Method for preparing corrosion-resistant sintered neodymium iron boron (NdFeB) magnet

A NdFeB, corrosion-resistant technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem of corrosion resistance of high-performance sintered NdFeB magnets, low comprehensive performance of rare earth permanent magnets, etc. problems, to achieve the effects of reduced weight loss, satisfactory corrosion resistance, and strong electrochemical corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

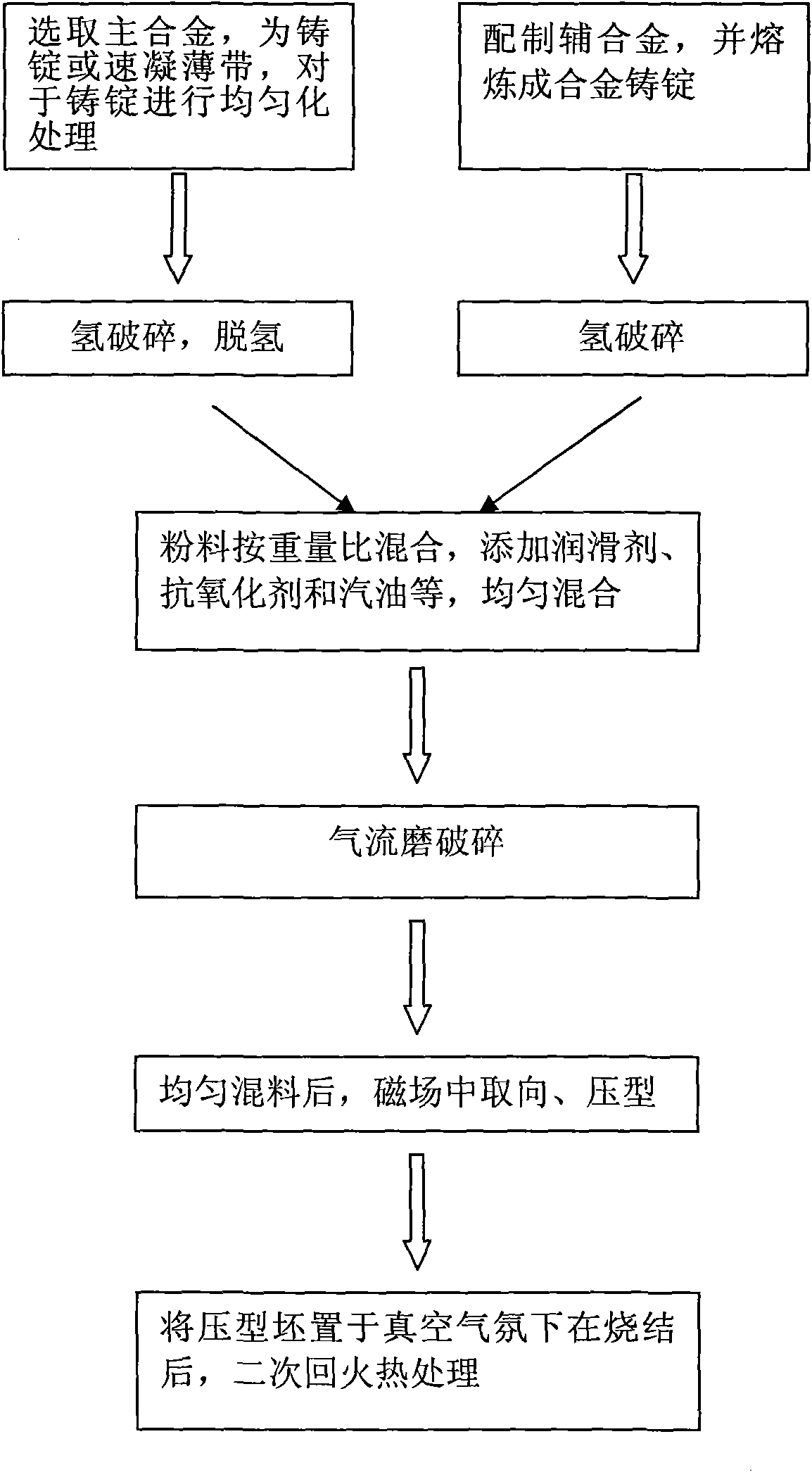

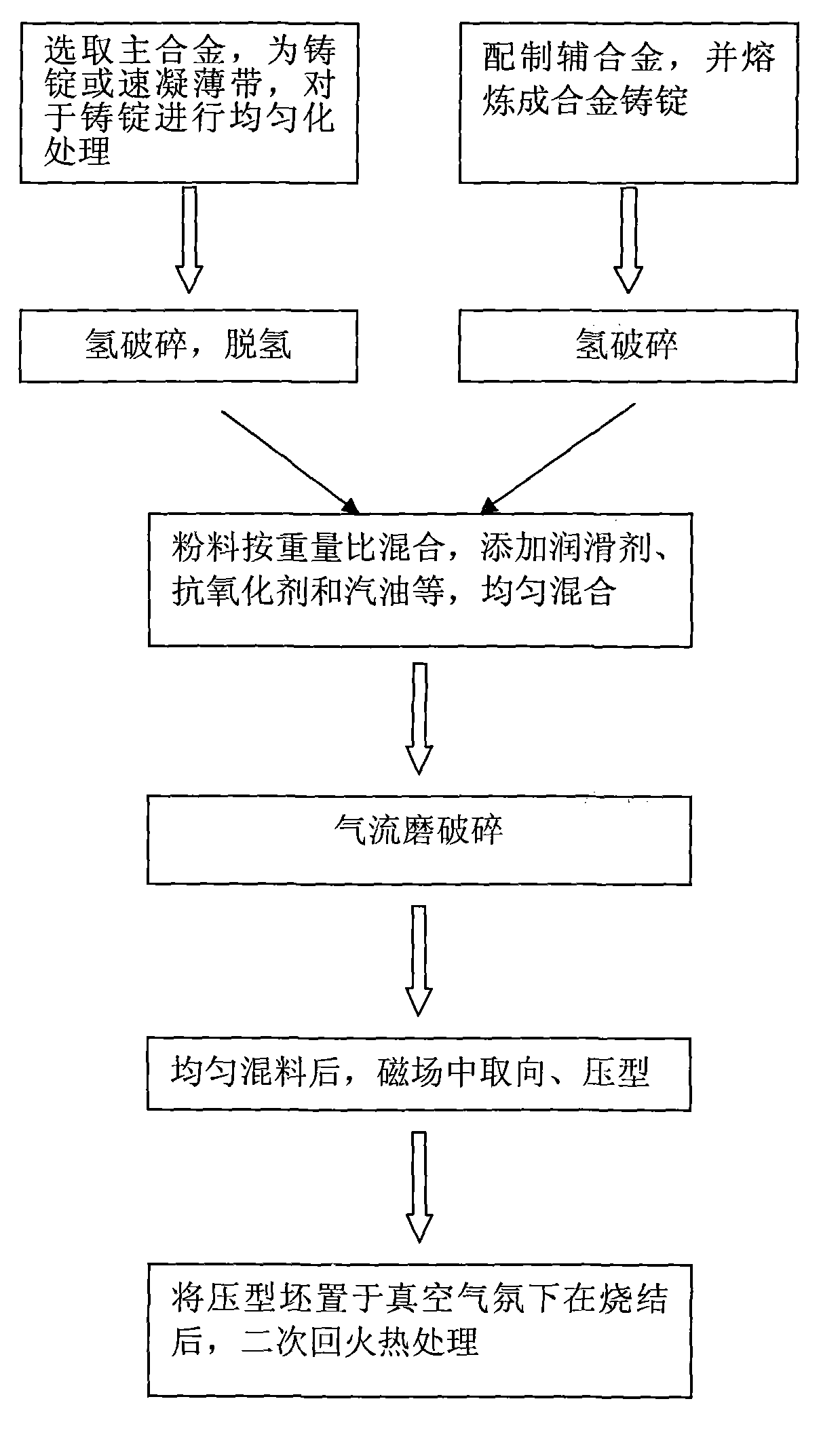

[0018] In conjunction with the accompanying drawings, a method for preparing a corrosion-resistant sintered NdFeB magnet of the present invention comprises the following steps:

[0019] Step 1, select the main alloy, the main alloy is the NdFeB alloy ingot made by casting process or the NdFeB quick-setting sheet made by the quick-setting sheet process, and the atomic ratio of its composition is close to Nd:Fe:B=2 : 14:1, the specific composition is adjusted according to the performance requirements; for the alloy ingot, the composition is homogenized at 1050-1150°C for 10-20h.

[0020] Step 2, preparation auxiliary alloy, the atomic percentage of auxiliary alloy is R1 100-x-y-z co x m y R2 z , where 25≤x≤60, 0≤y≤10, 0≤z≤10, R1 is one of Nd or Pr or a mixture of both, R2 is one of Dy, Tb or a mixture of both, M is one or a mixture of two or more of Al, Ga, Cu, Ti, Nb, Zr, and Hf.

[0021] Step 3. Under the protection of inert gas, the auxiliary alloy is melted in an interm...

Embodiment 1

[0029] A method for preparing a corrosion-resistant sintered NdFeB magnet, comprising the following steps:

