Method and device for controlling multi-level coagulation bath concentration for spinning polyacrylonitrile protofilament

A technology of polyacrylonitrile and coagulation bath, which is applied in wet spinning, single-component synthetic polymer rayon, textiles and papermaking, etc. It can solve the problems of unfavorable high-performance PAN precursor and difficulty in realizing precise control of coagulation bath concentration, etc. , to achieve the effect of convenient operation, overcoming operational errors and stable performance

Inactive Publication Date: 2011-02-09

ZHEJIANG TAIXIAN NEW MATERIAL

View PDF5 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, at present, there are few reports on the control method of the concentration of the PAN precursor spinning coagulation bath

If the method of manually adding water to the coagulation tank is used to control the concentration of coagulation baths at all levels, it is difficult to achieve precise control of the concentration of coagulation baths due to human error, which is not conducive to the production of stable high-performance PAN precursors

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

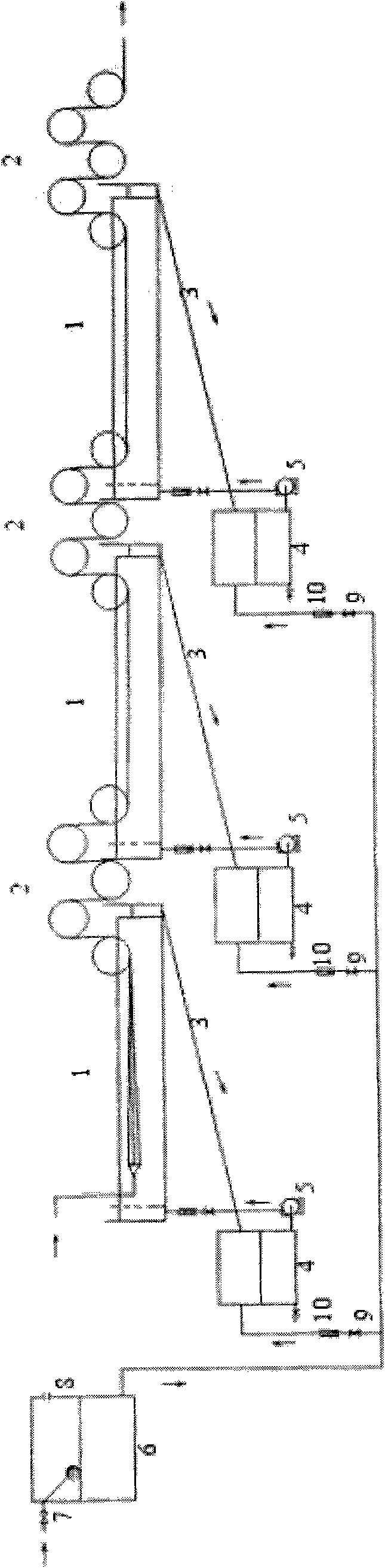

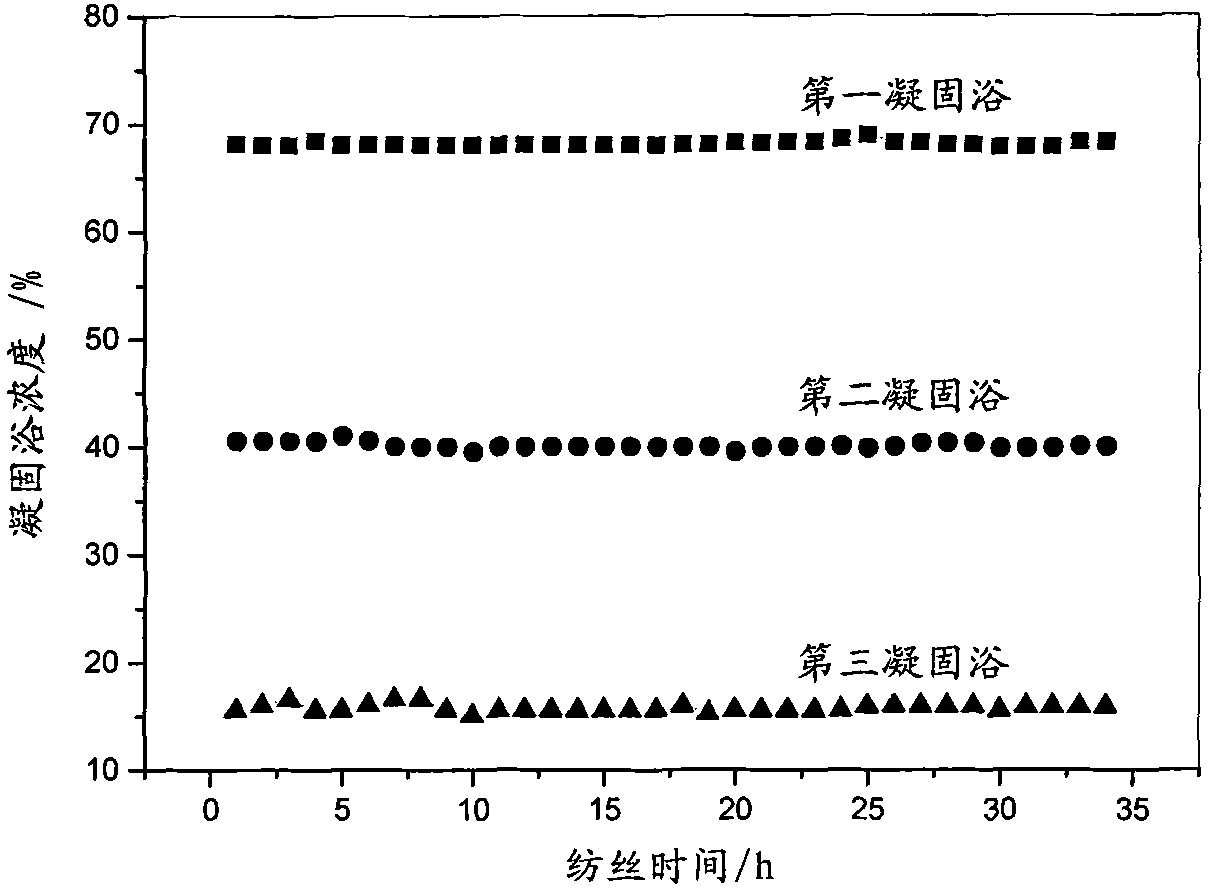

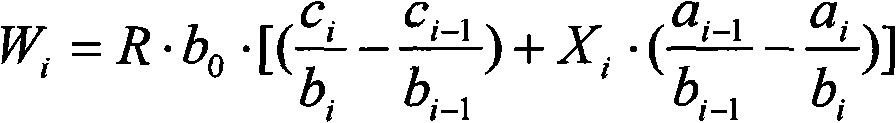

The invention discloses a method and a device of multi-level coagulation bath concentration for spinning polyacrylonitrile protofilament. An automatic water-supplementing device is arranged in a coagulation bath at each level, and the concentration of each coagulation bath at each level is controlled by adjusting the water-supplementing speed of the automatic water-supplementing device. The water-supplementing speed is based on a the theory that the amount of