Numerical control system of grinding machine

A numerical control system and parameter technology, applied in the direction of grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of high production cost, damage and damage of machine tool parts, etc., to overcome the inconvenience of control and improve the human-computer interaction function , avoid complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

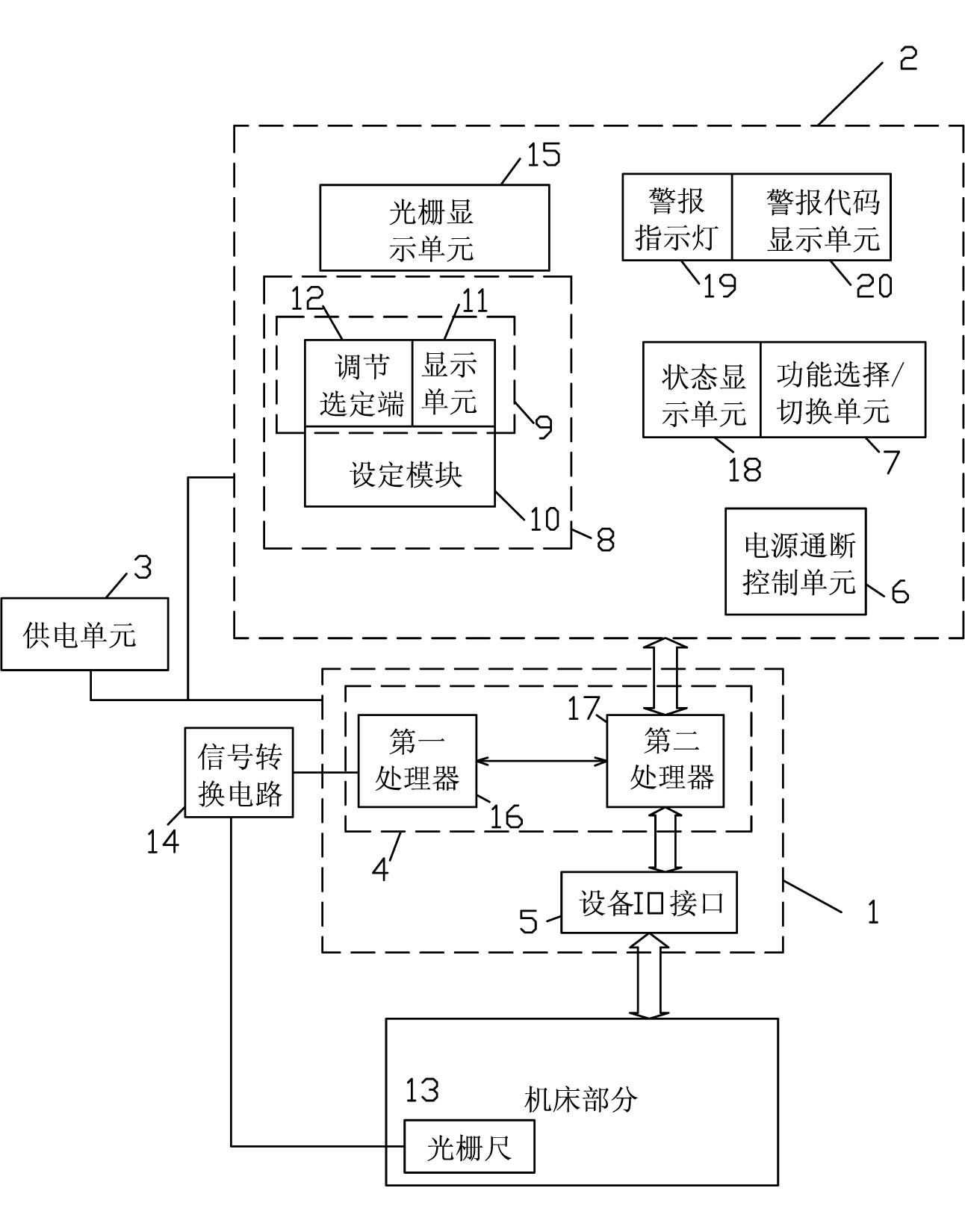

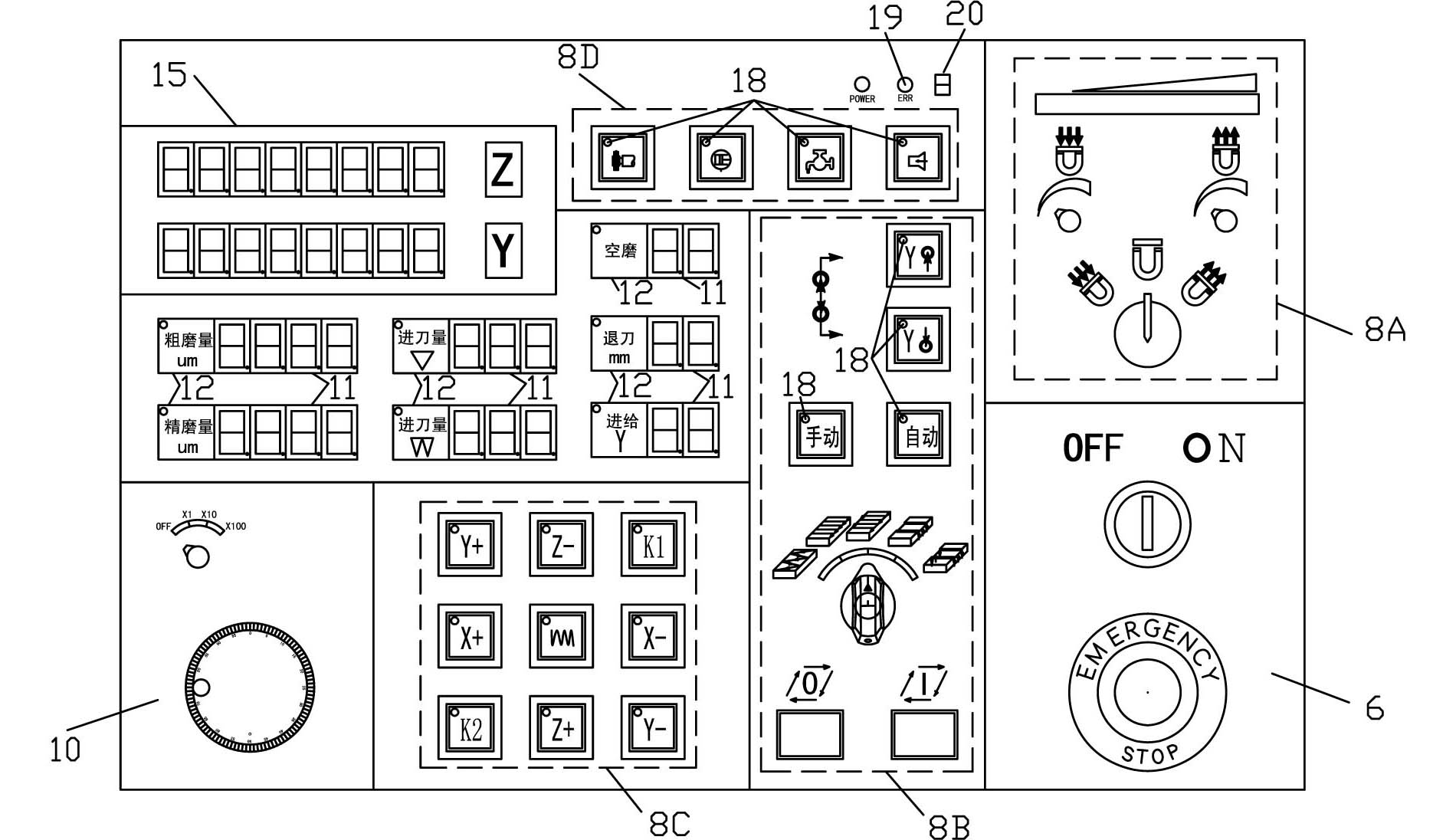

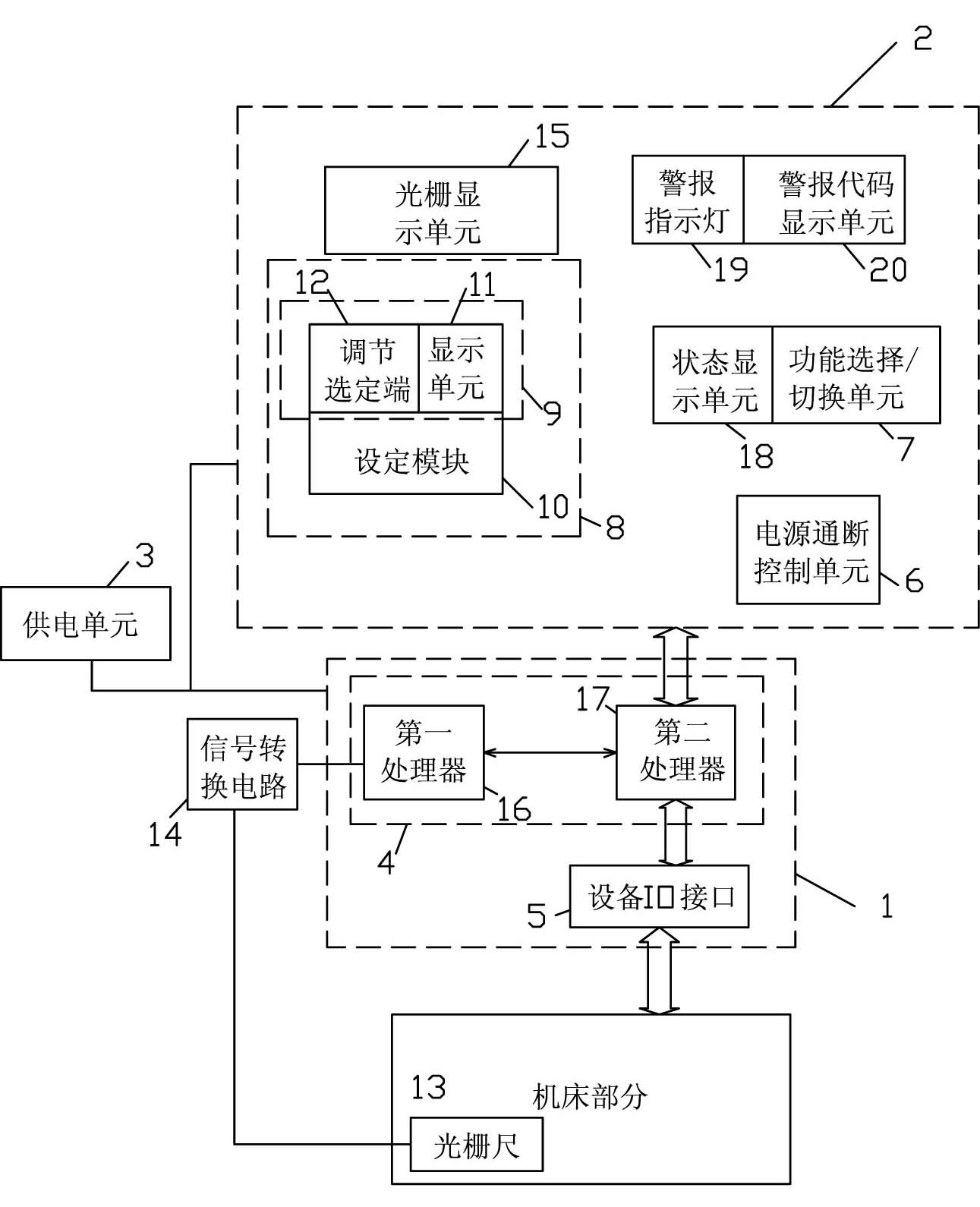

[0017] refer to figure 1 with figure 2 , a kind of grinding machine numerical control system of the present invention, comprises control unit 1, control panel 2 and power supply unit 3, the output end of described power supply unit 3 is connected with control unit 1 and control panel 2, and described control unit 1 comprises processing module 4 And equipment IO interface 5, the output terminal of described processing module 4 is connected with the control terminal of each equipment of grinding machine through equipment IO interface 5, and described control panel 2 is provided with power on-off control unit 6, function selection / switching unit 7 and parameter Interactive regulation unit 8 .

[0018] The power supply on-off control unit 6 is used to start or close the grinding machine complete machine, such as figure 2 As shown in the embodiment, when the key switch in the power on-off control unit 6 is rotated from the OFF position to the ON position, the whole machine is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com