Gas-liquid component high chamber-pressure large-range variable working condition combustor

A large-scale, variable-working-condition technology, applied to burners, lighting and heating equipment, etc., can solve problems such as low thrust, insufficient ability to change working conditions in a small range, low chamber pressure, etc., to achieve guaranteed cooling, good performance, and simplified structure and the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

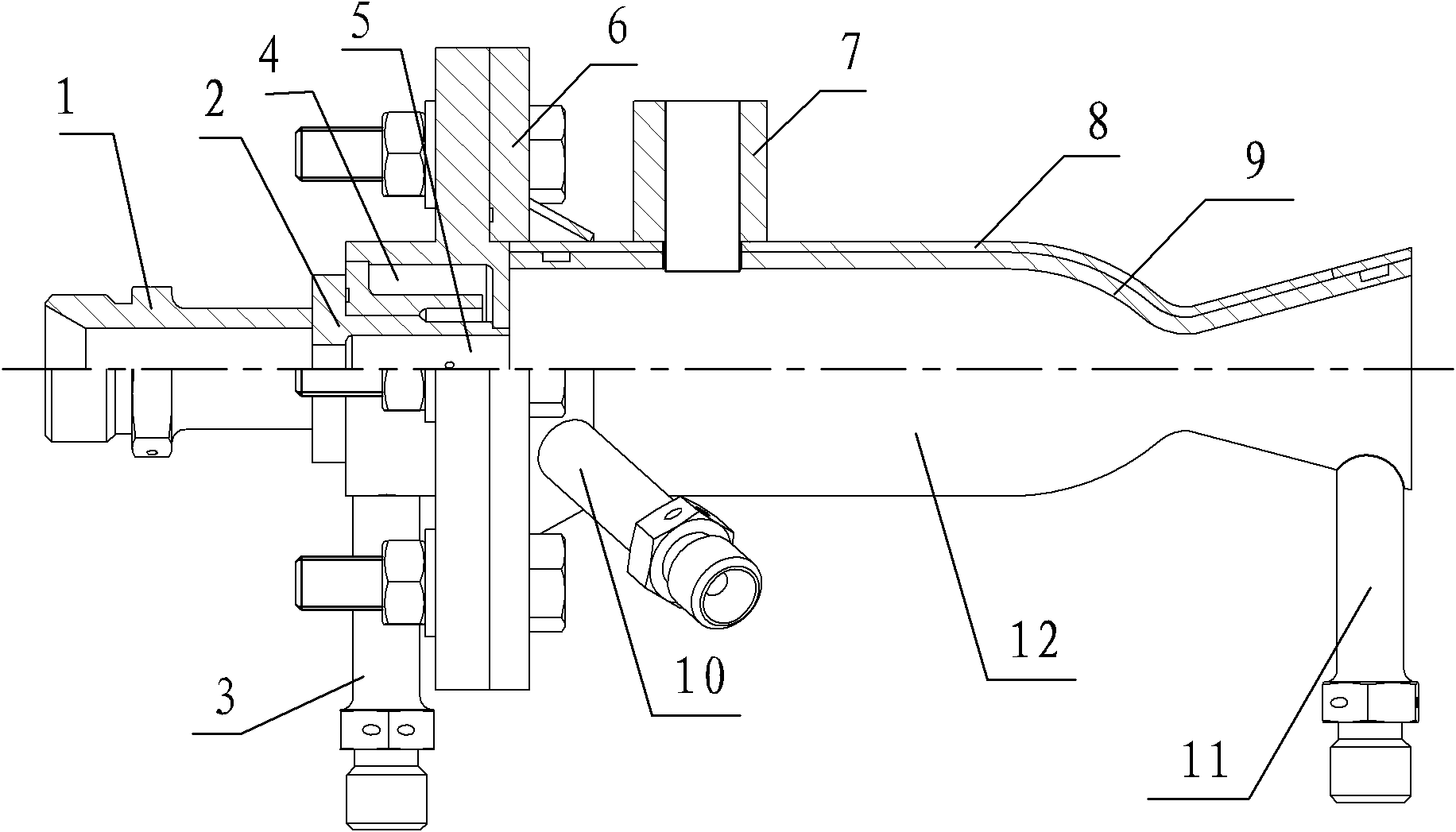

[0028] figure 1 Shown is a half-section structure diagram of a gas-liquid component high-chamber-pressure variable-range burner of the present invention, the burner is composed of an injector and a nozzle, and the injector and the nozzle are connected by a flange 6 . The volume of the oxidant liquid collection chamber formed by the oxidant inlet pipe 1 and the gas-liquid two-component nozzle 2 should be as small as possible. The baffles in the combustion chamber allow for increased combustion fluid velocity, thereby cooling the injector face plate.

