Process for producing resin composition with partial-discharge resistance, resin composition with partial-discharge resistance, and insulating material with partial-discharge resistance

A technology of resin composition and manufacturing method, which is applied in the direction of plastic/resin/wax insulators, organic insulators, printed circuits, etc., can solve the problems of light weight of high-voltage equipment, low degradation tolerance, and slow degradation of insulating layers, etc., Achieve excellent partial discharge resistance and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

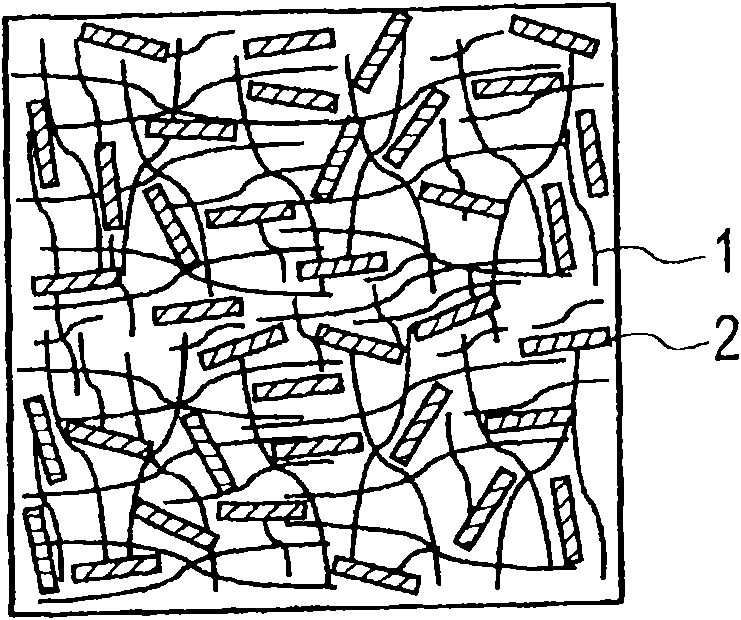

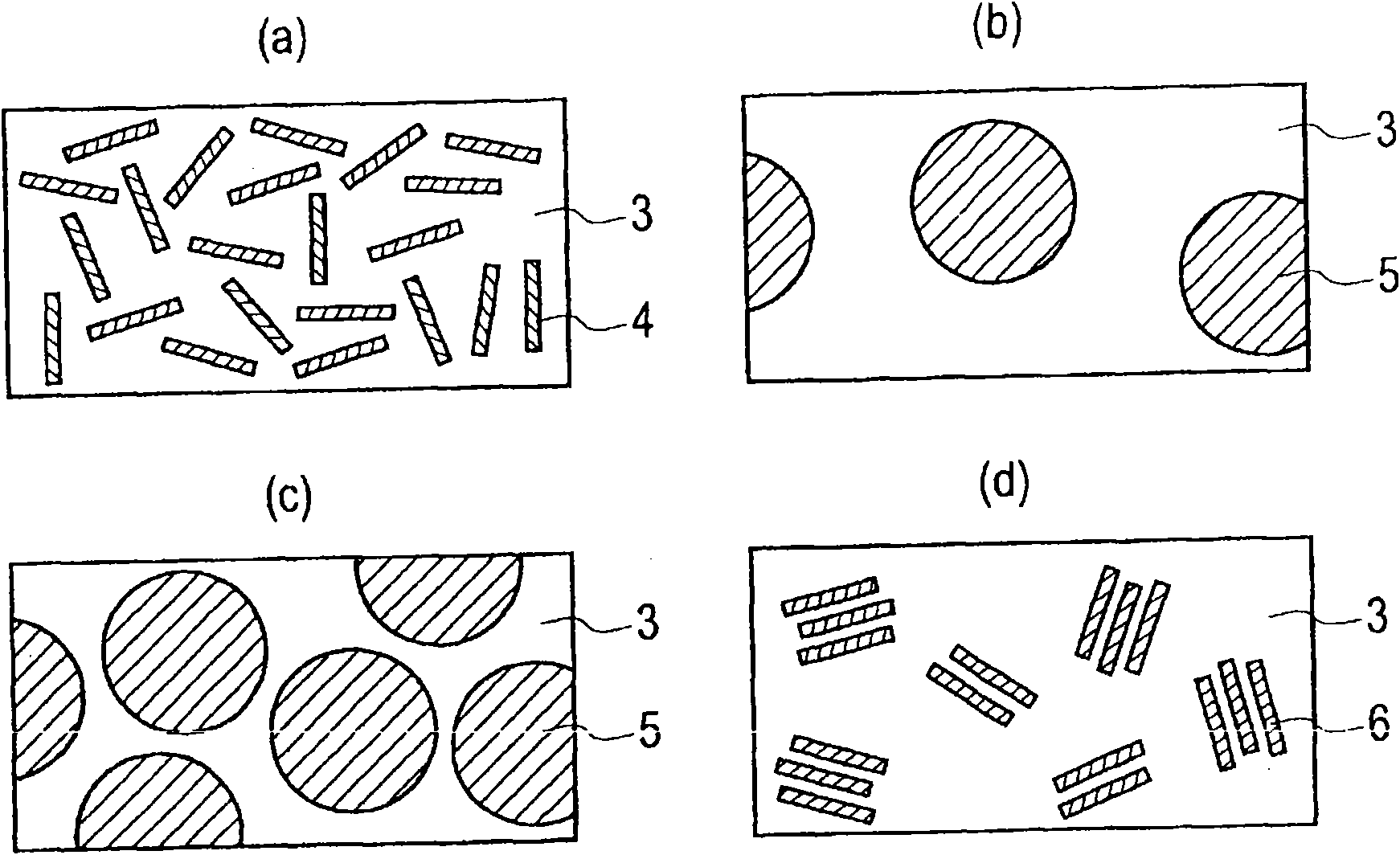

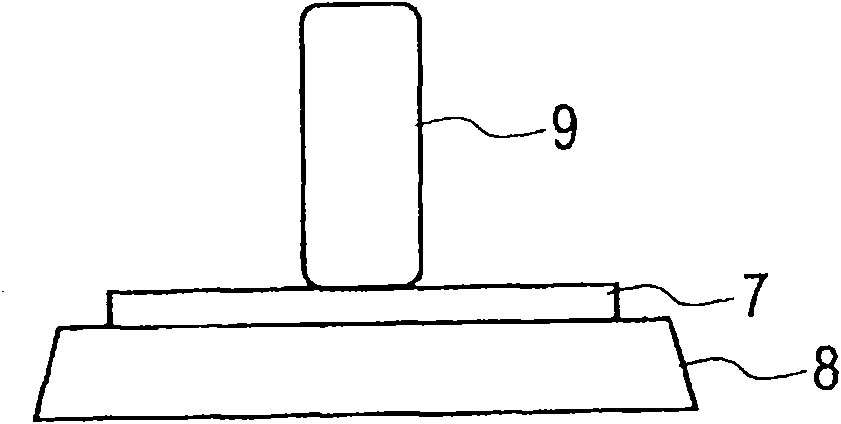

Method used

Image

Examples

Embodiment 1

[0062] Between the layers of layered clay minerals (manufactured by Kunime Industry Co., Ltd., trade name: Kunipia F), octadecylamine (manufactured by Lion Akuzo Co., Ltd., trade name: Amine) is inserted by intercalation treatment. 10 parts by weight of the substance of 18D) was added to 50 parts by weight of dimethylacetamide, and after stirring to make it swell, bisphenol A type epoxy resin (manufactured by Japan Epoxy Resin Co., Ltd., trade name: Epicoat 828) was added. After pre-mixing 100 parts by weight, kneading was performed at high shear using a three-roll mill. The kneaded product was washed with a large amount of distilled water to remove dimethylacetamide, and then the remaining distilled water was removed by drying under reduced pressure to obtain a kneaded product of an epoxy resin in which inorganic nanoparticles were uniformly dispersed. To this kneaded product, 86 parts by weight of an acid anhydride curing agent for epoxy resin (manufactured by Shin Nippon Ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com