Method for measuring firing temperature range of electrotechnical porcelain green body by using high-temperature dilatometer

A high-temperature expansion and firing temperature technology, applied in the direction of material thermal expansion coefficient, investigation stage/state change, etc., can solve the problems of high professional level requirements for operators, low labor efficiency, cumbersome methods, etc., and achieve less human influence factors, Ease of analysis, short-term effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Select a 220kV voltage level dry-molded electric porcelain green body, and its green body formula ratio is:

[0037] raw material name

Calcined kaolin

clay

Proportion

48%

20%

10%

22%

[0038] The basic physical indicators of the green body are as follows:

[0039] Body moisture

porosity content

0.55%

28.0%

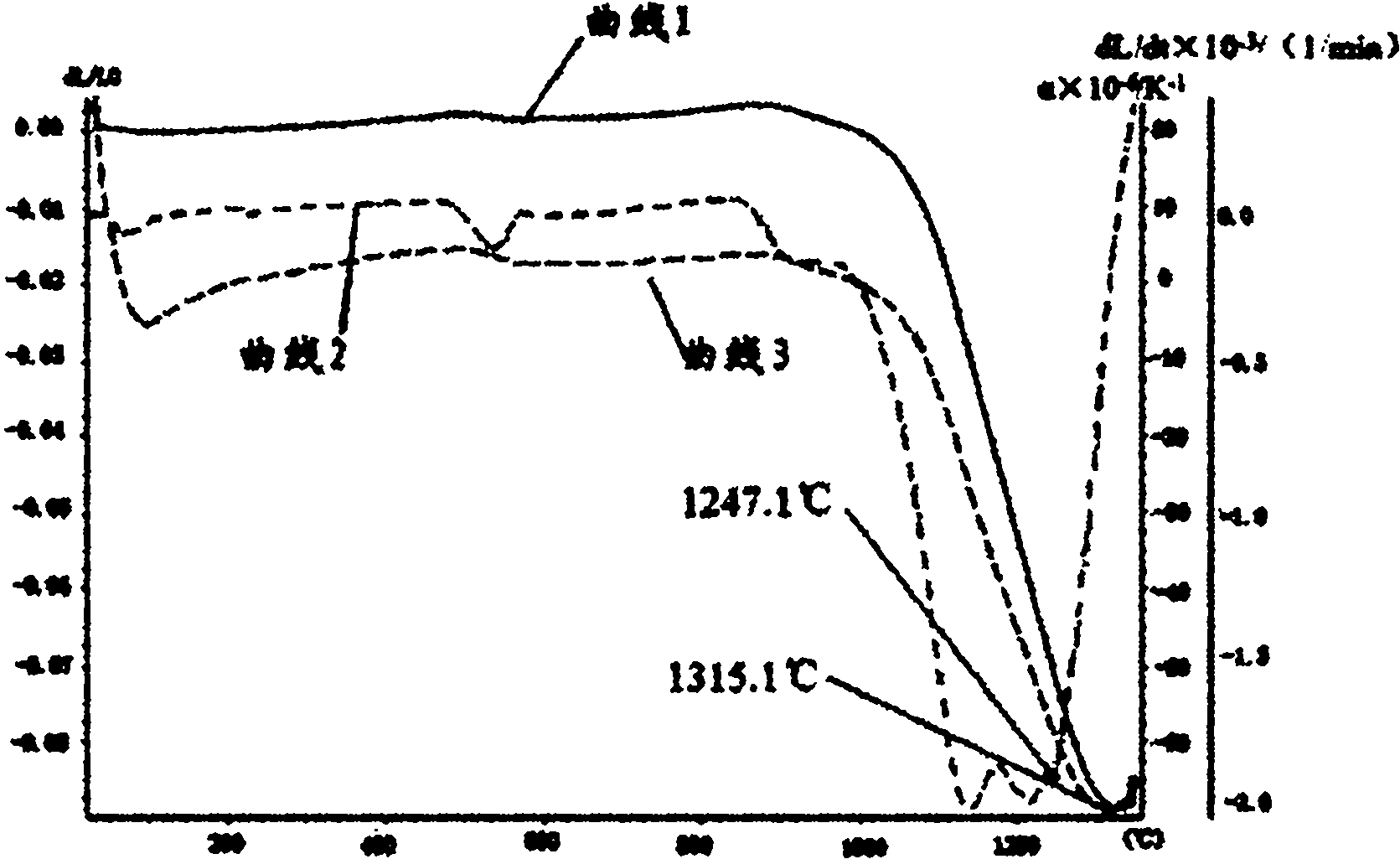

[0040] The green body is ready to be fired, and the highest firing temperature in the firing process needs to be tested and provided to facilitate production. To this end, take a sample on the green body, make a sample with a length of φ6×25mm, test it in a high-temperature dilatometer and obtain the linear expansion rate curve 1 at each temperature point, and perform a differential on the curve 1, get figure 1 The first differential curve 2 is shown; the coefficient of thermal expansion curve 3 is jointly calculated from the linear expansion rate curve 1 ...