supplemented water is equal to the sum of water which is purely brought by filaments out of the coagulation bath and water needed for diluting a good solvent released by the filaments from the coagulation bath to the concentration of the coagulation bath. Compared with the prior art, the invention has the advantages of convenient operation and simple equipment, overcomes operation errors brought by artificial intermittent water supplementation and can accurately control the coagulation bath concentration at each level so as to favorably produce stable high-performance polyacrylonitrile protofilament.

Description

technical field [0001] The invention relates to the technical field of spinning polyacrylonitrile precursors, in particular to a multistage coagulation bath concentration control method and device for spinning polyacrylonitrile precursors. Background technique [0002] Carbon fiber has many excellent properties such as low density, high specific strength, high specific modulus, high temperature resistance and corrosion resistance, and has been widely used in various fields of aerospace, national defense and civilian industries. According to the raw material route, carbon fiber can be divided into three types: polyacrylonitrile (PAN)-based, pitch-based and viscose-based. Among them, PAN-based carbon fiber has become a carbon fiber with the fastest development, the highest output, the most varieties and the widest application due to its simple production process, low production cost and excellent mechanical properties. [0003] It is well known that high-performance PAN precu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D01F6/18D01D5/06

Inventor 欧阳琴陈友汜莫高明马洪波徐敏君严庆

Owner ZHEJIANG TAIXIAN NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com