High-frequency punching machine for tube body

A punching machine, high frequency technology, applied in metal processing and other directions, can solve the problems of patient pain, damage to patients' organs, troublesome operation of medical staff, etc., and achieve the effect of improving safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

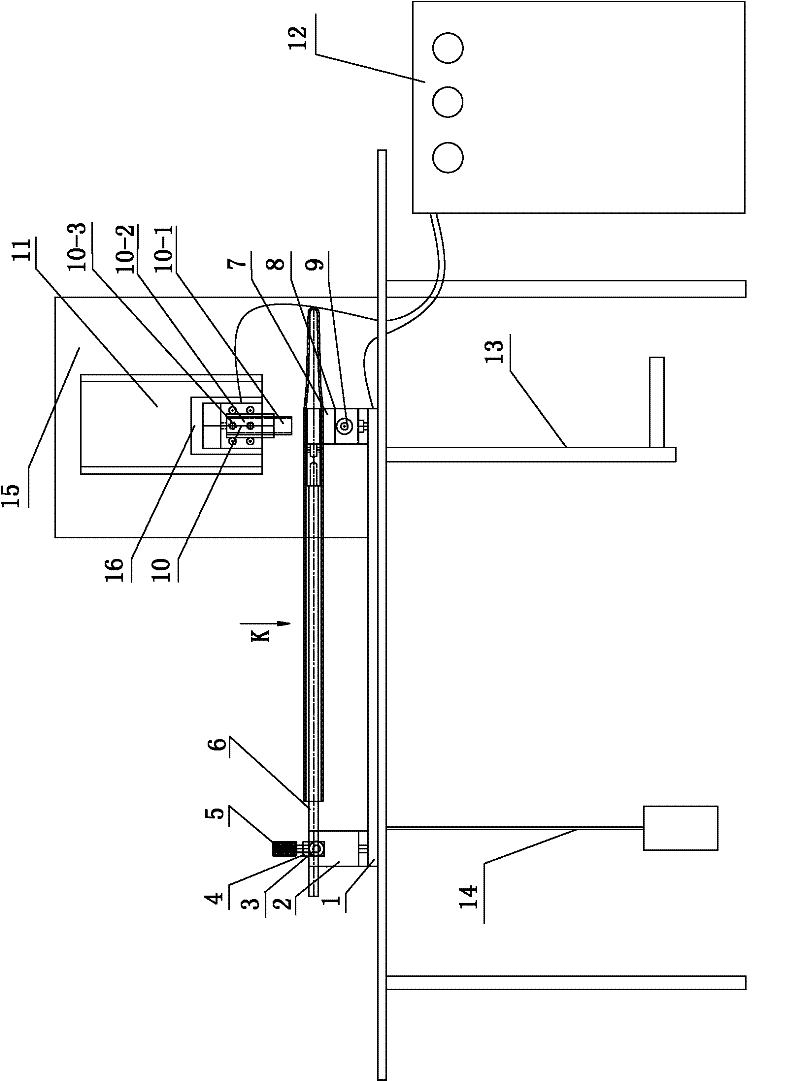

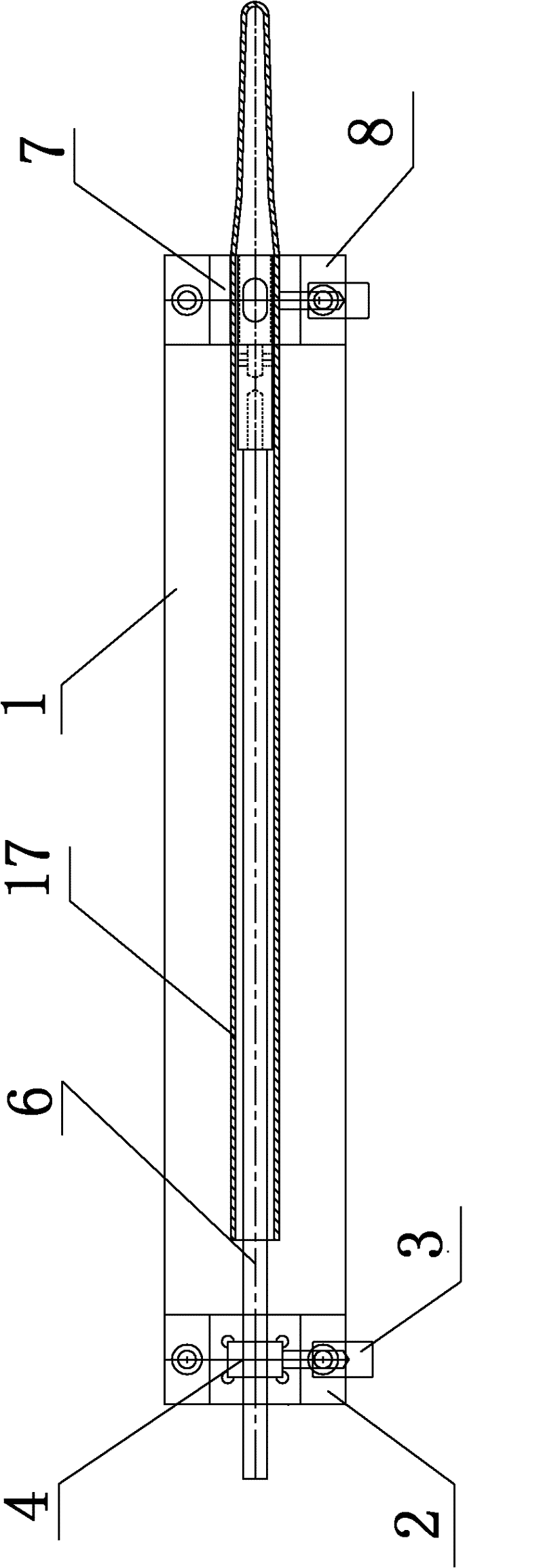

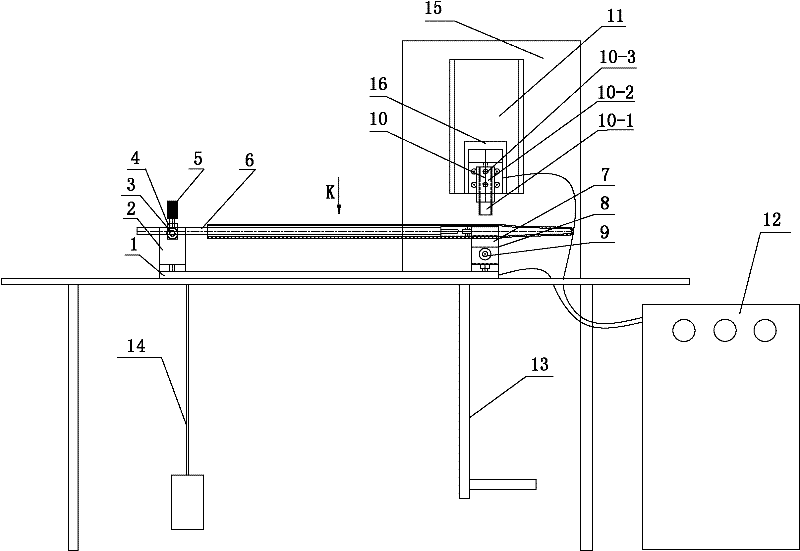

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0016] see figure 1 and figure 2 , a high-frequency punching machine for a pipe body, including a mounting base plate 1, an electrode rod 6, a punching punch assembly 10 and an electric control box 12, an electrode support frame 2 is fixed on one side of the mounting base plate 1, and an electrode support frame 2 is fixed on the other side The insulating support 7 is fixed by the support base 8 and the support fastening screw 9, and the upper end of the electrode support frame 2 is shaped on the installation groove for installing the electrode holder 4, and the electrode holder is fastened by the electrode holder screw 3 on the installation groove 4. The insulating support 7 is a polytetrafluoro insulating support, and the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com