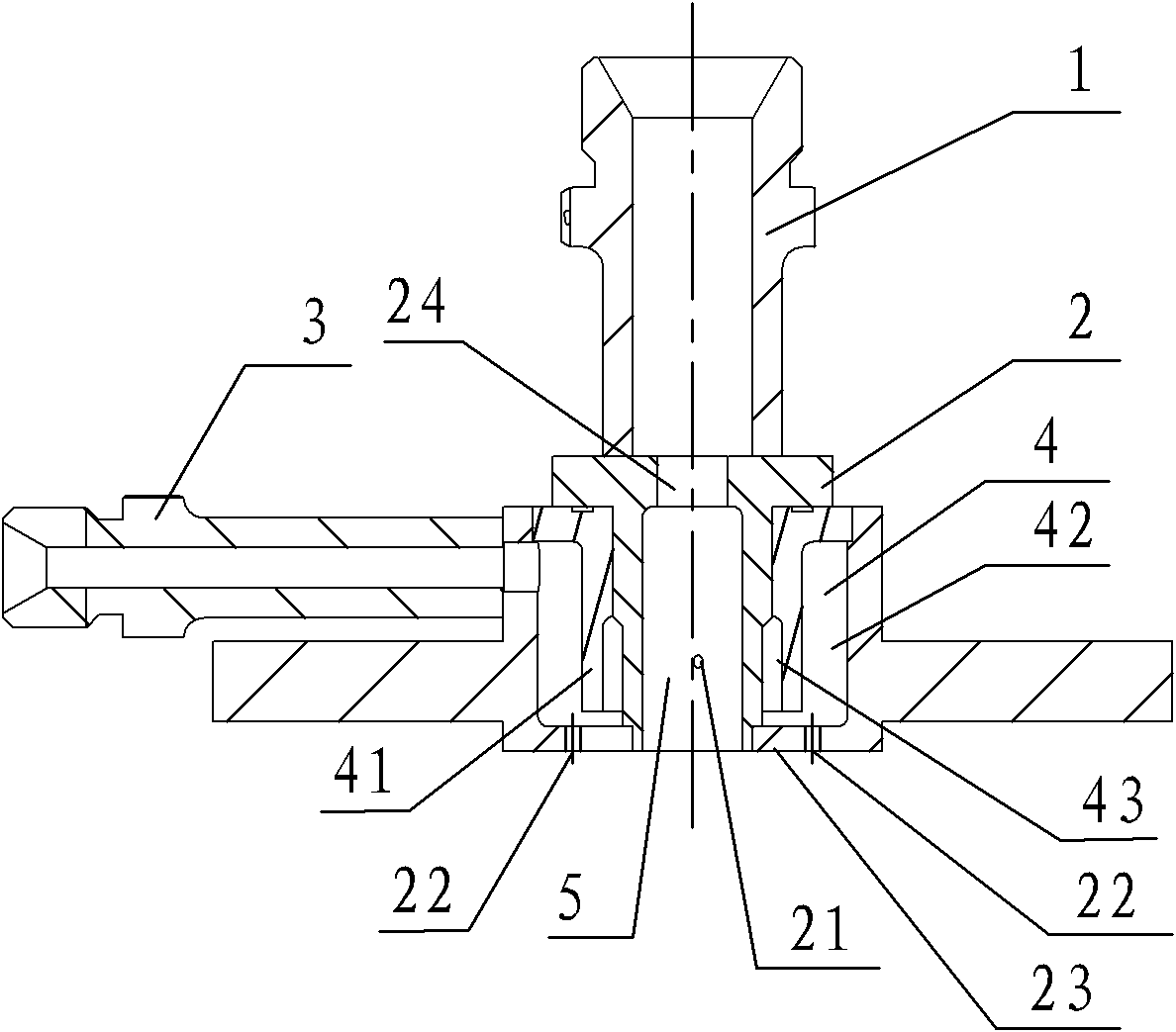

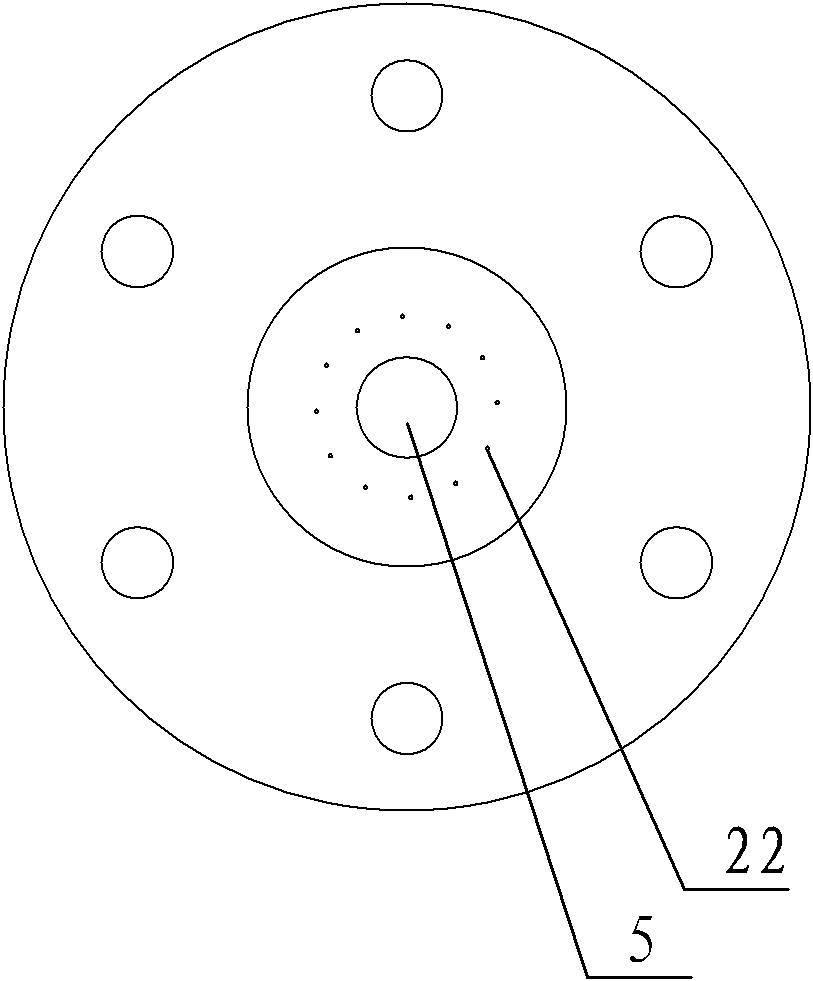

[0029] Such as figure 2 and image 3 As shown, the oxidant inlet pipe 1, the combustion agent inlet pipe 3, the gas-liquid dual-component nozzle 2, the injector panel 23 and the combustion agent chamber 4 form an injector, which includes an oxidant direct-flow nozzle 22, and three combustion agent nozzles. Self-strike direct-flow nozzle 21, twelve combustion agent direct-flow nozzles 5, and the circumference of combustion agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com