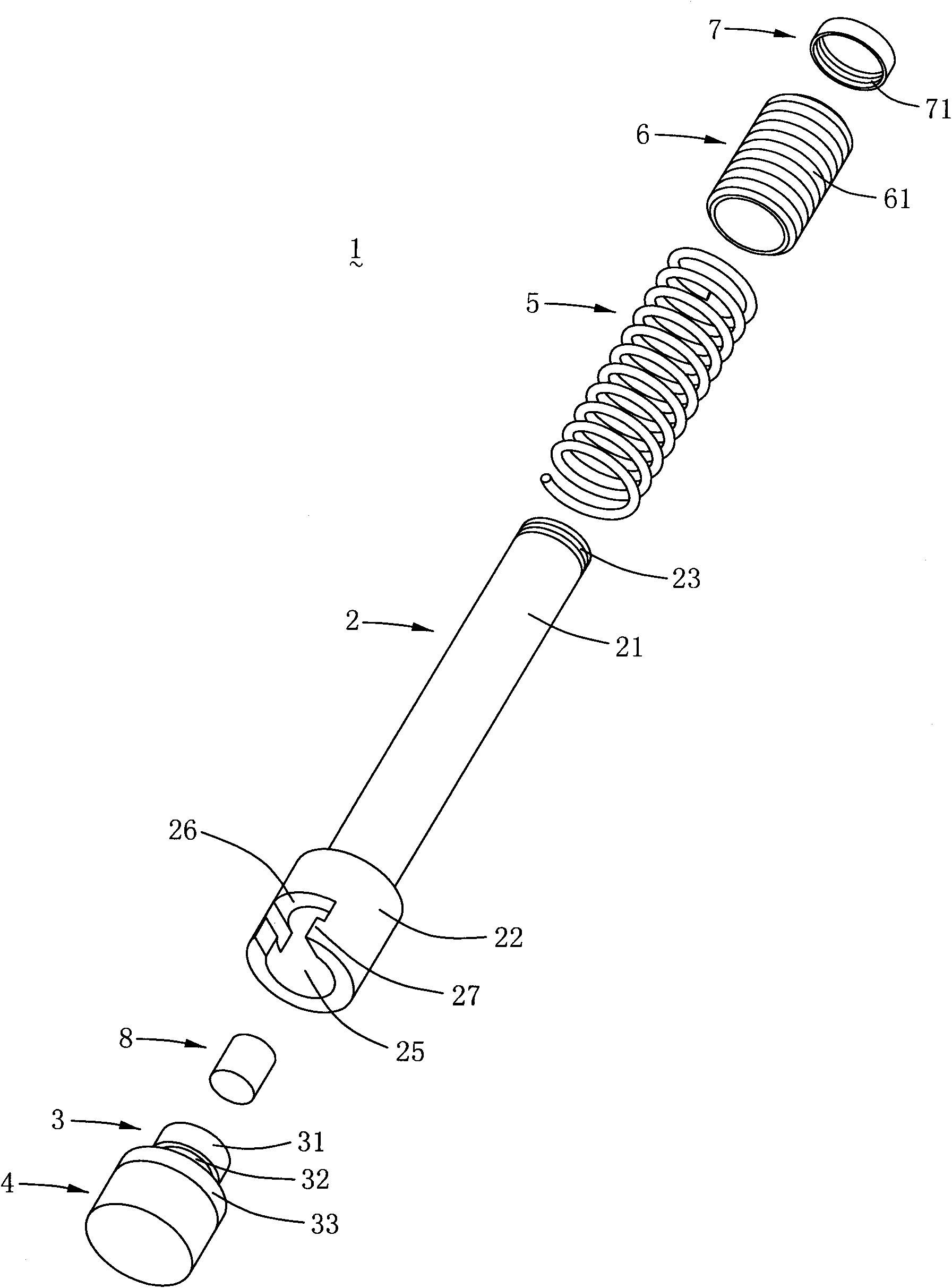

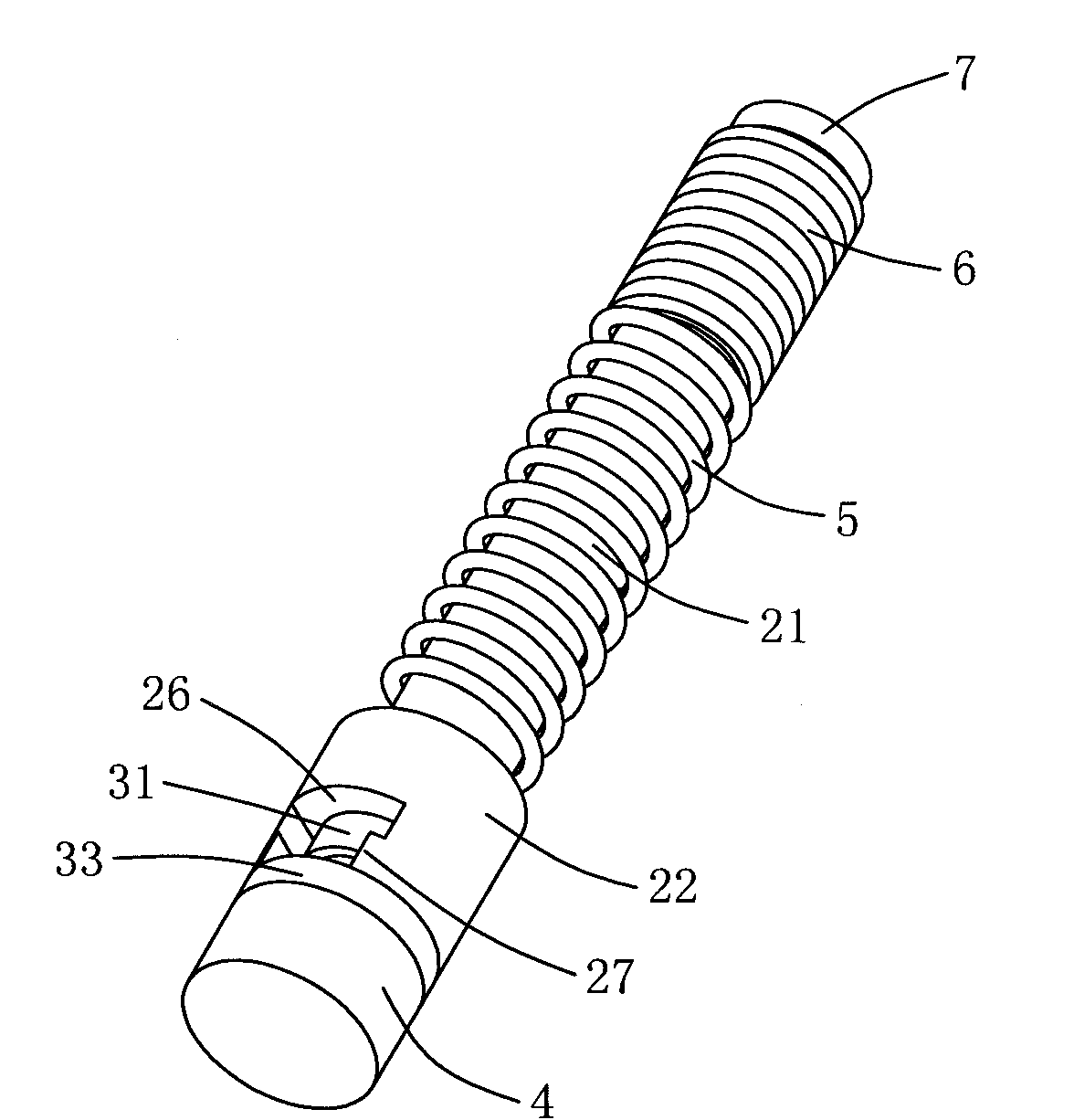

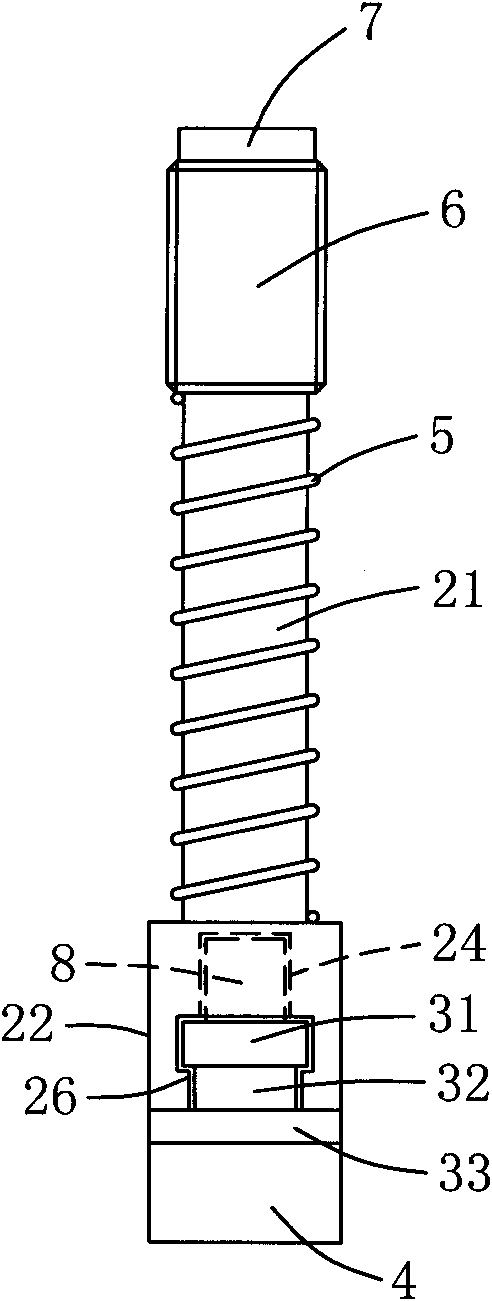

[0018] Hereinafter, the present invention will be described as exemplary preferred embodiments with reference to the accompanying drawings. The structures shown in the exemplary embodiments and diagrams are only preferred embodiments of the present invention, and do not fully represent the technical spirit of the present invention. In the following description, the same elements in different drawings will be denoted by the same reference numerals. In addition, the directional terms mentioned in the following descriptions, such as "upper", "lower", "inner", "outer", "top", "bottom", etc., are only used to refer to the directions in the attached drawings. Illustrative, not limiting of the invention. Also, in the following description, detailed explanations of known related functions and structures may be omitted to avoid unnecessarily obscuring the subject matter of the present invention.

[0019] Relevant detailed description and technical contents of the present invention ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com