Method for efficiently enriching high-quality hydroxyl tyrosol from olive leaves

A technology for olive leaf hydroxytyrosol and hydroxytyrosol is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., and can solve problems such as environmental pollution, general technicalities, poor selection of raw materials, etc. The effect of high rate and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

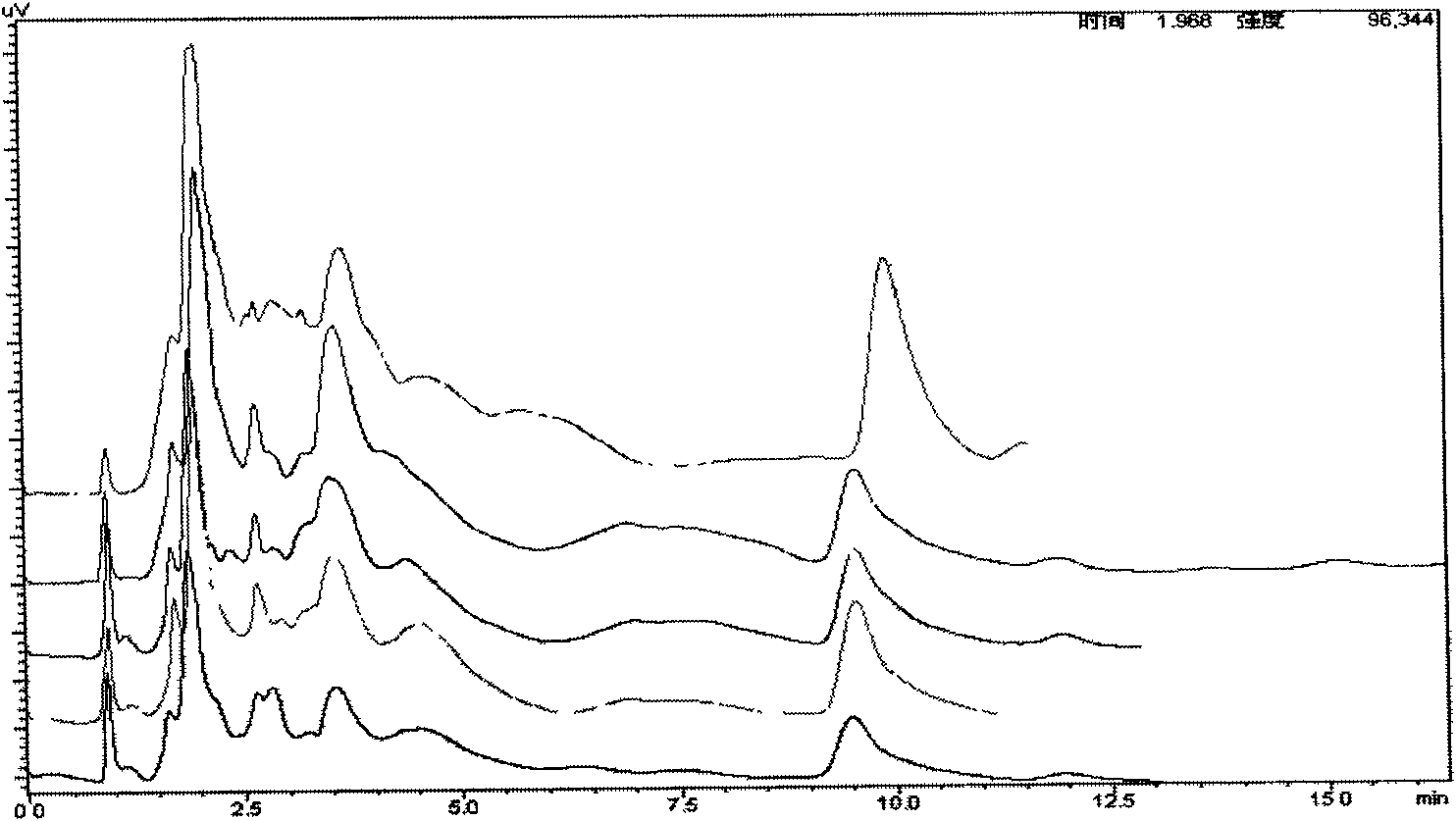

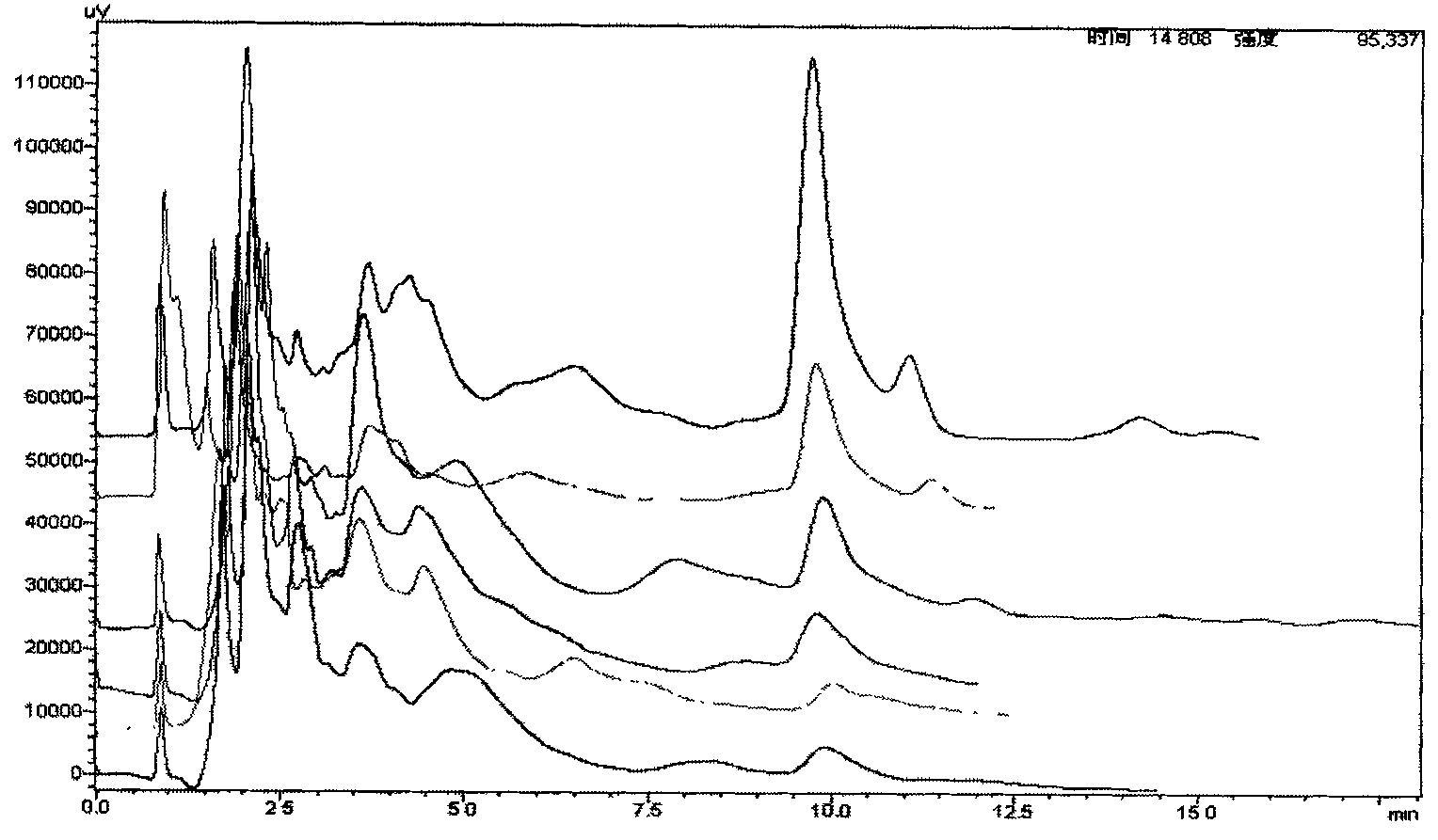

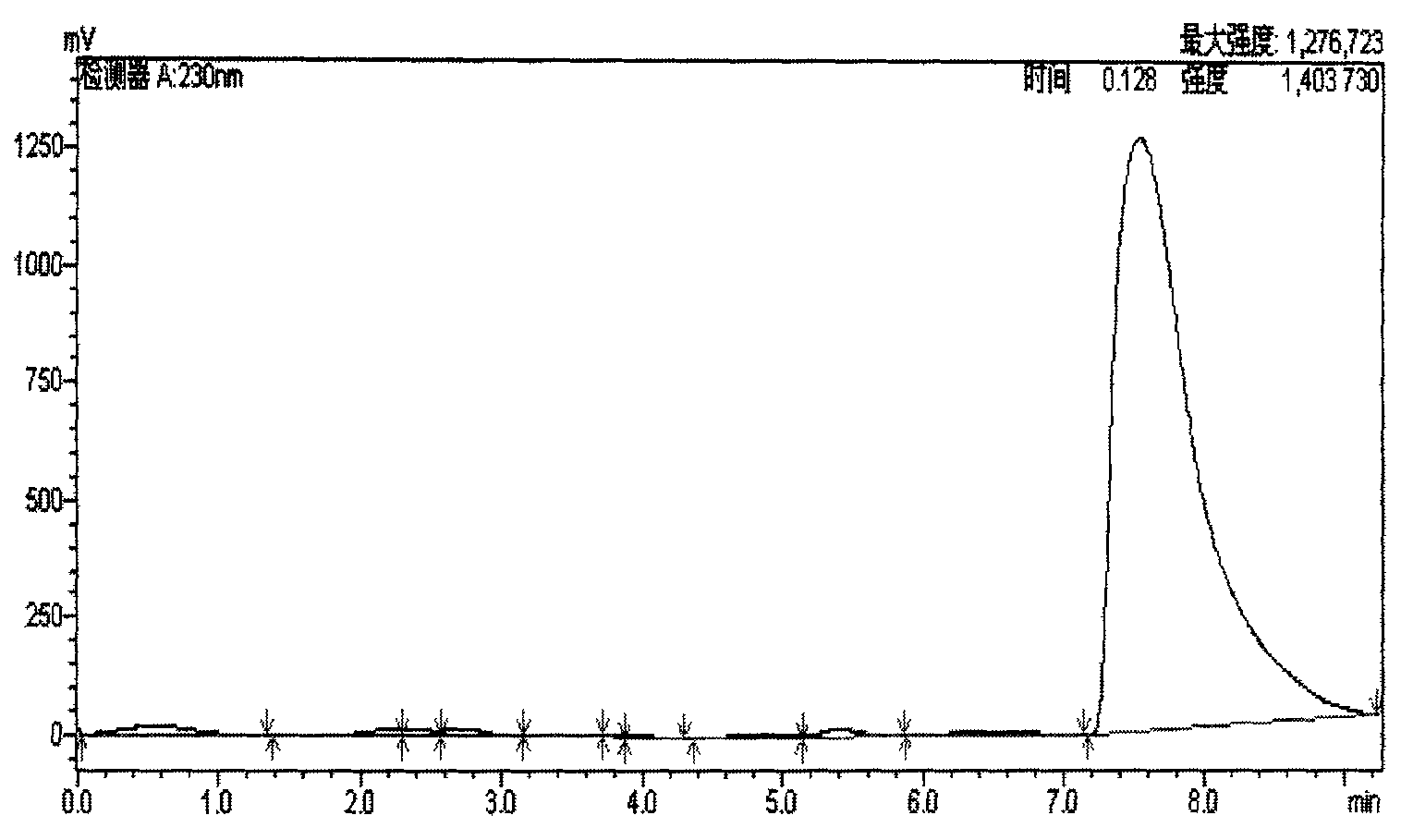

Image

Examples

Embodiment 1

[0051] (1) the olive leaves are dried at low temperature and protected from light, and pulverized;

[0052] (2) Get the crushed olive leaves and use ultrasonic extraction, the ethanol consumption is 1-30 times, the alcohol concentration is 30-100%, the leaching temperature is 25-65 ℃, the leaching time is 10-30min, and the leaching times are three times;

[0053] (3) Filter the leachate, concentrate in vacuum, and the vacuum concentration temperature does not exceed 65° C. to obtain crude olive leaf extract. Dilute the crude extract with water and filter to remove impurities;

