Three-dimensional vibration stress relief multitask acquisition and control system and method thereof

A stress-relieving, three-dimensional vibration technology, applied in the direction of electrical program control, etc., can solve the problems of not fully reflecting the vibration of the workpiece, increasing the number of operators, single one-dimensional signal data, etc., to achieve complete signal, eliminate residual stress, and accurate results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

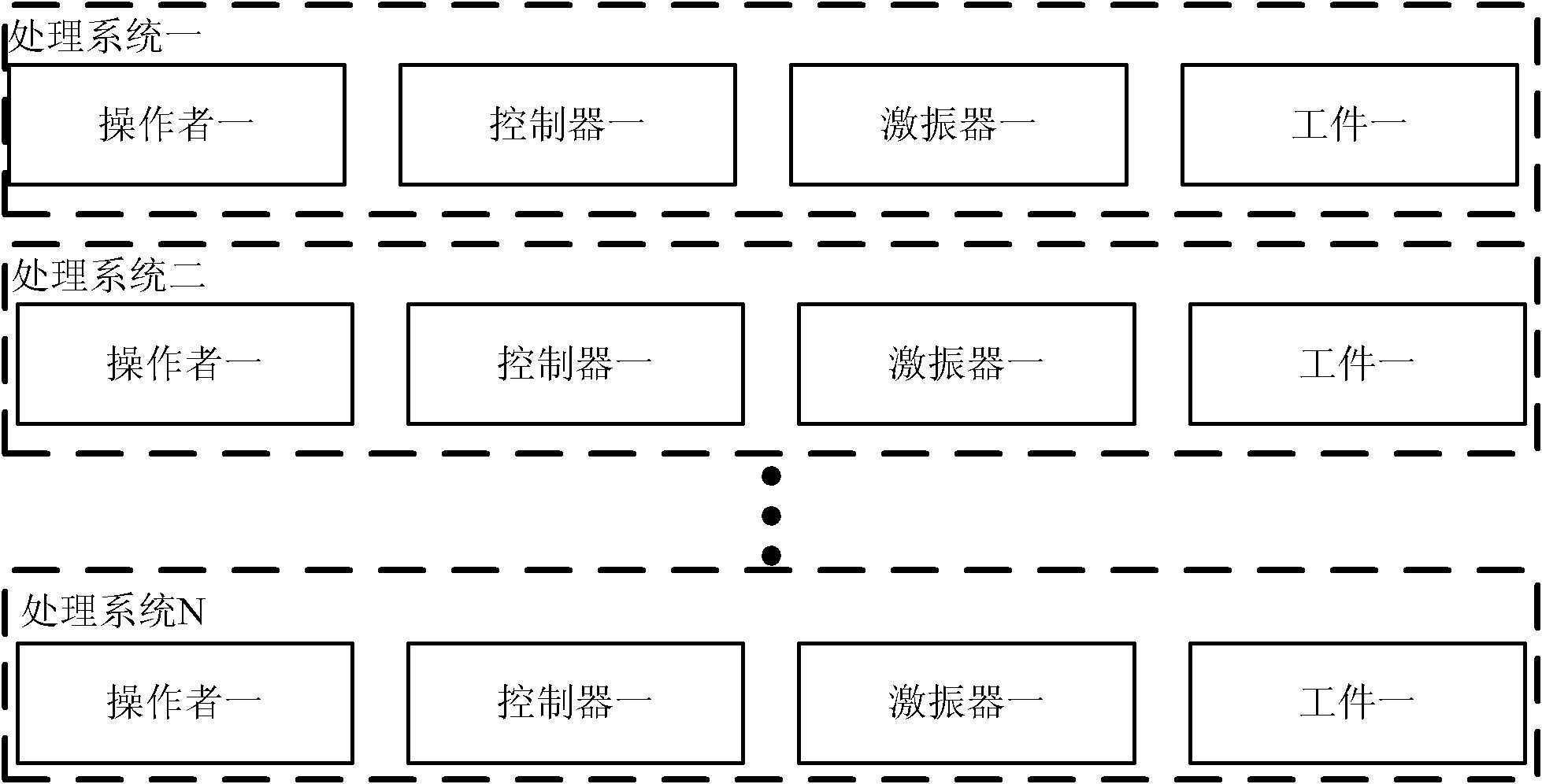

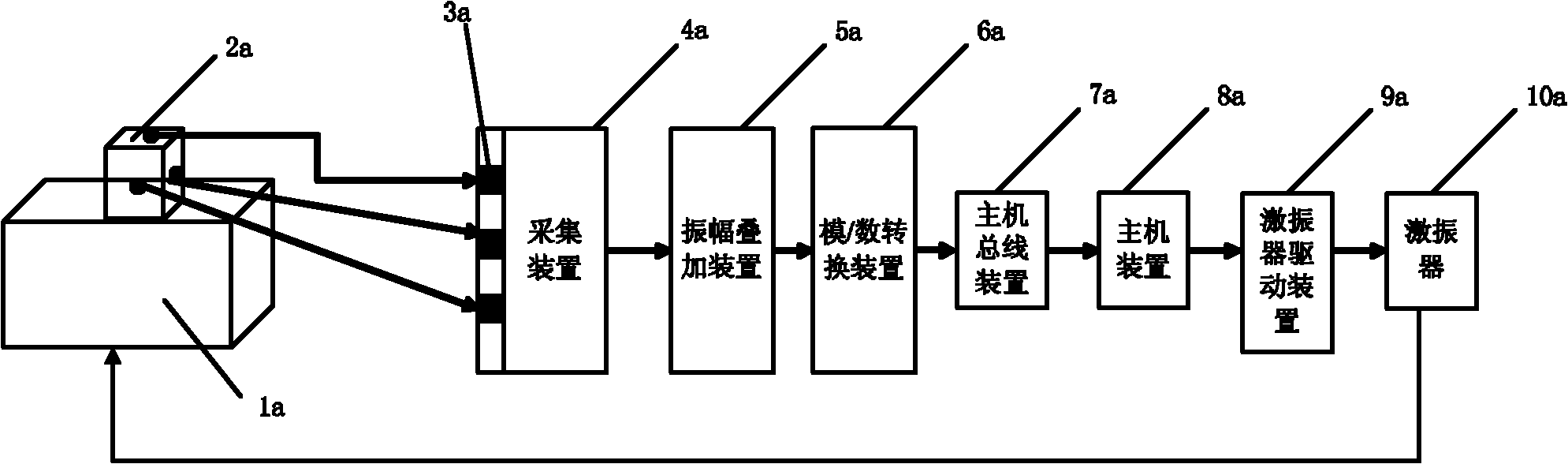

[0065] The implementation of the multi-task acquisition and control system and method for the three-dimensional vibration elimination stress of the present invention will be described in detail below in conjunction with the accompanying drawings.

