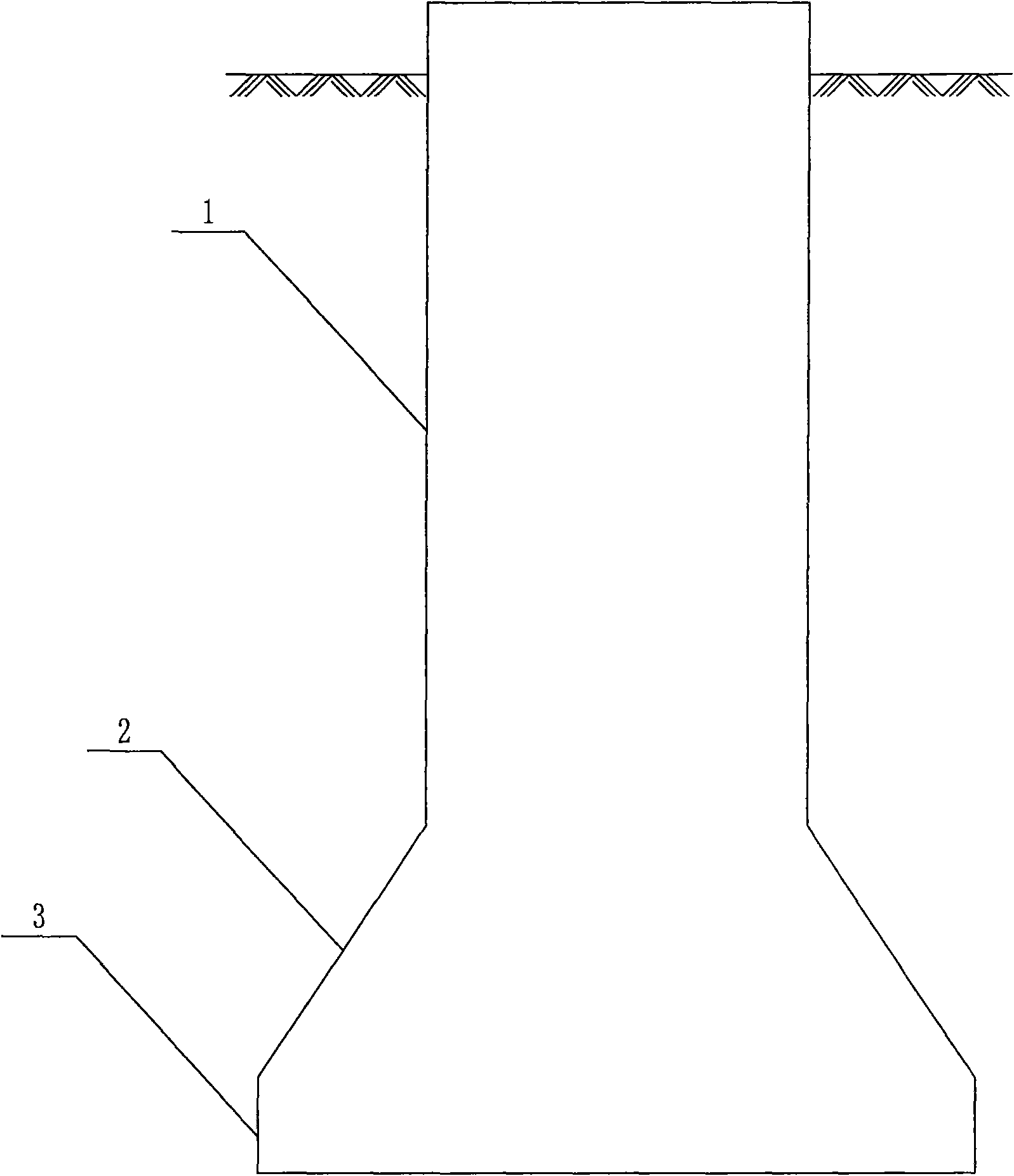

Dug pile foundation construction method

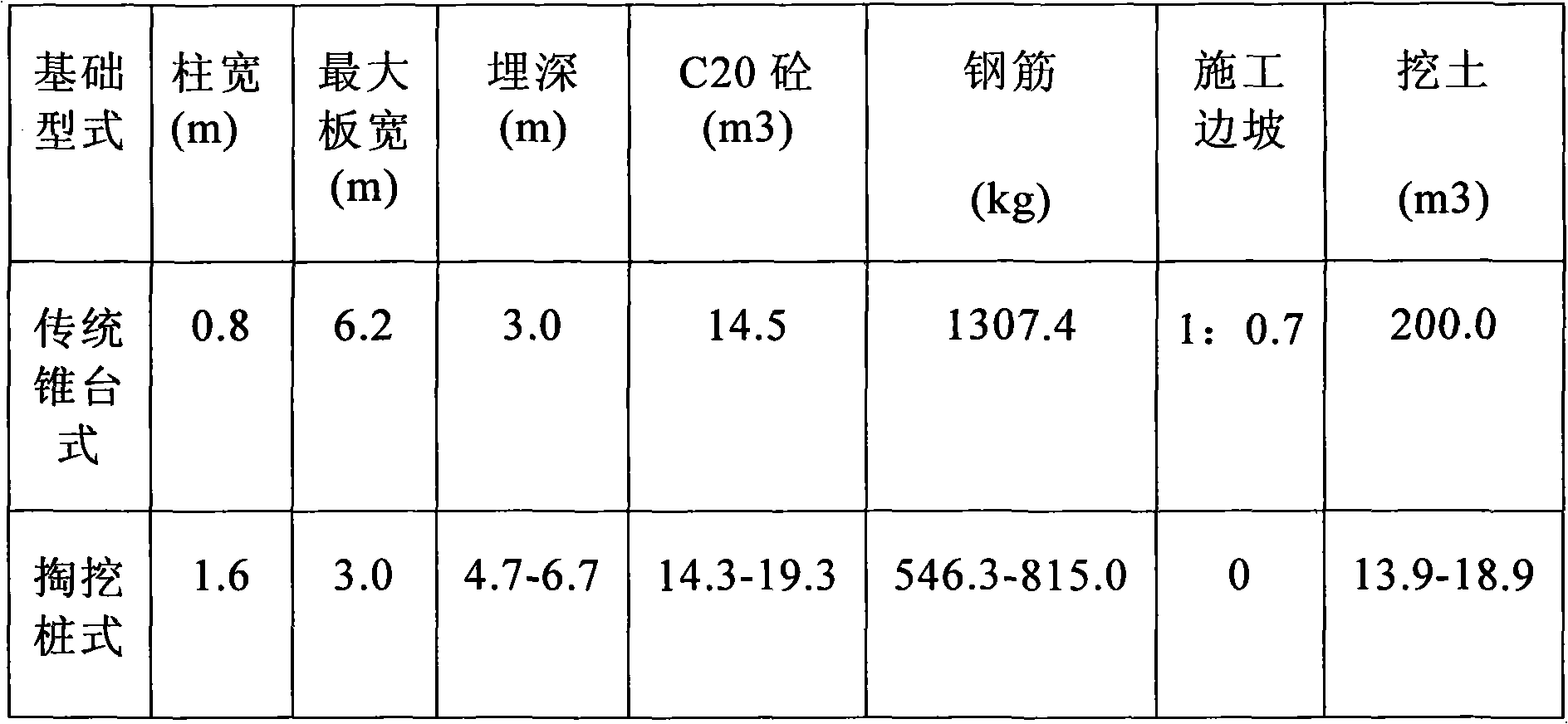

A construction method and pile foundation technology, which can be used in foundation structure engineering, excavation, construction, etc., can solve problems such as damage to the surface, poor foundation soil bearing capacity, soil erosion, etc., and achieve the effect of saving construction costs and improving bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] When digging and excavating pile foundation construction, first dig the hole according to the position and size of the pile foundation. The size of the hole should be convenient for at least one person to go up and down and construct. The hole is hammered and compacted on the edge of the mouth. Then the aperture limit is built to a certain height, so as to prevent the earth and stone from collapsing and the aperture from rolling into the hole, preferably the aperture limit can be built 0.3 meters high. Then dig a deep hole downwards, and dig the hole down to the depth required by the pile foundation. Choose suitable tools according to the soil quality. Generally, use a short shovel to dig the soil. Shallow blastholes are drilled, a small amount of explosives are loaded, and directional blasting is carried out. It should be noted that the live rock at the edge of the hole should be stripped and removed, and the hole wall should not be damaged by blasting, and cracks are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com