Combined automatic stair-climbing fire-extinguishing smoke-discharging robot

A combined, smoke extractor technology, applied in instruments, motor vehicles, signal transmission systems, etc., can solve the problems of not having to climb stairs, small size and weight, complicated operation, etc., and achieve simple, safe and reliable operation, and simplified control. System and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

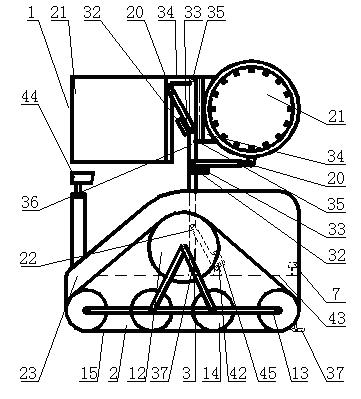

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

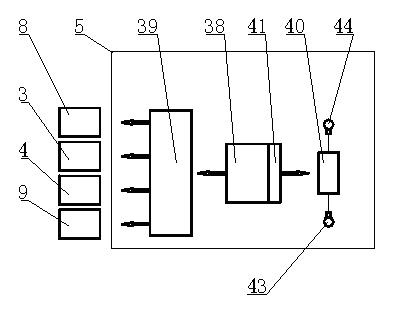

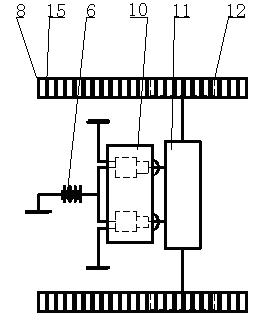

[0028] combine Figure 1-Figure 4 , The combined automatic stair-climbing fire-fighting and smoke-exhausting robot 1 of the present invention includes a crawler-type automatic walking chassis 2, a combined fire-fighting and smoke-exhausting device 3, an emergency spray self-protection device 4, a control and image transmission system 5, and a crawler-type automatic walking chassis 2 As a carrier, the combined fire-fighting and smoke exhaust device 3, the emergency jet self-protection device 4, the control and image transmission system 5 are installed on the crawler-type automatic walking chassis 2; the crawler-type automatic walking chassis 2 includes a battery pack 6, a supporting chassis 7, The crawler drive system 8 and the stability and anti-tipping mechanism 9 are installed on the support chassis 7 for the battery pack 6 that provides po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com