Concrete structure FRP end anchor device

A concrete structure and end anchoring technology, applied in the direction of structural elements, building components, building structures, etc., can solve the problems of concrete beam damage and complicated construction, and achieve the effects of simple construction, avoidance of reinforcement failure, and improved ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

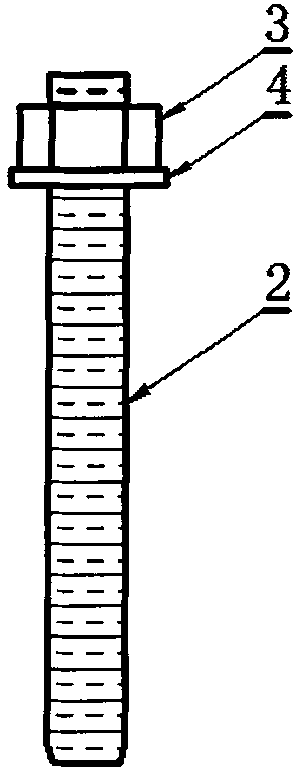

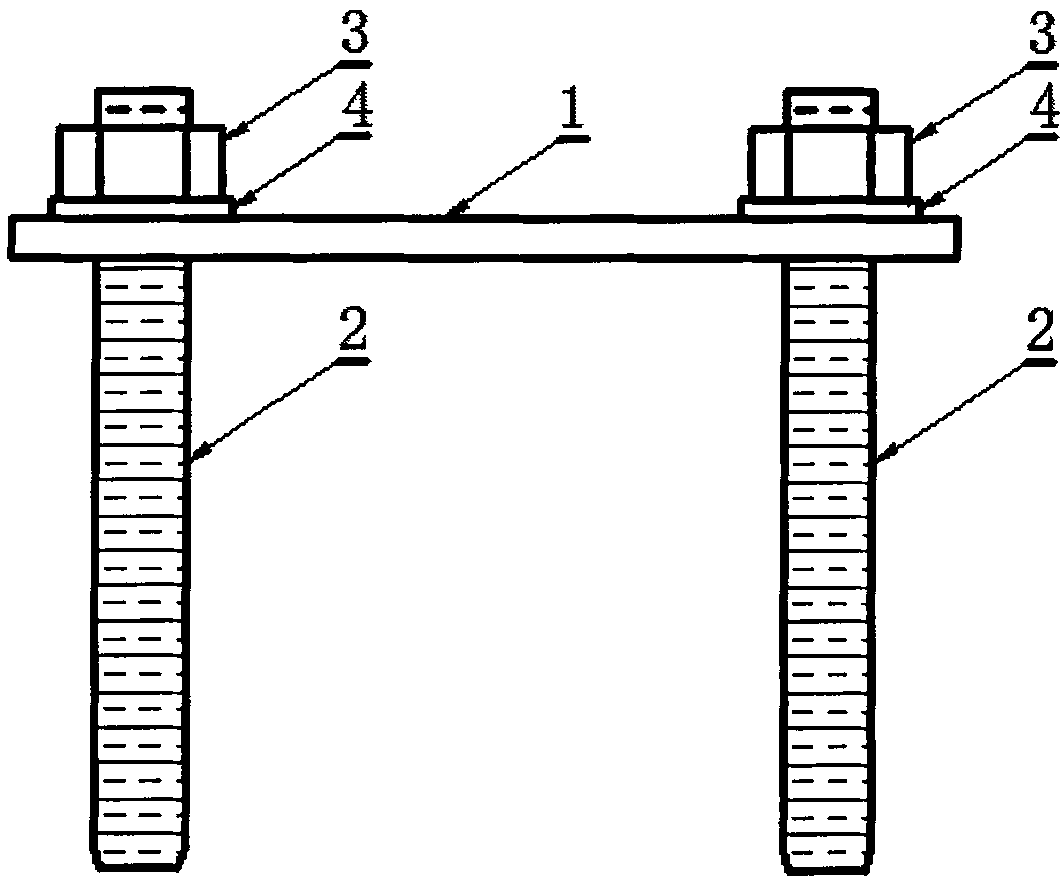

[0018] according to figure 1 , figure 2 As shown in the parts diagram, the concrete structure fiber cloth anchoring technology consists of a steel sheet 1, a screw rod 2, a nut 3 and a gasket 4. The steel sheet 1 is rectangular, and the edges and corners of the long sides are polished smoothly, and is used for winding and compressing the fiber cloth below it. Firstly drill a symmetrical hole with an electric drill at a predetermined position for fixing the screw rod 2 . During the drilling process, ensure the verticality of the drilling and the accuracy of the position. After cleaning the hole, inject adhesive into the hole, insert the screw 2 into the hole, and fix it at the corresponding position, and keep the screw 2 vertical during the insertion process. Then after the adhesive that fixes the screw rod 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com