Method for constructing ash concrete hollow partition plate

A slag concrete and partition board technology, which is applied in construction, building structure, processing of building materials, etc., can solve the problem that the flatness and verticality of the wall are not easy to control, it is unfavorable for cross-work of multiple types of work, and the height of masonry is limited. and other problems, to achieve the effect of reducing the cost of repairing materials and labor, the reputation of the society, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

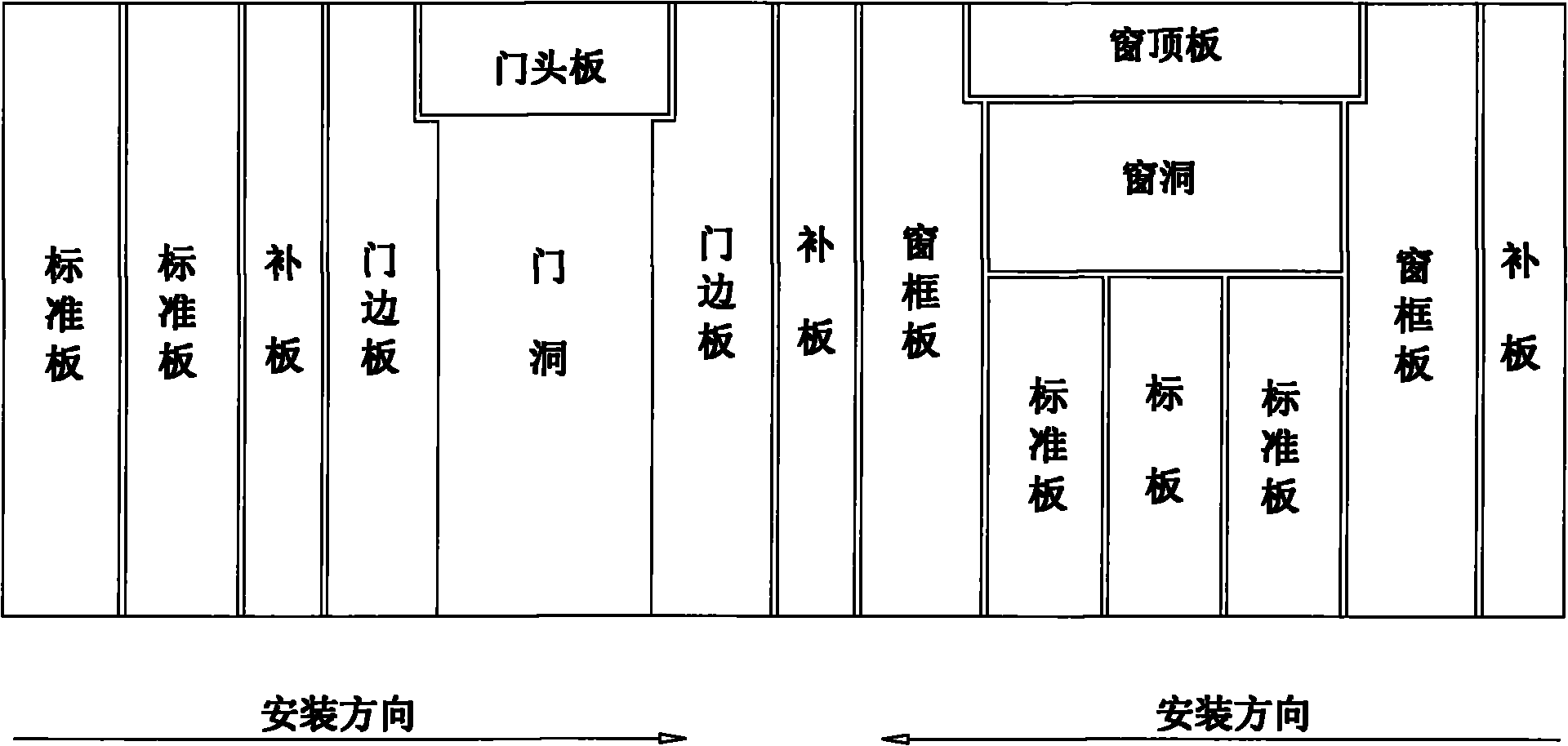

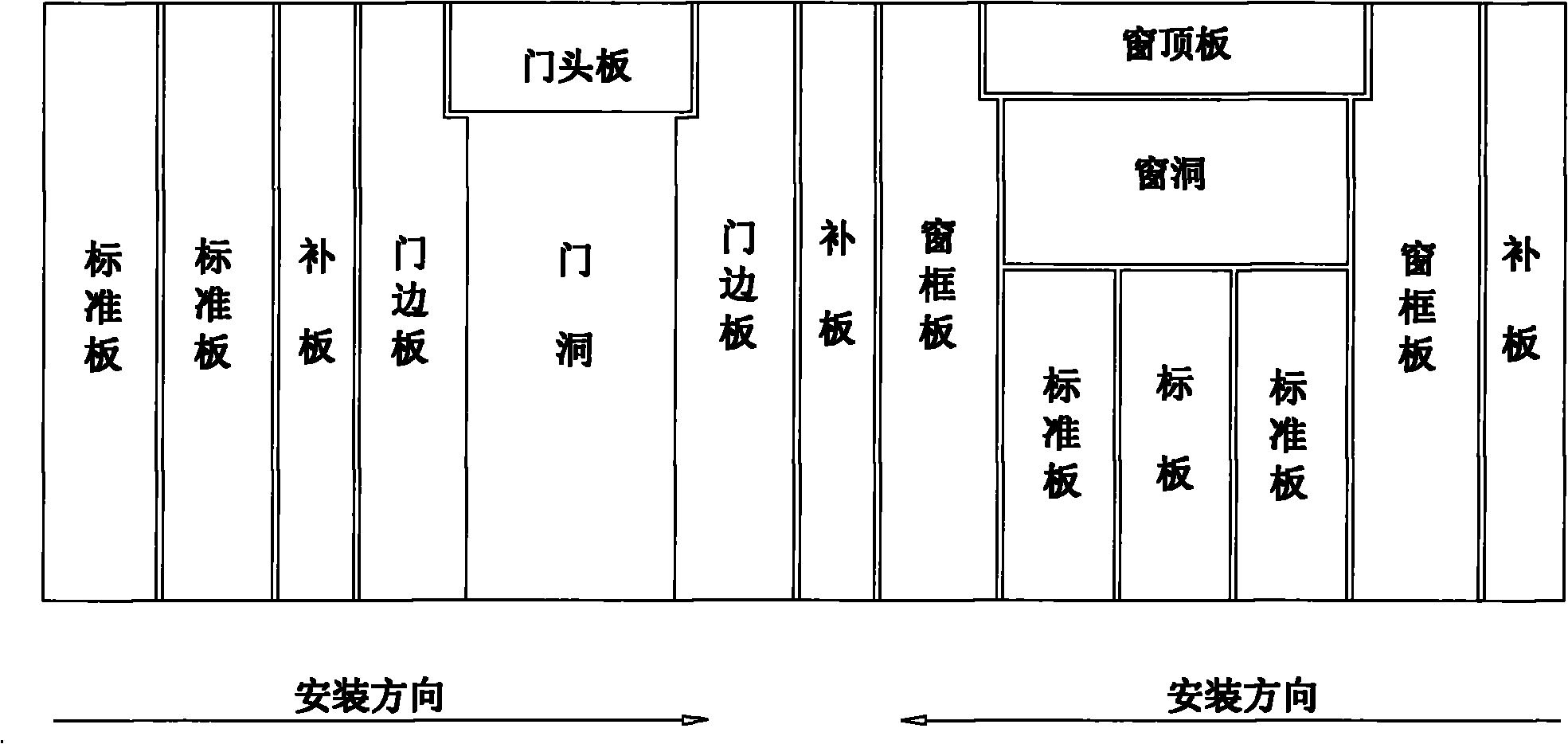

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific implementation steps.

[0036] 1. Clean up and install the hollow partition wall panel site, and prepare for construction

[0037] 1. Arrange a suitable site and range for stacking cinder concrete hollow partition wall panels.

[0038] 2. There are construction elevators (cages, tower cranes) for lifting lightweight wall panels, and the size can meet the requirements for lifting and transporting wall panels, and the lifting capacity can meet the requirements of the installation progress of lightweight wall panels.

[0039] 3. The structure of the construction layer has been completed, the building formwork, garbage and other sundries have been cleaned up, there is a working surface, and the handover of the upper and lower processes and the written handover list are completed, the light wall panels can enter the site for construction.

[0040] 4. There must be an axis, control line or ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com