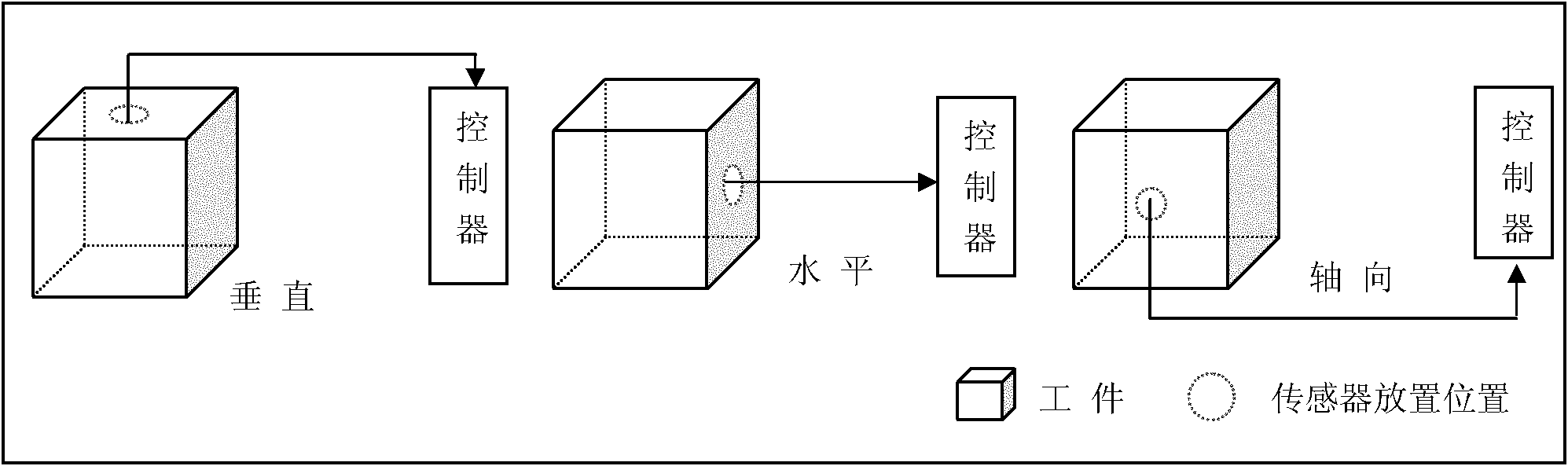

[0066] see image 3 The three-dimensional vibration elimination stress multi-task acquisition and control system of the present invention includes at least one workpiece 1a, a sensor 2a matching each workpiece 1a, and the sensor 2a is placed on the surface of the workpiece 1a, wherein the sensor 2a is a three-dimensional wired sensor, such as Qinhuangdao Jiameng YD300 from Measurement and Control Technology Company, or other types of alternative three-dimensional wired sensors, the three interfaces of sensor 2a are respectively connected to the circuit board port 3a built in the host ISA or PCI bus through low-noise cables, and sensor 2a is placed away from the excitation At the clamping position of the vibrator 10a, the host device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com