Control method for implementing microstructure by non quenched and tempered steel hot forging formation

A technology of non-quenched and tempered steel and microstructure, applied in the field of forging and forming, can solve the problems of unsuitable development cycle and cost control requirements, high development cost, long trial production time, etc., and achieve the effect of shortening process trial production time and avoiding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] Take the non-quenched and tempered steel automobile piston as an example, the material is 38MnVS6(Ti).

[0037] (1) Through the thermal simulation compression test, the mathematical model of flow stress of 38MnVS6(Ti) under high temperature conditions, the mathematical model of microstructure under steady state conditions and the mathematical model of microstructure under unsteady state conditions are established, as shown in Table 1 and Table 1. 2 and Table 3.

[0038]

[0039]

[0040]

[0041]

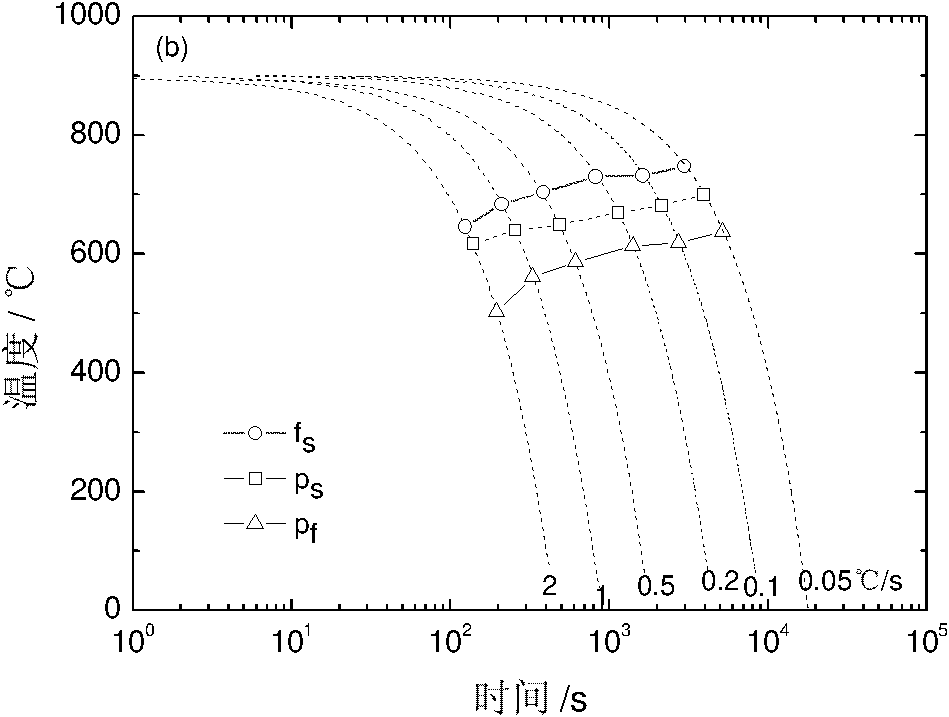

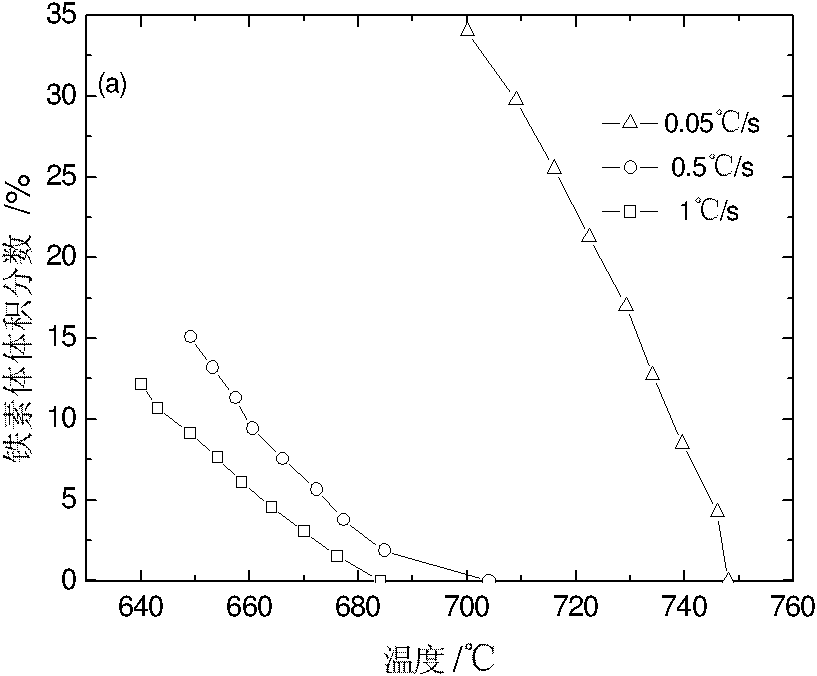

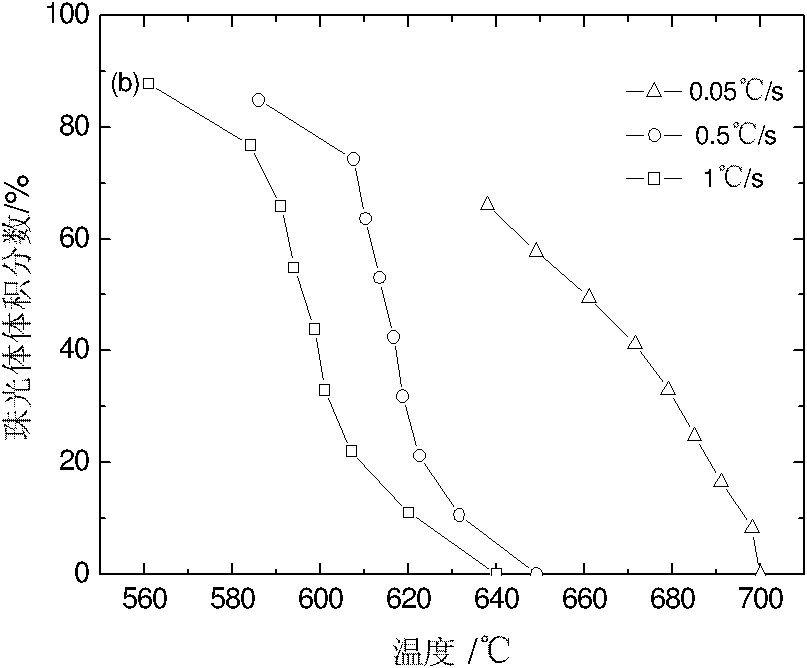

[0042] (2) Using the disclosed continuous cooling thermal simulation test method, the austenite to ferrite and pearlite continuous cooling transition curves of 38MnVS6 (Ti) were measured, as figure 1 shown. Using the published quantitative metallographic analysis method, the relationship between the volume fraction of ferrite and pearlite and the cooling rate in the continuous cooling process of 38MnVS6(Ti) is determined, respectively as follows figure 2 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com