[0030] Step 1. Select the main alloy as an alloy ingot. The atomic percentage composition of the main alloy is Nd: 11.0%, Dy: 1.0%, Tb: 0.5%, Nb: 0.1%, Al: 0.2%, Cu: 0.1%, Ga: 0.1 %, Fe: 81.0%, B: 6.0%, the main alloy ingot was homogenized at 1100°C for 20h.

[0031] Step 2, preparing auxiliary alloy, the atomic percentage composition of auxiliary alloy is Nd: 40.0%, Co: 60.0%.

[0032] In step 3, the auxiliary alloy is smelted by an induction melting method to obtain an auxiliary alloy ingot.

[0033] Step 4, the main and auxiliary alloys are respectively hydrogen crushed to make powder. Dehydrogenate the crushed main alloy at 550°C for 3h.

[0034] Step 5, mixing the main and auxiliary alloys after the hydrogen crushing treatment, the weight of the auxiliary alloy powder accounts for 5% of the total weight of the two, and simultaneously adds a lubricant accounting ...

Embodiment 2

[0040] A method for preparing a corrosion-resistant sintered NdFeB magnet, comprising the following steps:

[0041] Step 1. Select the main alloy as quick-setting flakes, and the atomic percentage composition of the main alloy is Nd: 7.2%, Pr: 0.5%, Dy: 2.2%, Tb: 0.9%, Co: 1.5%, Nb: 0.3%, Al: 0.3 %, Fe: 80.8%, B: 6.3%.

[0042] Step 2, preparing auxiliary alloy, the atomic percentage composition of auxiliary alloy is Nd: 30%, Pr: 25%, Dy: 1%, Co: 40%, Cu: 2%, Ga: 2%.

[0043] In step 3, the auxiliary alloy is smelted by an induction melting method to obtain an auxiliary alloy ingot.

[0044] Step 4, the main and auxiliary alloys are hydrogen crushed to make powder respectively, and the crushed main alloy is dehydrogenated at 500° C. for 4 hours.

[0045] Step 5, mixing the main and auxiliary alloys after the hydrogen crushing treatment, the weight of the auxiliary alloy powder accounts for 7% of the total weight of the two, and simultaneously adds 0.1% of the lubricant by we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com