Embodiment 2

[0058] Select a 110kV voltage level wet-process bushing electric porcelain body, and its body formula ratio is:

[0059] raw material name

illite clay

plastic clay

Proportion

40%

10%

12%

38%

[0060] The basic physical indicators of the green body are as follows:

[0061] Body moisture

porosity content

2.4%

25.5%

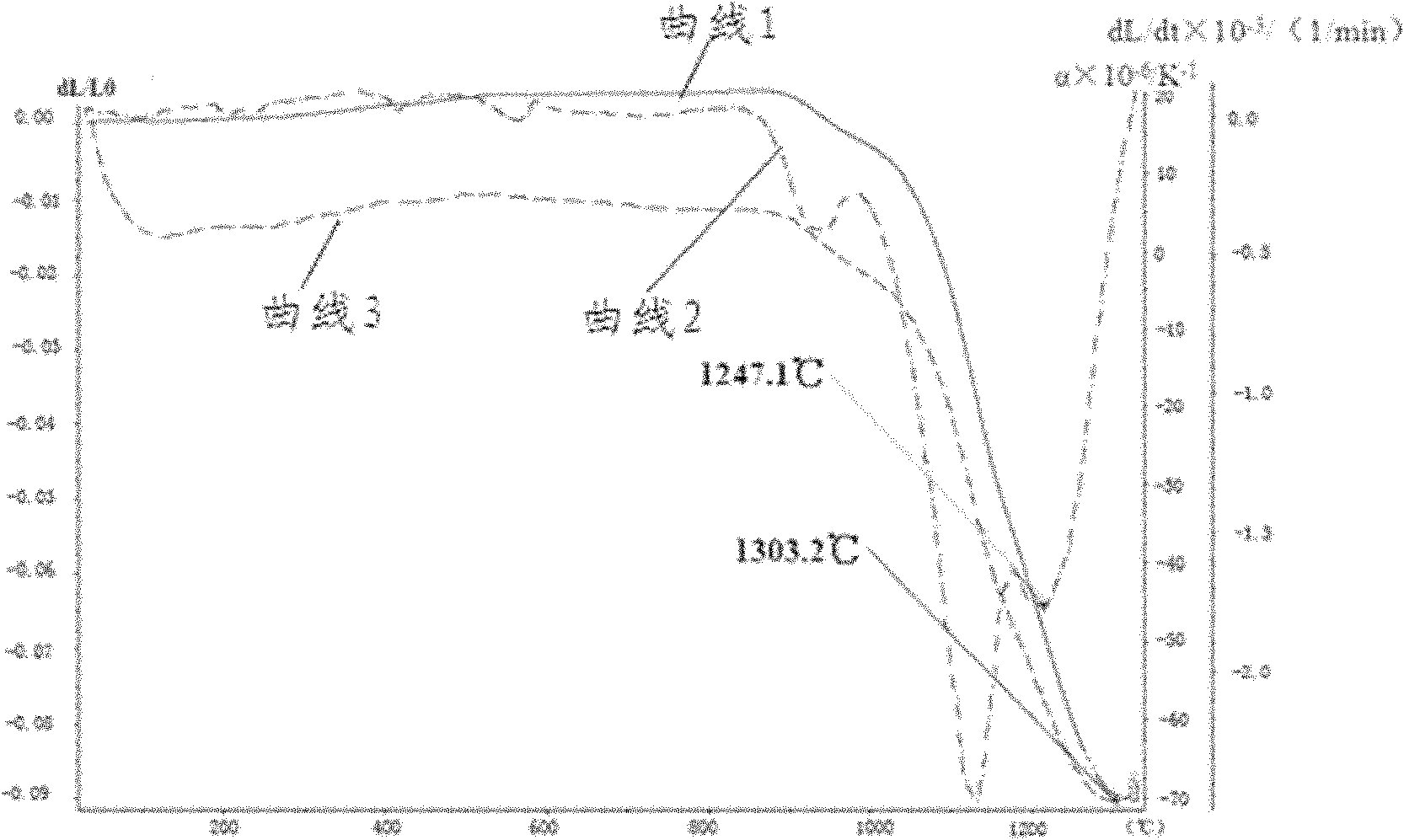

[0062] The green body is ready to be fired, and the highest firing temperature in the firing process needs to be tested and provided to facilitate production. To this end, take a sample on the green body, make a sample with a length of φ6×25mm, test it in a high-temperature dilatometer and obtain the linear expansion rate curve 4 at each temperature point, and perform a differential on the curve 4, get figure 2 The primary differential curve 5 is shown; the linear expansion coefficient curve 6 is jointly calculated from the linear expansion rate curve 4 t...

