Oil tank level transmitting device

An oil storage tank, liquid level technology, applied in the direction of the liquid level indicator for the measurement of physical variables, etc., can solve the problems of difficulty in ensuring stability and reliability, the sensitivity of the liquid level sensor is discounted, and the measurement accuracy cannot be guaranteed. Good elastic deformation, easy repair and maintenance, high pressure sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

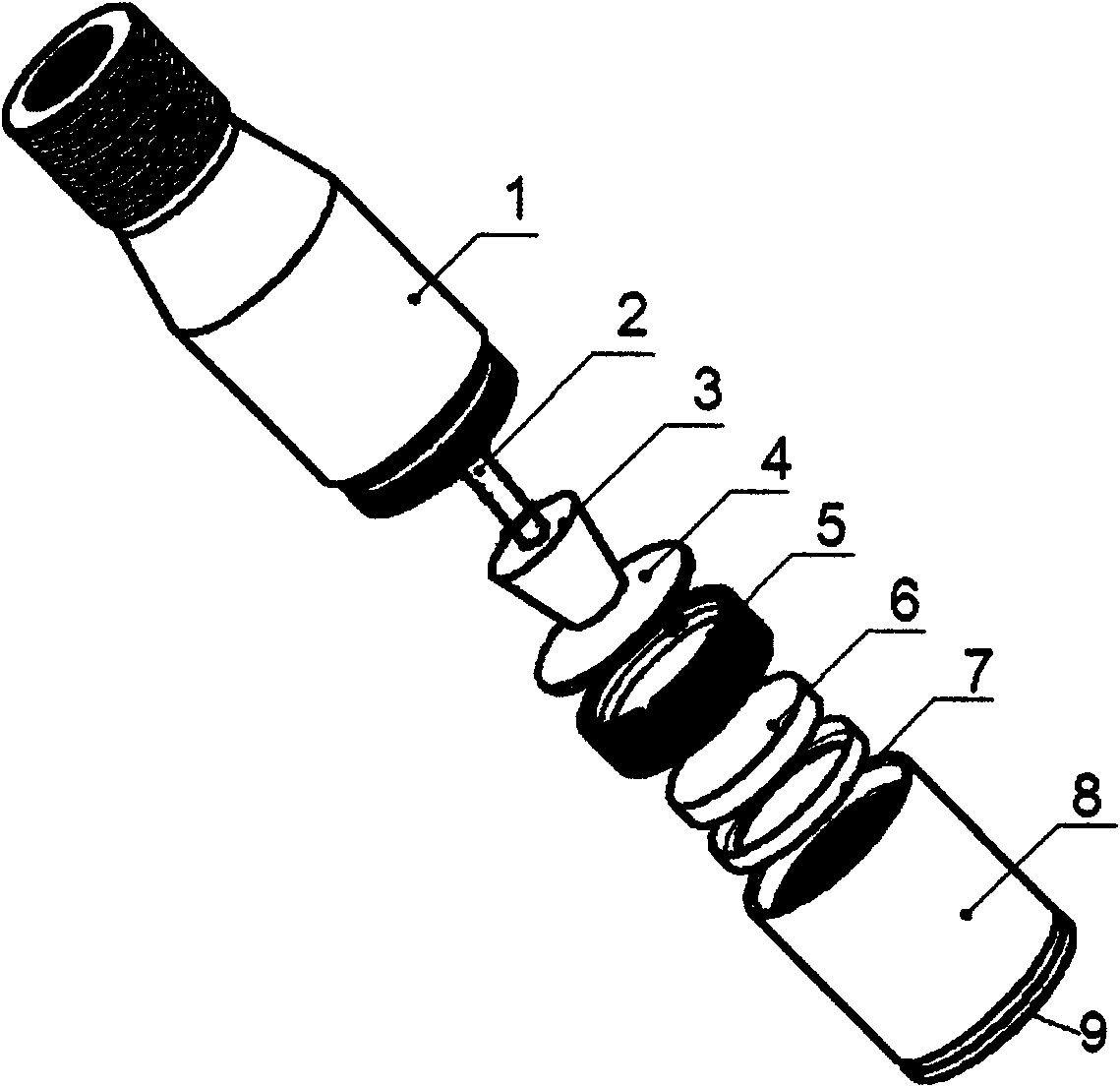

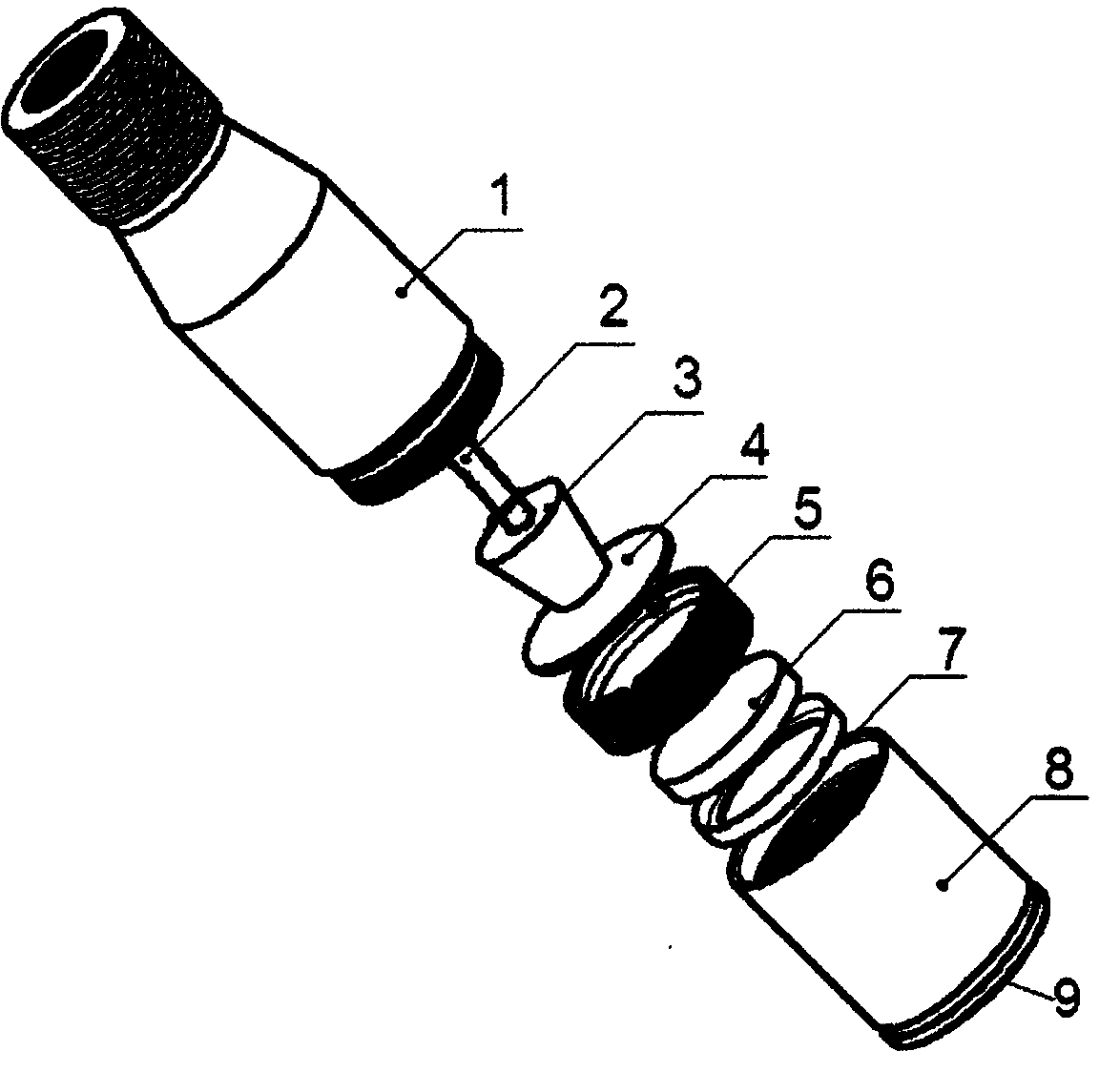

[0015] see figure 1 and figure 2 , the cylindrical sealing sleeve is composed of an upper cover 1 and a base 8, wherein the upper cover 1 and the base 8 are fixedly connected through threads (or buckles), the port of the base 8 is provided with a window 9, and the window 9 is provided with a sensor part.