[0054] (4) In step (3), the crude product of the olive leaf alcohol extract obtained in further carries out ion exchange separation, and the method comprises the following steps:

[0055] a wet packed column, diameter = 2cm, height = 15cm, 30g AB-8;

[0056] b Dissolve the sample and add it to the chromatographic column of a;

[0057] c Add eluent, first wash with 2-3 times the volume of water, then...

Embodiment 2

[0063] (1) the olive leaves are dried at low temperature and protected from light, and pulverized;

[0064] (2) Get the crushed olive leaves and use ultrasonic extraction, the ethanol consumption is 1-30 times, the alcohol concentration is 30-100%, the leaching temperature is 25-65 ℃, the leaching time is 10-30min, and the leaching times are three times;

[0065] (3) Filter the leachate, concentrate in vacuum, and the vacuum concentration temperature does not exceed 65° C. to obtain crude olive leaf extract. Dilute the crude extract with water and filter to remove impurities;

[0066] (4) In step (3), the crude product of the olive leaf alcohol extract obtained in further carries out ion exchange separation, and the method comprises the following steps:

[0067] a Wet packed column, diameter = 2cm, height = 15cm, 30g DM130;

[0068] b Dissolve the sample and add it to the chromatographic column of a;

[0069] c Add eluent, first wash with 2-3 times the volume of water, the...

Embodiment 3

[0075] (1) the olive leaves are dried at low temperature and protected from light, and pulverized;

[0076] (2) Get the crushed olive leaves and use ultrasonic extraction, the ethanol consumption is 1-30 times, the alcohol concentration is 30-100%, the leaching temperature is 25-65 ℃, the leaching time is 10-30min, and the leaching times are three times;

[0077](3) Filter the leachate, concentrate in vacuum, and the vacuum concentration temperature does not exceed 65° C. to obtain crude olive leaf extract. Dilute the crude extract with water and filter to remove impurities;

[0078] (4) In step (3), the crude product of the olive leaf alcohol extract obtained in further carries out ion exchange separation, and the method comprises the following steps:

[0079] a Wet packed column, diameter = 2cm, height = 15cm, 30g D101;

[0080] b Dissolve the sample and add it to the chromatographic column of a;

[0081] c Add eluent, first wash with 2-3 times the volume of water, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com