Embodiment 3

[0066] Select a wet-process rod-shaped electric porcelain body with a voltage level of 110kV, and the formula ratio of the body is:

[0067] raw material name

illite clay

plastic clay

Proportion

45%

12%

10%

35%

[0068] The basic physical indicators of the green body are as follows:

[0069] Body moisture

porosity content

2.5%

23.7%

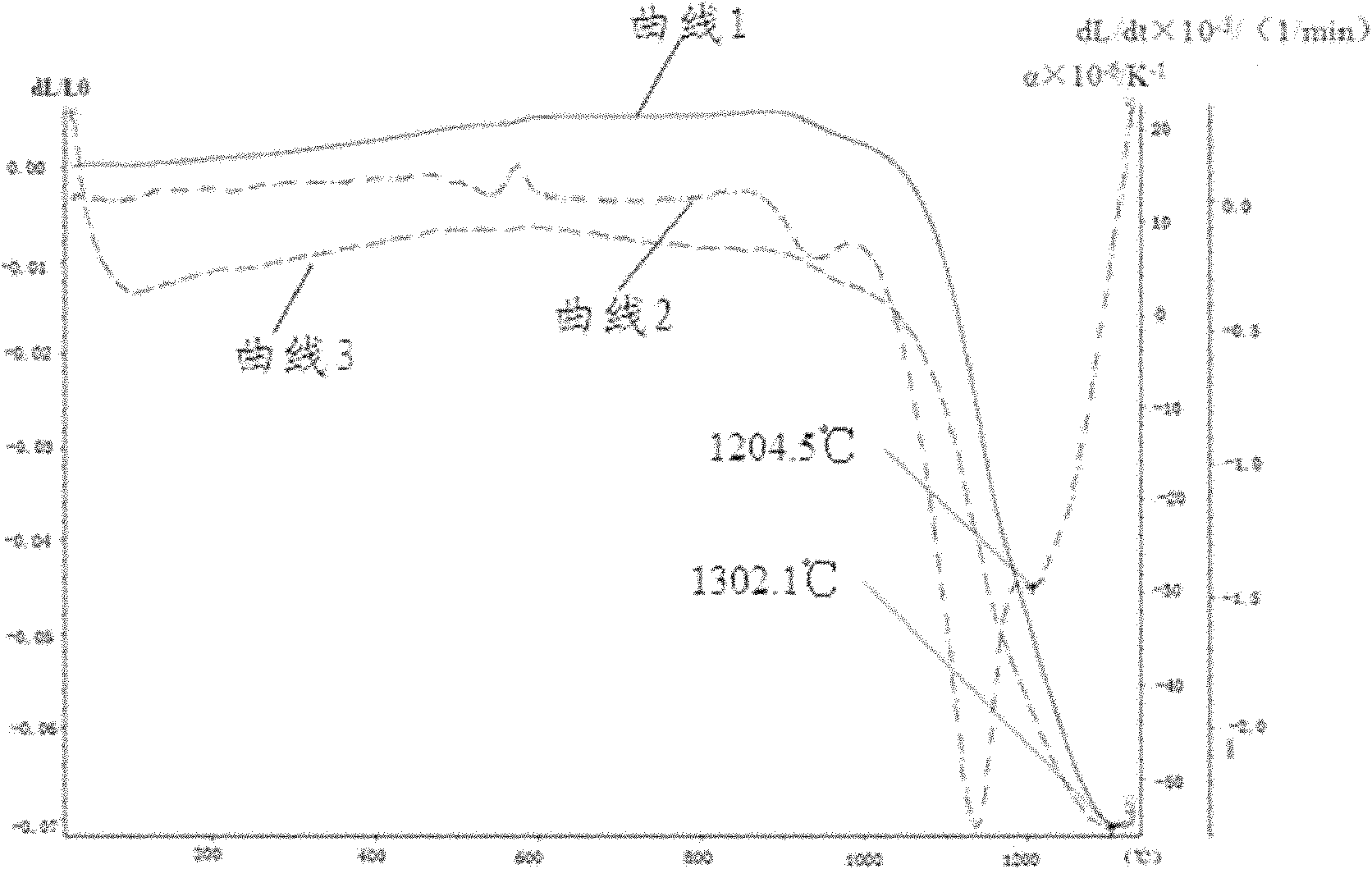

[0070] The green body is ready to be fired, and the highest firing temperature in the firing process needs to be tested and provided to facilitate production. To this end, take a sample on the green body, make a sample with a length of φ6×25mm, test it in a high-temperature dilatometer and obtain the linear expansion rate curve 7 at each temperature point, and perform a differential on the curve 7 once, get figure 2 The primary differential curve 8 is shown; the linear expansion coefficient curve 9 is jointly calculated from the linear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com