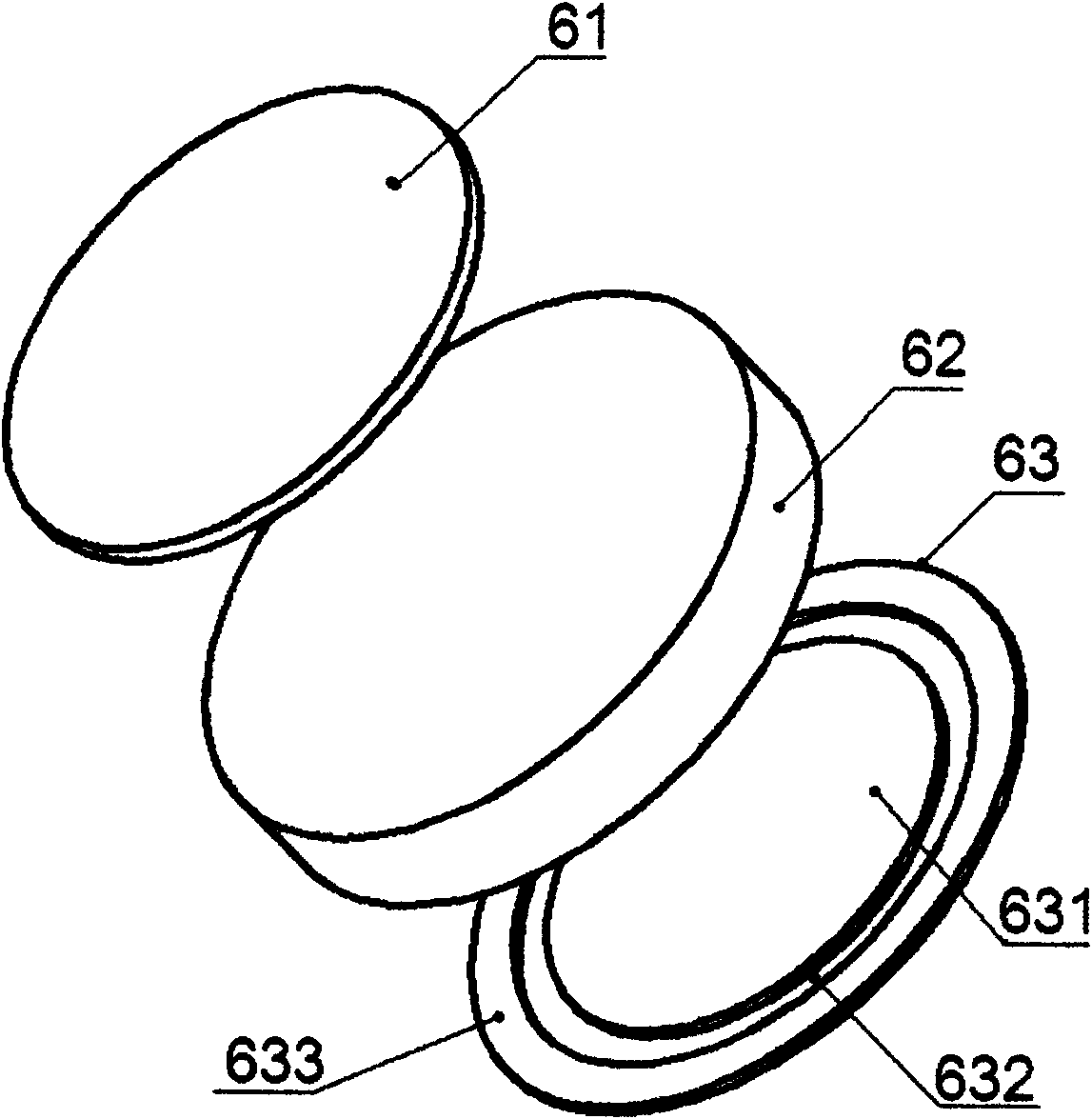

[0016] The sensing component is a capacitive pressure sensing component 6, which is composed of an electrically connected capacity voltage converter 61, a flat capacitor upper plate 62 and a flat capacitor lower plate 63; wherein, the capacitor upper plate 62 is Thickness is the ceramic plate of 55mm (can be selected between 50~60mm), and the lower electrode plate 63 of the capacitor is a common electrode, and it is 0.6mm (can be selected between 0.5~0.65mm) with the thickness of composite layer on one side. Composed of ceramic plates, wherein the ceramic plates as the upper plate 62 of the capacitor and the lower plate 63 of the capacitor are all aluminum oxide (AL 2 o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com